High Rejection,Fouling Resistant and High Flux RO Membrane ELements

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 0 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product introduction:

Product classification table

Nanofiltration Membrane Element:

Technical Parameters

Model | Permeate Flow GPD (m3/d) | Active Membrane Area ft2 (m2) | Stabilized Salt Rejection | Feed Spacer mil (mm) | Test Conditions |

MW-NF8040-375 | 10500(39.7) | 375(34.9) | 97% | 28(0.7) | 75psi/2000ppmMgSO4 |

11000(41.6) | 375(34.9) | 30-50% | 28(0.7) | 75psi/1000ppmNaCl | |

MW-NF8040-400 | 12000(45.4) | 400(37.2) | 97% | 28(0.7) | 75psi/2000ppmMgSO4 |

13000(49.2) | 400(37.2) | 30-50% | 28(0.7) | 75psi/1000ppmNaCl | |

MW-NF4040 | 2400(9.1) | 85(7.9) | 97% | 28(0.7) | 75psi/2000ppmMgSO4 |

2650(10) | 85(7.9) | 30-50% | 28(0.7) | 75psi/1000ppmNaCl |

1.All performance data are collected at 25℃ (77℉), PH7.4 - 7.6 and 15% recovery rate.

2.Permeate flows for single element may vary ± 15%.

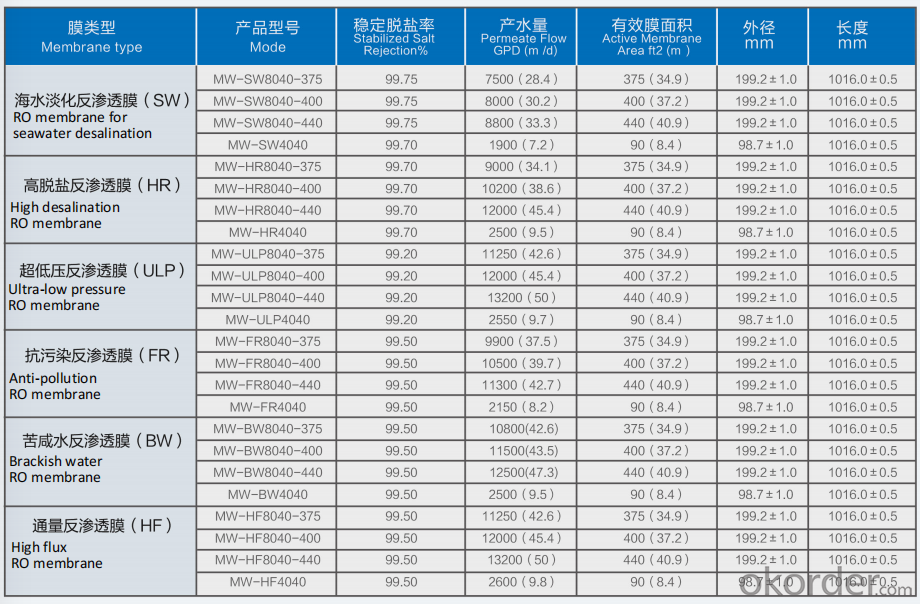

Low Pressure Memrane ELements:

Technical Parameters

Model | Permeate Flow GPD (m3/d) | Active Membrane Area ft2 (m2) | Stabilized Salt Rejection | Feed Spacer mil (mm) | Test Conditions |

MW-ULP8040-375 | 11250(42.6) | 375(34.9) | 99.2% | 28(0.7) | 150psi/1500ppmNaCl |

MW-ULP8040-400 | 12000(45.4) | 400(37.2) | 99.2% | 28(0.7) | 150psi/1500ppmNaCl |

MWULP8040-440 | 13200(50) | 440(38.1) | 99.2% | 28(0.7) | 150psi/1500ppmNaCl |

MW- ULP4040 | 2550(9.7) | 85(7.9) | 99.2% | 28(0.7) | 150psi/1500ppmNaCl |

1. All performance data are collected at 25℃ (77℉), PH7.4 - 7.6 and 15% recovery rate.

2. Permeate flows for single element may vary ± 15%.

High Rejection RO Membrane ELements

Technical Parameters

Model |

Permeate Flow GPD (m3/d) | Active Membrane Area ft2 (m2) | Stabilized Salt Rejection | Feed Spacer mil (mm) | Test Conditions |

MW-HR8040-375 | 11250(42.6) | 375(34.9) | 99.3% | 28(0.7) | 225psi/2000ppmNaCl |

MW-HR8040-400 | 12000(45.4) | 400(37.2) | 99.3% | 28(0.7) | 225psi/2000ppmNaCl |

MW-HR8040-440 | 13200(50) | 440(38.1) | 99.3% | 28(0.7) | 225psi/2000ppmNaCl |

MW-HR4040 | 2500(9.5) | 85(7.9) | 99.5% | 28(0.7) | 225psi/2000ppmNaCl |

1. All performance data are collected at 25℃ (77℉), PH7.4 - 7.6 and 15% recovery rate.

2. Permeate flows for single element may vary ± 15%.

Operating Conditions

Maximum Operating Temperature | 45℃(113℉) |

Maximum Operating Pressure | 600psi(41bar) |

Maximum Pressure Drop (single element) | 15psi(1.0bar) |

pH Range for Continuous Operation | 3.0-10.0 |

pH Range for Cleaning | 1.0-13.0 |

Chlorine Tolerance | <0.1ppm |

Maximum Feed SDI15 | 5.0 |

Maximum Feed Flux | 17.0m3/h |

Fouling Resistant RO Membrane ELements

Technical Parameters

Model | Permeate Flow GPD (m3/d) | Active Membrane Area ft2 (m2) | Stabilized Salt Rejection | Feed Spacer mil (mm) | Test Conditions |

MW-FR8040-375 | 9400(35.6) | 375(34.9) | 99.5% | 28(0.7) | 225psi/2000ppmNaCl |

MW-FR8040-400 | 9900(37.4) | 400(37.2) | 99.5% | 28(0.7) | 225psi/2000ppmNaCl |

MW-FR8040-440 | 11300(42.7) | 440(38.1) | 99.5% | 28(0.7) | 225psi/2000ppmNaCl |

MW-FR4040 | 2150(8.2) | 85(7.9) | 99.5% | 28(0.7) | 225psi/2000ppmNaCl |

1. All performance data are collected at 25℃ (77℉), PH7.4 - 7.6 and 15% recovery rate.

2. Permeate flows for single element may vary ± 15%。

Operating Conditions

Maximum Operating Temperature | 45℃(113℉) |

Maximum Operating Pressure | 600psi(41bar) |

Maximum Pressure Drop (single element) | 15psi(1.0bar) |

pH Range for Continuous Operation | 3.0-10.0 |

pH Range for Cleaning | 2.0-12.0 |

Chlorine Tolerance | <0.1ppm |

Maximum Feed SDI15 | 5.0 |

Maximum Feed Flux | 17.0m3/h |

Seawater RO Membrane ELements

Technical Parameters

Model | Permeate Flow GPD (m3/d) | Active Membrane Area ft2 (m2) | Stabilized Salt Rejection | Feed Spacer mil (mm) | Test Conditions |

MW-SW8040-375 | 7500(28.4) | 375(34.9) | 99.7% | 28(0.7) | 800psi/32000ppmNaCl |

MW-SW8040-400 | 8000(30.2) | 400(37.2) | 99.7% | 28(0.7) | 800psi/32000ppmNaCl |

MW-SW8040-440 | 8800(33.3) | 440(38.1) | 99.7% | 28(0.7) | 800psi/32000ppmNaCl |

MW-SW4040 | 1950(7.4) | 85(7.9) | 99.7% | 28(0.7) | 800psi/32000ppmNaCl |

1.All performance data are collected at 25℃ (77℉), PH7.4 - 7.6 and 7% recovery rate.

2.Permeate flows for single element may vary ± 15%.

Operating Conditions

Maximum Operating Temperature | 45℃(113℉) |

Maximum Operating Pressure | 1200psi(83bar) |

Maximum Pressure Drop (single element) | 15psi(1.0bar) |

pH Range for Continuous Operation | 3.0-10.0 |

pH Range for Cleaning | 2.0-12.0 |

Chlorine Tolerance | <0.1ppm |

Maximum Feed SDI15 | 5.0 |

Maximum Feed Flux | 17.0m3/h |

High Flux RO Membrane ELements

Technical Parameters

Model | Permeate Flow GPD (m3/d) | Active Membrane Area ft2 (m2) | Stabilized Salt Rejection | Feed Spacer mil (mm) | Test Conditions |

MW-HF8040-375 | 9000(34.1) | 375(34.9) | 99.5% | 28(0.7) | 225psi/2000ppmNaCl |

MW-HF8040-400 | 10200(38.6) | 400(37.2) | 99.5% | 28(0.7) | 225psi/2000ppmNaCl |

MW-HF8040-440 | 12000(45.4) | 440(38.1) | 99.5% | 28(0.7) | 225psi/2000ppmNaCl |

MW-HF4040 | 2500(9.5) | 80(7.4) | 99.5% | 28(0.7) | 225psi/2000ppmNaCl |

1.All performance data are collected at 25℃ (77℉), PH7.4 - 7.6 and 15% recovery rate.

2.Permeate flows for single element may vary ± 15%.

Operating Conditions

Maximum Operating Temperature | 45℃(113℉) |

Maximum Operating Pressure | 1000psi(69bar) |

Maximum Pressure Drop (single element) | 15psi(1.0bar) |

pH Range for Continuous Operation | 3.0-10.0 |

pH Range for Cleaning | 2.0-12.0 |

Chlorine Tolerance | <0.1ppm |

Maximum Feed SDI15 | 5.0 |

Maximum Feed Flux | 17.0m3/h |

Brackish Water RO Membrane ELements

Technical Parameters

Model | Permeate Flow GPD (m3/d) | Active Membrane Area ft2 (m2) | Stabilized Salt Rejection | Feed Spacer mil (mm) | Test Conditions |

MW-BW8040-375 | 11260(42.6) | 375(34.9) | 99.5% | 28(0.7) | 225psi/2000ppmNaCl |

MW-BW8040-400 | 11500(43.5) | 400(37.2) | 99.5% | 28(0.7) | 225psi/2000ppmNaCl |

MW-BW8040-440 | 12000(45.4) | 440(38.1) | 99.5% | 28(0.7) | 225psi/2000ppmNaCl |

MW- BW4040 | 2050(7.7) | 85(7.9) | 99.5% | 28(0.7) | 225psi/2000ppmNaCl |

1.All performance data are collected at 25℃ (77℉), PH7.4 - 7.6 and 15% recovery rate.

2.Permeate flows for single element may vary ± 15%.

Operating Conditions

Maximum Operating Temperature | 45℃(113℉) |

Maximum Operating Pressure | 600psi(41bar) |

Maximum Pressure Drop (single element) | 15psi(1.0bar) |

pH Range for Continuous Operation | 3.0-10.0 |

pH Range for Cleaning | 2.0-12.0 |

Chlorine Tolerance | <0.1ppm |

Maximum Feed SDI15 | 5.0 |

Maximum Feed Flux(BW-8040) | 17.0m3/h |

Maximum Feed Flux(BW-4040) | 3.7m3/h |

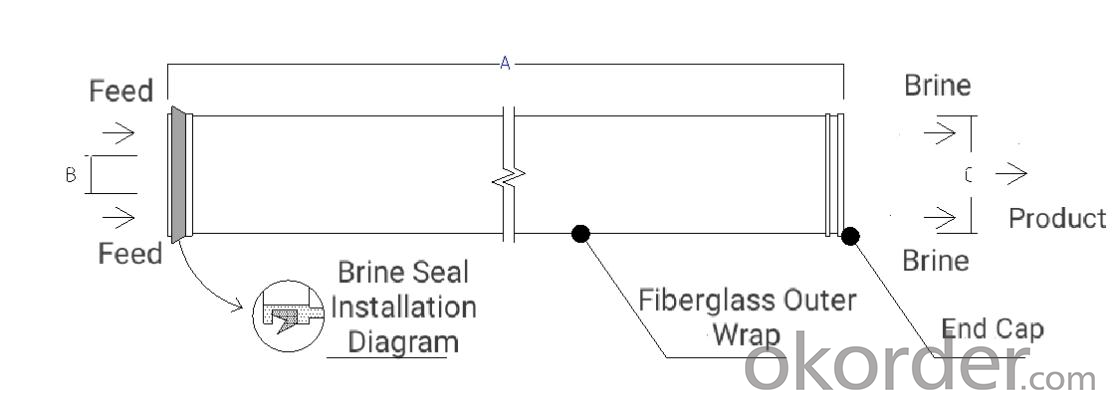

Membrane Element Dimension:

Model | Dimensions - Inches (mm) | ||

A | B | C | |

MW-HR8040-375 | 40.0(1016) | 1.12 (28.5) | 7.9(201) |

MW-HR8040-400 | 40.0(1016) | 1.12 (28.5) | 7.9(201) |

MW-HR8040-440 | 40.0(1016) | 1.12 (28.5) | 7.9(201) |

Product Advantage:

1.The world's leading mature technology

2.Non-standard customized advanced manufacturing equipment

3.High throughput:Optimize raw materials, adjust casting film and coating process, improve permeability.

4.High desalination:The formulation was optimized to regulate the crosslinking degree of polyamine and the morphology and structure of the functional layer to improve the selective permeability.

5.Resistance to pollution:Through special additives and post-treatment process, the separation membrane can effectively reduce the adsorption and retention of pollutants and improve the anti-pollution ability.

6.Stability:The excellent chemical stability of each material ensures the solvent resistance and acid and alkali resistance of the separation film, improves the service life of the separation film and expands its application range.

7.Ultra-thin functional layers achieve performance leadership

8.Multi-layer composite structure ensures stable quality

Operation Notes:

1.Before installation please don't unpack the membrane elements, store in a dry and ventilated place away from light with temperature between 10 and 35C. Elements should be handled with care when in transit.

2.Prohibit brutal installation such as metal hammer beating, follow starting procedure strictly in order to prevent membrane damage caused by excessive impact.

3.Carry out instrument calibration, membrane pretreatment and system inspection before system startup and membrane elements loading.

4.Try to avoid hydraulic impact or cross-current fluctuation on the spiral-wound membrane elements and start system gradually.

5.Monitor water quality of pretreatment and discharge water in the first hour of the first use.

6.If system shutdown short-term (within 15 days), please close valve of the system to keep membrane elements moist and wash regularly.

7.Don't produce backpressure in any case.

8.Maximum allowable pressure drop of membrane shell is 50psi (3.4bar).

9.If system shutdown for a long time, please soak membrane elements in the preservative solution to prevent bacterial growth.

10.Please ensure chemicals and lubricants don't affect membrane elements adversely in use.

11.If membrane system performance drops by 10% under standard conditions, or membrane fouling and scaling occur, please rinse membrane elements according to regulation process immediately.

12.The manufacturer won't provide warranty service, if the operating requirements and conditions aren't complied with.

Product Application:

Drinking water, industrial water purification, food and medicine industry material concentration and separation, desalination and decolorization, material recycling; Municipal tap water, groundwater, surface water desalination water treatment for raw water; Seawater desalination, desalination and treatment of high concentration bitter brine, concentration and reuse of high salt wastewater; Medical pure water preparation, food, beverage and other industries of high pure water and material separation system; Water treatment areas with special sanitary requirements.

Quality control:

Before production, our engineer will work out the production plan in strict accordance with the requirements. After the production, we also have quality inspector responsible for inspection. All products have to be inspected before they go out.

1. All raw materials are inspected as soon as they arrive at the factory. The quality of the raw materials is excellent.

2. Check the production process and tools used during production.

3. The quality and packaging of all products shall be completed after the final inspection.

Scope of Business:

1. Technology research and development, Product manufacture.

2. Equipment integration, Complete set of technologies.

3. Water treatment project Design-Build-Operation.

4. To build a complete industrial chain of water treatment business with membrane process and biofilm process as the core technologies.

- Q: How does the blue water purifier filter dirt, mud, water?

- only RO reverse osmosis water purifier can filter water heavy metals, bacteria and viruses etc..

- Q: Does the tank filter need to work all the time?

- In principle, usually 24 hours, the maintenance of good, with a long time, if encountered in the following several circumstances, to be free to grasp the noise; if the sound does not affect your rest, it is best to always open

- Q: My home water is well water. What do I need to filter?

- (in fact, most of the water treatment plants are not very complicated at present and the water quality of the water sources is ideal.).

- Q: What's the difference between a household scale filter and a softened water equipment?

- both have the function of removing the scale, but the use of low cost, without subsequent maintenance, the water amount is larger, less expensive

- Q: What brand of water filter is good???

- In fact, the quality of the water filter is not to look at the brand, but depending on the quality of the local water quality and your needs.

- Q: Is it harmful to drink filtered water regularly?

- Magnetized water refers to water field, cross cutting lines, the molecular structure of water change to complete the process of magnetization of water. It is said that this water has softened heart, cerebrovascular, prevention and treatment of bile, kidney stones, but still needs long-term practice to verify and carry out scientific proof. Mineral water refers to the groundwater that flows through some of the rocks in the depth of the groundwater.

- Q: The water filtered by the water purifier and the organic minerals in it? Will it decrease if there is?

- to boil drinking water machine out of the water is what are not included, is pure water, drinking water can be directly

- Q: How can the aquarium filter the cotton to prevent the water from spilling out?

- The fish tank filters the cotton without chlorine, so it can not pollute the environment after being treated.

- Q: Can the water filter filter the oil in the water?

- In general, there is no oil in the tap water. If it is cooking oil, it may not be filtered out, but it may be possible if it is the so-called industrial oil.

- Q: Can household water filters filter out rust water?

- General household water purifier can be filtered out

Send your message to us

High Rejection,Fouling Resistant and High Flux RO Membrane ELements

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 0 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Lianyungang Zhongfu Lianzhong Composites Group Co.,Ltd.

Lianyungang Zhongfu Lianzhong Composites Group Co.,Ltd.