High range polycarboxylate superplasticizer concrete admixtures

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 500000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

High range polycarboxylate superplasticizer

concrete admixtures

Description

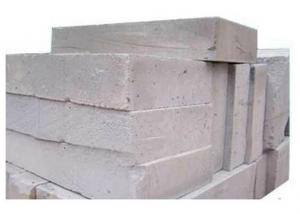

HL-800 is a new type of polycarboxylate superplasticizer which has a high water reducing rate. As the third generation of water reducers, it is very effective in producing concretes with different levels of workability including applications that require the use of self-consolidating concrete(SCC). It complies with ASTM C 494 requirements for Type F, high-range water-reducing admixtures.

Application

HL-800 is suitable for ready-mixed, pumping, hot weather concrete and the precast elements used in the construction which requires good workability and high early and final strengths. It can be applied in the preparation of various concrete of C40 and above grade with low water/cement ratio. When applied in preparation of concrete of higher than C80, it is recommended to conduct tests before bulk production.

Properties

Items | HL-800 |

Appearance | Colorless or light yellow liquid |

Density(g/cm3) | 1.09±0.02 |

pH value(%) | 4~7 |

Solid Content (%) | 40~50±1 |

fluidity of cement(mm) | ≥240 |

chlorine ion content (according to solid content changing)(%) | ≤0.02 |

Total alkali Content (according to solid content changing)(%) | ≤2 |

formaldehyde content (according to solid content changing)(%) | ≤0.01 |

Product Features:

1) Polycarboxylate-series High-performance Water Reducing Agent is a light beige

oily liquid. I t is non-toxic, odorless, non-inflammable, and environmentally-friendly.

2)With a high water reducing rate, it is especially applicable to C50 cement and cements

of a higher standard.

3)Its early strength and reinforcement role is obvious.Due to micro-entraining, it can

effectively improve concrete durability performance, e .g. impermeability, anti-freeze.

4)It is characterized by good flowing retention ability, low slump loss, and good

compatibility with cement.

5)With a low alkali content, it can reduce concrete' s alkali-aggregate reaction apparently.

6)Distortion performance: after being added with Polycarboxylate-series High performance Water Reducing Agent,

concrete seldom becomes distorted as it shrinks. Thus the

possibility of distortion cracking caused by concrete dry shrinkage or creeping is decreased.

7)It has a good water retaining performance. Even under the condition of a high dosage,

concrete will not bleed water or become isolated easily. Compared withnaphthalene-series and

sulfamate-series high-efficiency water reducing agents, this product has an obvious advantage.

Dosage

This product recommended content is 0.25% -0.85% of the total weight of cementitious

material, actually content should be experimentally determined.

Usage

1. HL-800 is always diluted to 10% to 20% concentration for use.

For example, to make 1 ton of HL-800 solution(10%), please fully dilute 200kg of HL-800 (50%) into 800kg of water.

2. When the weather is hot, making concrete with HL-800, a certain amount of retarding agent and air-entraining agent need to be added in the HL-800 solution (10%). On special occasions when slump loss of concrete speeds up and segregation appears after casting, it's necessary to add plastic retaining agent (or add our product of SR-1). Here's the general formula to compound HL-800.

HL-800 solution (10%): 980kg

Retarding Agent: 15-20kg

Air-entraining Agent: 2kg

The dosage of the finished product is 2.0-3.0% by weight of cement.

Packaging, transport and storage

1.It is packed in Flexitank in 20ft container, 220kg plastic drums or 1000Liter per IBC Tank, Other special package can also be available according to prior consultation.

2.Special measures should be taken to ensure entire package. Keep waterproof during transportation.

3.Dry and well ventilated warehouse is needed for storage. Quality guarantee of Polycarboxylate Superplasticizer is 12 months under normal conditions. If storage has surpassed the time, test must be done to confirm the validity.

Send your message to us

High range polycarboxylate superplasticizer concrete admixtures

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 500000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords