High Pressure GRE Tubing Used in the Oil Field

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 1000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

API Hot Spring Pipe

1.Standard:API,ASTM,ISO,GB, etc

2.Anti-corrosion & high strength

3.Long service time

4.Low costs

GRE (Glass Reinforced Epoxy)

Some times, GRE and FRP/GRP (Fiber/Glass Reinforced Plastic) are regarded as the same

material with different names, but in most cases, since GRE choice epoxy resin as material,

it has stronger performances.

It is the thermosetting plastic products combining the reinforced material of fiberglass roving with the base material of epoxy resin.

It is made by mechanical filament wound process controlled by computer.

So it is a kind of composite material.

The GRE pipe offers a unique combination of chemical resistance, size stability, high strength, and thermal/electric non-conductivity.

So the GRE pipe can be used in the fields of chemical anti-corrosion, construction, electric insulation, power development etc.

Features:

1. Anti corrosion

2. High strength, more safety

3. More than 30 years service life

4. Light weight, easy installation and keeping cost

5. Flexible design and shorter reform term

6. No medium pollution

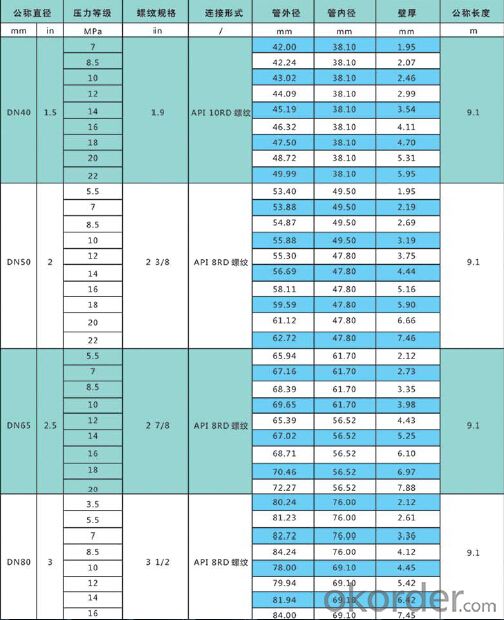

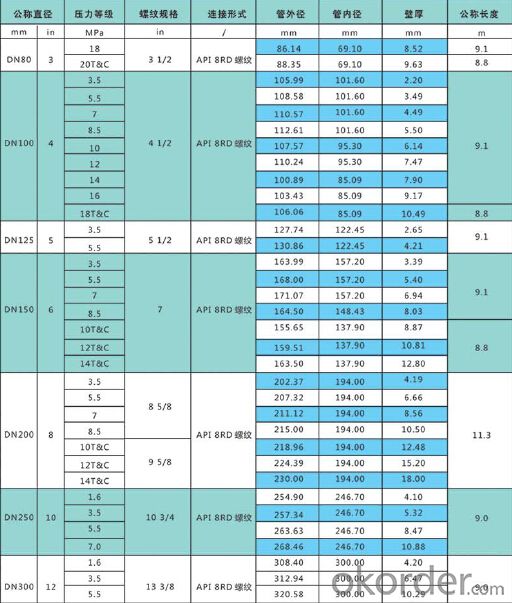

Technical Table

Applications:

1.Oil, petroleum, natural gas pipeline

2.Irrigation, hot spring, city water pipeline

3.Brine delivery pipeline

4.Other liquid transport pipeline

Strength:

1.High quality

We're state owned manufacturer with registered capital RMB 200 million specialized in this area.Standard:API-15HR,API-15LR,ISO9001,GB,etc.

2.Competitive price

Our raw material is from PPG SINOMA JINJING FIBERGLASS CO.,LTD, a JV enterprise

invested by our company and PPG industries to ensure high quality and low costs.

3.Great production capacity and short delivery time.We have 16 production lines for GRE pipe, with annual production capacity of 16000MT.

Pitcures of our factory:

FAQ of GRE pipes:

Q1: What’s the performance standards?

Lianzhong pipe is designed to meet all of these ASTM , AWWA, BS, DIN standards.

Q2: What’s the qualification testing for the products?

Lianzhong pipe has been rigorously tested to verify conformance to the ASTM D3262, ASTM D3517, AWWA C950 and DIN 16868 requirements

Q3: How long can I receive my goods?

A: Usually, we will deliver products within 20 days after the contract is signed. Delivery time is negotiable when necessary.

- Q: FRP pipe price

- The price range of raw material resin is about 10000/ tons to 60000/ tons.

- Q: Is the installation of FRP pipes required qualification?

- At present, for purely glass fiber steel, there is no uniform international standards, installation workers must have qualified installation.

- Q: Glass fiber reinforced plastic pipe to withstand 1.0MPa pressure, pipe wall to do how much thickness?

- This depends on the size of the pipe diameter, the greater the diameter, the thicker the wall.

- Q: What are the materials used in smoke exhaust pipes?

- In the production of the coal mine exhaust pipe is indispensable, in underground work, because from the ground, the air is not easy to reach, easy to accumulate large amounts of methane gas, these gases will need ventilation pipe timely transferred to the ground to prevent the explosion in the coal mine ventilation pipe, the material is generally iron and plastic.

- Q: Galvanized steel sheet and inorganic glass fibre reinforced plastic pipe are calculated according to this norm or norm

- The use of a fixed fare set without further consideration to duct losses has been included in the quota project

- Q: How to open a DN300 port on the DN600 GRP pipe and install the DN300 gate?!

- A 300 hole bonding a short tube, in the installation of a valve (see what install valves, iron needs a steel plastic conversion, direct bonding glass steel flange, a glass tube) special glue (a few years ago had forgotten what, like what's called 507), this thing is good to buy special glass steel where there is, the effect is quite good

- Q: How is the glass reinforced septic tank and the cement drain pipe connected?

- The interface can be bonded with epoxy resin adhesive. The epoxy resin strongly adhere to the two materials, but the bonding surface must be clean.

- Q: What kind of material are the flanges and valves on the GRP pipe?

- Construction: glass fiber reinforced plastic can be threaded joints, easy to install, better quality, PVC generally glue adhesive, due to temperature problems, quality is difficult to ensure;

- Q: What are the construction methods of glass fiber reinforced plastic paint anticorrosive pipes?

- Oil and gas pipelines used for twenty years, basically no corrosion phenomenon. As part of a group of coal tar epoxy primer and topcoat are based on epoxy resin and coal tar as the main film-forming material, add a variety of anti rust paint, insulating filler, toughening agent, leveling agent, diluent, anti settling agents and other materials, the B component is modified amine curing agent or curing agent the main material, adding fillers. When the product is sold, the A and B parts are supplied together, and the mixture is mixed in proportion during construction.

- Q: What kind of diamond saw blade for cut glass steel pipe?

- Diamond saw blade is a kind of cutting tool. It is widely used in the processing of concrete, refractory, stone, ceramics and other hard and brittle materials. The diamond saw blade is mainly composed of two parts: matrix and cutter head. The matrix is the main supporting part of the bond of the cutter head, the cutter head is the cutting part during use, the cutter head can be in use and constantly consumed, and the matrix is not, the cutter head is able to cut the role because it contains diamond, diamond as the hard material of it friction cutting object is processed in the knife head. The diamond particles are wrapped in metal inside the cutter head.

Send your message to us

High Pressure GRE Tubing Used in the Oil Field

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 1000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords