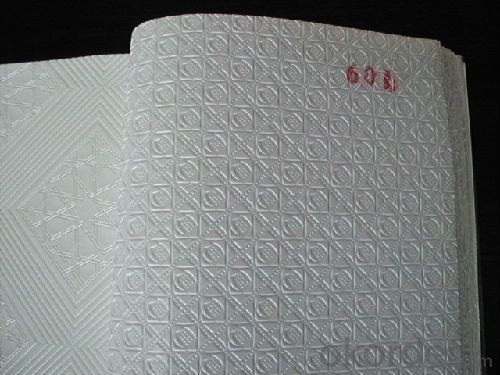

Gypsum Ceiling Through a High Technological Manufacturing Process

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 4000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Applications:

This material is mainly used in the indoor decoration of super class buildings such as hotels, restaurants, shopping malls theaters, danceries, cinemas, stations,auditoriums, offices, sitting rooms, business buildings, electronic workshops,precision apparatus rooms and industrial or residential buildings. We have 5 series of products:Painting relievo surface Printing pellicle surfaceSuperior pellicle surface Clean non-dust surfaceAdvanced pellicle backside aluminum foil surface.

Product Advantages:

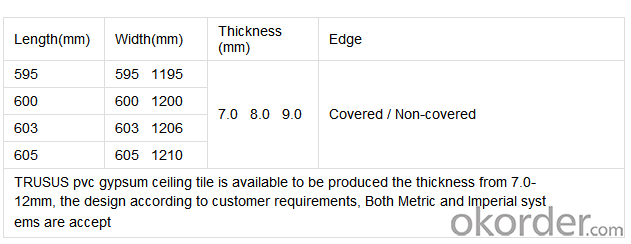

1) Material: Germany KNAUF paper-faced gypsum board

2) Thickness: 7mm-15mm

4) Weight: 7kg/sqm

5) Strength: >160N

6) Characters: non-flammable B1, in accordance with Chinese standard GB8624-1997

7) Installation: match with ceiling T-bar.

Packing:standard marine package, by wood pallet or in bulk

Product Specifications:

Images:

- Q: Gypsum board ceiling hanging good, can cut off part?

- You can use the integrated ceiling, with Jane Europe's style to do, with a few lights, not ugly. Kitchen restaurant integration. The The Or is it recommended to isolate the kitchen fumes too large in the living room and the restaurant's ceiling or

- Q: Our family is 2 meters high 6, the ceiling is also used to do? How high is it?

- You can use the type of aluminum buckle board ah, simple and does not take up space, as far as possible not too bright color

- Q: Gypsum board two faces which face up to install the ceiling

- Seal processing (1) modulation of one-component caulking plaster putty The container used for modulation must be clean. According to the provisions of the proportion of the first clean water will be poured into the container, and then slowly to the water cast gypsum powder, let it swell 5min, and then stir the stir bar into a slurry without caking thick slurry, Modulation of a good pulp, can no longer add gypsum powder, so as not to agglomerate. Generally applicable to the construction time of 45min, more than time to start solidification, can not be used. (2) Board edge treatment The edge of the sheet is not treated, and the cut edge of the board should be treated as follows: Before the board is installed, gently press the front edge of the cardboard side and then use the knife Chamfer the side of the paper to pick the upper layer, and pick the open face paper torn, pay attention to the gypsum core can not be exposed, this part still keep the paper under the paper. (3) capping process With a small scraper will be stitched putty evenly embedded in the lower part of the gap between the joints, so putty squeeze the back panel side, to form a protruding putty along the mouth, so that the edge of the board with the stopper putty more firmly. Until the putty completely dry, with electric or manual sander, No. 2 emery will be slit plaster putty polished. And then with the entire paper gypsum ceiling decoration construction.

- Q: Living room aisle hit a few rectangular frame, suitable to install what light?

- Gypsum line: Gypsum line is the decoration of the house, the main interior decoration. Can bring a variety of patterns practical and beautiful. With fire, moisture, insulation, noise, heat insulation, and can play a luxurious decorative effect.

- Q: Decorative light steel keel how many flat for an inspection lot

- The same variety of ceiling works every 50 (large area rooms and corridors by ceiling area of 30m2 for a) should be divided into a inspection lot, less than 50 divided into a inspection lot. According to each level or each layer of construction (or deformation of the seam) as a test batch, high-rise building standard layer for every three (less than 3 layers by 3 layers) as a test batch. Before the construction and supervision units together with the inspection lot, determine the number of inspection batch.

- Q: Ward to the top how to paste plaster line

- First in the top of the closet ceiling 10cm (the thickness and your vertex line thickness consistent), and then in the ceiling side plus the top angle, wardrobe is equal to 10 cm short, but does not damage the effect of the top angle.

- Q: Gypsum of the ceiling appeared a big hole, how to repair

- You find a special understanding to ask it, but also how to do it

- Q: Is it glued up? What is the glue used?

- Check the quality of gypsum wire and use the surface of the high quality gypsum line to install. You can use glue to speed up the sticky powder paste gypsum line to the carrier. Forced to hold the gypsum line a minute or two, the squeeze out of the glue in a clear gap position.

- Q: Gypsum board ceiling thickness generally how much

- Gypsum board is now the market is the most commonly used thickness of 8.5mm, 9.0mm are generally less than 9 thick, there is 9.5mm, the choice of brand a little better,

- Q: Can the living room ceiling be covered with an aluminum cords? How is the effect?

- At present, kitchen and toilet ceiling generally use aluminum plate, of course, the living room can be. But relatively speaking, it is expensive. As for the effect, or very good.

Send your message to us

Gypsum Ceiling Through a High Technological Manufacturing Process

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 4000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords