Gypsum ceiling tiles interior ceiling packaging

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 126000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

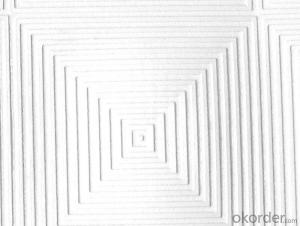

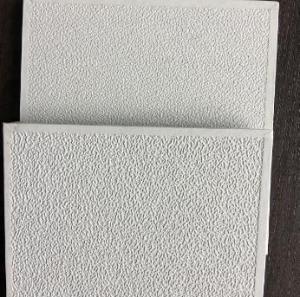

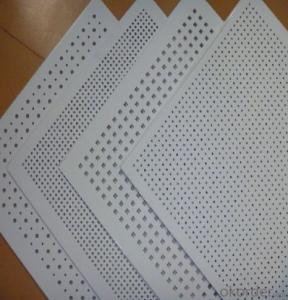

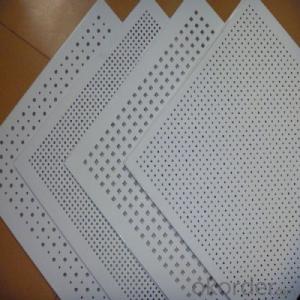

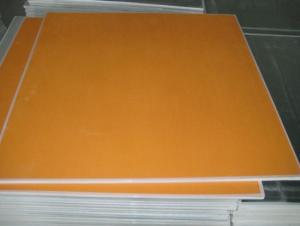

Gypsum ceiling tiles interior ceiling packaging is made of an incombustible gypsum. The regular gypsum ceiling tiles which contains gypsum plaster - a high quality product that is free of any harmful substances, that fulfils all current international requirements.

The ceiling tiles are laminated with anti static PVC film on the front side and aluminum pet foil on the back side which gives the tiles superior, maintenance, free finish along with additional thermal insulation properties. It can be used in areas requiring clean, dust-free interior such as computer rooms, food processing electronics and pharmaceutical companies.

Face : textured washable vinyl(PVC)

Back: aluminum foil backing

Available thickness : from 7mm to 12mm

Available size : (customized sizes are also available)

595x595mm / 595x1195mm

603x603mm / 603x1213mm

605x605mm / 605x1215mm

617x617mm / 617x1243mm

Loading Capacity for Gypsum Ceiling:

STANDARD SIZE | THICKNESS / (mm ) | PACKAGING | QUANTITY / M2 /1X20FCL |

595*595mm; 603*603mm | 7 mm | 10 PCS / CTN | 4200 M2 |

595*595mm; 603*603mm | 8mm | 10 PCS / CTN | 3700 M2 |

595*595mm; 603*603mm | 9 mm | 10 PCS / CTN | 3300 M2 |

595*595mm; 603*603mm | 10mm | 8 PCS / CTN | 2700 M2 |

595*595mm; 603*603mm | 12 mm | 8 PCS / CTN | 2500 M2

|

Application:

They are widely used in all commercial and institutional buildings such as offices, hospitals, schools, restaurants and shops.

Gypsum ceiling tiles interior ceiling packaging

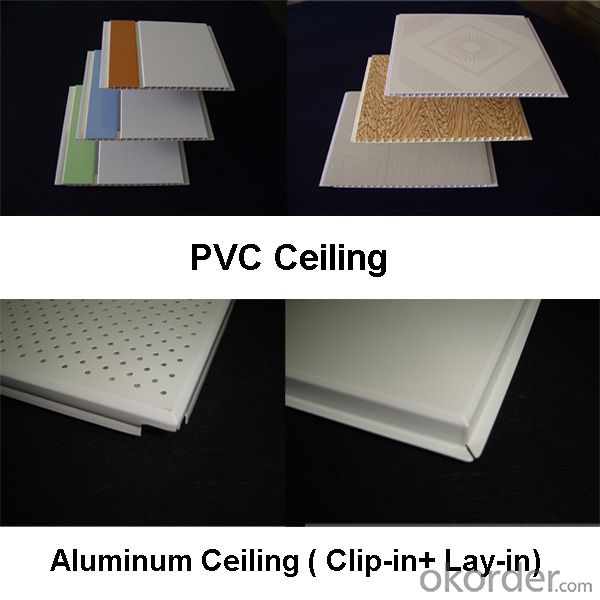

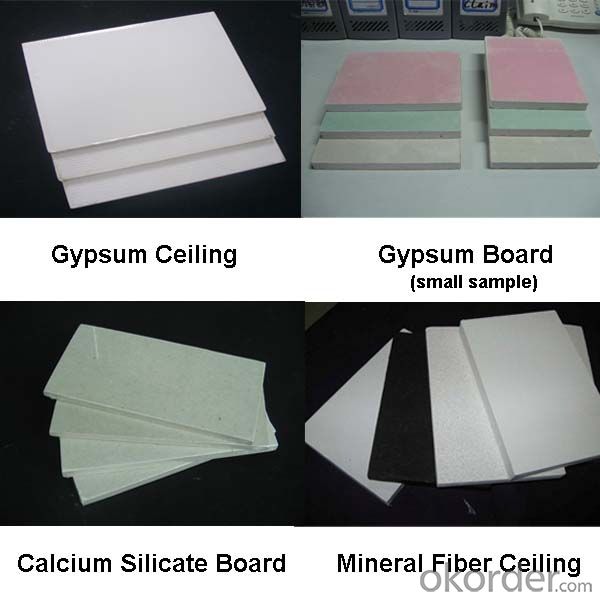

Other products we supply:

- Q: Ceiling ceiling installation of the problem?

- 1,The strength of calcium silicate board is stronger than that of gypsum board in general, and the bearing force is not a problem, and it can meet the requirements of your ceiling lamp. 2. The installation of lamps must wait until the latex paint all the construction after the line, if the first installed lights, after the paint will be dirty lights, and the construction of paint is very troublesome, easy to leak the area brush less than the paint. 3. generally will not affect the seams, installed lights workers in the construction time will first look for wood position, will not affect the seams. 4 gypsum line do not have to fight nails, the use of gypsum sticky powder stick to the very strong, there is no need to nail again.

- Q: Gypsum ceiling broken a good hole repair it? How much money is needed

- A: rotten hole processing flat, with two long 45 cm (must be greater than the hole) of the wood keel, the wooden keel even nail in the gypsum board to be used to fill holes. Two: the board on the hole, and then fixed, gypsum powder Phi seam. Paste the tape, putty putty. Dry sandpaper polished, and then brush latex paint.

- Q: Because I want to change part of the circuit Want to split some living room ceiling The original installed gypsum board ceiling can be demolished? Is it possible to replace it later?

- Can be demolished, but a demolition will demolition of a whole! Can not guarantee that you do not break when the bad Oh. Must buy a new re-installed up.

- Q: Gypsum board ceiling practice

- (1) Check the installation of the roof concealed works, such as air conditioning system, fire spray, smoke system, supply, power distribution system, background music and other lines are installed in place and the hidden acceptance. (2) according to the design requirements around the leveling, the middle of the shed from the conventional arch (3) the boom can be used to cast the board when the embedded parts or reserved hook connection, can also be used offset screws, fixed in the upstairs after drilling (4) boom keel spacing by the manufacturers to provide a reasonable distribution of materials, keel connection to be fixed after the line leveling. (5) all metal parts such as no electroplating, must first brush rust oil twice (6) the edge of the gypsum board planed into a chamfer, and then with a tapping screw and keel compound, tighten. (7) gypsum board docking slit 2-3mm, and chamfer, covered with caulking putty, the joint belt buried in the putty, and putty to the gypsum board chamfer filled, after the plate with a flat plate leveling The

- Q: Use gypsum board to do the ceiling, the general life of how long, I always feel inside the rust after the wire will fall, there is no one professional know?

- Gypsum board ceilings generally do not drop to; national standards; as follows: According to the normal distribution of hanging a general 1 square meter, diameter 6mm-10mm; main keel spacing 300mm-600mm; Gypsum board and keel connection is self-tapping screws, generally 200mm a fixed; The project is not in this row;

- Q: What material to do with the ceiling

- If it is residential I recommend using gypsum and wooden side. Both convenient construction and beautiful environmental protection. But the toilet or use pvc Come, you can moisture.

- Q: Can the living room ceiling be covered with an aluminum cords? How is the effect?

- Living room ceiling is not recommended with aluminum slab ceiling, aluminum slab ceiling is generally used for kitchen and bathroom, it is recommended that you use gypsum board ceiling is better. Plasterboard ceiling with the following advantages: Gypsum board is based on plaster as the main raw material mixed with additives made of fiber, with light, adiabatic, sound absorption, non-combustible and sawable and other properties. Used for commercial space, the general use of 600x600mm (the project did not specify the length of the unit, the units are mm) specifications, there are bone and bones of the points. Keel commonly used aluminum or iron. Gypsum board ceiling is mainly reflected in his fire, noise, heat, light, high strength, low shrinkage and other characteristics, and its stability is good, not aging, it will not be insects, and construction comparison Convenient, it can be nail nails, you can also use the saw, you can also use the planing method, sticky series of methods of construction. Mainly used in the ceiling, partitions, interior walls, panels and so on. The Slate ceiling price comparison, and easy to modify, demolition and other advantages. In addition, the gypsum board ceiling than the aluminum cords hanging ceiling more beautiful, you can do a variety of shapes, not like aluminum hanging plate ceiling as cold, monotonous!

- Q: Ordinary interior decoration ceiling per square price

- Depends on what you asked, and so on, ranging from 50 to 100.

- Q: i did some false celing "gypsum board" design and im still confused with what painting color shall i paint them .. my furniture color is Maroon (Dark and Light) and Beige ..P.S. here im talking about the Salon and Dining Room .. the color of the walls is Ivory "i guess :S" but all i need to know is what color shall i paint the Gyps ... Does Light Peach go with it?! or what other color would u recommend .. pls help me take a good decision ... its a new apartment by the way so i want it to look pretty :DThx u

- Ceilings are best painted white with a ceiling paint. Ceiling paint is thicker so it won't drip. paint-and-supplies.hardwarestore....

- Q: What kind of material is the interior of the ceiling?

- Indoor ceiling lines close a lot of material. More common are: gypsum lines, solid wood lines, high-density bubble line, stainless steel lines, glass lines, etc. This line can be arbitrarily modified processing, different materials can be made not the same effect.

Send your message to us

Gypsum ceiling tiles interior ceiling packaging

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 126000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords