High Flame retardant PVC jacket compound

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 3000 Tons kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

HighFlame Retardant PVC Jacket Compound

I. Type and application

Type | Product | Application and Cable Specification |

7023N-32 | 70℃High flame retardant PVC jacket compound | High flame retardant PVC jacket compound for cables and wires with temperature rating of conductor at 70℃. |

7331N | 70℃High flame retardant PVC jacket compound | High flame retardant PVC jacket compound for cables and wires with temperature rating of conductor at 70℃. And pass the CMR grade burning test. Meeting low smoke and low halogen requirements. |

2833N-40 | 75℃High flame retardant PVC jacket compound | High flame retardant PVC jacket compound for cables and wires with temperature rating of conductor at 75℃. And pass the CMR grade burning test. Meeting low smoke and low halogen requirements. |

2833N-48 | 75℃High flame retardant PVC jacket compound | High flame retardant PVC jacket compound for cables and wires with temperature rating of conductor at 75℃. And pass the CMR/ CMP grade burning test. Meeting low smoke and low halogen requirements. |

II. Product Description

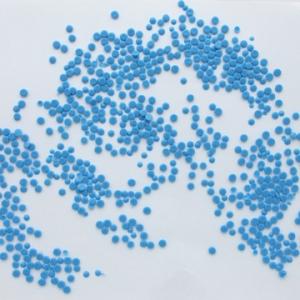

Flameretardant PVC jacket compound for wires and cables, based on PVC resin, is madeinto granula by mixing, plastification and granulation with adding plasticizer,stabilizing agent, flame retardant and etc. The products meet various specialrequirements, such as different hardness, UV stable, environment friend (RoHs,REACH, PAHs, chlorinated alkanes free, phthalate free, and etc.), sub-shine and fog surface, low temperatureresistant, PS/ABS transfer proof, rodent-repellent, termite-repellent, and etc.

III. Processing:

Itis recommended that compound should be processed with common extruder having aminimum L/D ratio of 20.

Thefollowing temperature(℃) profile of extruder is recommended:

Zone | Zone 1 | Zone 2 | Zone 3 | Zone 4 | Head | Die |

Temperature ℃ | 140 | 160 | 170 | 175 | 180 | 175 |

IV. Storage and transport

Packaging:25kg/bag, PE membrane inside bag and Kraft outsidebag.

Storageand transport: Avoiding in direct sunlight and weathering. The storage placeshould be in clean, cool, dry, and ventilated conditions.

V. Properties

Table

Item | Unit | Standard Value | |||

7023N-32 | 7331N | 2833N-40 | 2833N-48 | ||

Tensile Strength | ≥MPa | 15.0 | 15.0 | 14.0 | 14.0 |

Elongation at Break | ≥ % | 180 | 180 | 150 | 150 |

Impact Brittleness Temperature | ℃ | -25 | -15 | -15 | -8 |

Volume Resistivity, at 20℃ | ≥Ω.m | 1.0×108 | 1.0×108 | 1.0×109 | 1.0×109 |

Dielectric Strength | ≥MV/m | 18 | 18 | 18 | 18 |

Hot Deformation | ≤ % | 50 | 50 | 50 | 50 |

Thermal Stability Time at 200℃ | ≥ min | 50 | 60 | 80 | 80 |

Oxygen Index | ≥ % | 32 | 36 | 40 | 48 |

Thermal Aging |

|

|

|

|

|

Aging Temperature | ℃ | 100±2 | 100±2 | 100±1 | 100±1 |

Aging Time | h | 168 | 168 | 240 | 240 |

Tensile Strength after aging | ≥MPa | 15.0 | 15.0 | - | - |

Variation on Tensile Strength | % | ±20 | ±20 | ≥+85% | ≥+85% |

Elongation at Break after aging | ≥ % | 180 | 180 | - | - |

Variation on Elongation at Break | % | ±20 | ±20 | ≥+70% | ≥+70% |

Loss of Mass | ≤ g/m2 | 23 | 23 | - | - |

- Q: How long do olive nets typically last?

- Olive nets typically last for several years with proper care and maintenance.

- Q: Do olive nets affect the taste or quality of olives?

- Yes, olive nets can affect the taste and quality of olives. Olive nets are used to prevent olives from falling to the ground during harvest, protecting them from damage. However, if left on for too long, the nets can restrict airflow and sunlight, leading to increased moisture and potential fungal growth. This can negatively impact the taste and quality of the olives. Therefore, it is important to use olive nets judiciously and remove them after the harvest period.

- Q: Advantages of plastic furniture

- Colorful plastic furniture lines smooth bright color, in addition to the common white, red orange yellow green blue purple...... There are all kinds of colors, and there are transparent furniture, and its bright visual effects bring people visual comfort. At the same time, because the plastic furniture is made by the mold forming, so it has remarkable characteristics of smooth lines, each round, each arc, each grid and the interface are natural and smooth, without manual traces.

- Q: Can olive nets be used in hilly or sloped orchards?

- Yes, olive nets can be used in hilly or sloped orchards. The nets can be installed on terraces or slopes to protect the olives from falling off the trees and to facilitate harvesting.

- Q: Are there any specific techniques for training olive tree branches when using olive nets?

- Yes, there are specific techniques for training olive tree branches when using olive nets. One common technique is called "hedging and topping," where the branches are pruned to maintain a specific height and shape that facilitates the use of olive nets. This helps in ensuring that the net can be easily placed and removed without damaging the branches or the tree. Additionally, some olive farmers also use techniques like tying or staking the branches to keep them in a desired position while the nets are in place. Overall, careful pruning and strategic branch management are crucial for effective training when using olive nets.

- Q: How do olive nets prevent olives from bruising?

- Olive nets prevent olives from bruising by providing a protective layer between the olives and the ground. The nets catch the falling olives, preventing them from hitting the hard surface and getting damaged. This way, the olives remain intact and free from bruising during the harvesting process.

- Q: How do olive nets prevent damage from heavy machinery during harvesting?

- Olive nets act as a protective barrier between the heavy machinery and the olive trees, preventing direct contact and potential damage. The nets are spread out under the tree canopy, catching the falling olives and creating a soft landing surface for the machinery. This helps to minimize the impact and pressure that the machinery exerts on the ground and tree roots, reducing the risk of root damage, soil compaction, and overall harm to the olive trees.

- Q: What is the average lifespan of an olive tree?

- The average lifespan of an olive tree is typically between 500 to 600 years.

- Q: Are there any specific techniques for removing olive nets after harvesting?

- Yes, there are specific techniques for removing olive nets after harvesting. One common method is to carefully lift the nets from one end, allowing the olives to roll off into a collection container or onto a tarp. Another approach is to gently shake the nets to dislodge the olives, ensuring they fall onto a clean surface. Additionally, some farmers use mechanical devices or tools designed specifically for removing olives from the nets. It is important to handle the nets with care to minimize damage and preserve their longevity for future use.

- Q: What are the advantages and disadvantages of plastic wallpaper?

- Superior performance, the use of plastic wallpaper, if the underlying structures such as walls, roof surface also does not affect the use of a crack, it has good scalability and high tensile strength, in addition, can also according to the plastic wallpaper with flame retardant, anti mildew, sound absorption, bio products and other functions need to be processed.

Send your message to us

High Flame retardant PVC jacket compound

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 3000 Tons kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords