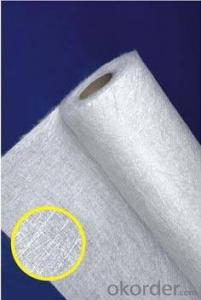

Glass Fiber Chopped Strand Mat/Fiberglass Mat/Emulsion or Powder Mat

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 44 roll

- Supply Capability:

- 100000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Introduce

Surfacing Veil is mainly used in the surface layers of FRP products.It is divided into winding

mainly used on pipe and tank winding process.It can improve the product

surface property on corrosion resistance, compressive strength, seepage resistance, and

longer service life.

chiefly used in the product with complicated geometric curve. It has the advantages

of good pattern fitness,quick resin permeation.It can raise the intensity and corrosion

resistance of products.

Specifications:

Fiberglass Surfacing Tissue

ISO9001:2008 quality control

1.Uniform fiber dispersion

2.Smooth surface

Fast resin impregnation

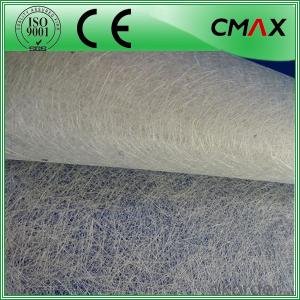

E Fiberglass Surfacing Mat (FRP surface tissue) is mainly used as the surface layers of FRP products. The surfacing tissues are applicable to FRP several moulding process, such as hand lay-up, press moulding spary-up, RTM, ect...

Applications:

1) Improve the performances of surface layer

It can significantly improve the performances of surface layer to realize longer lifetime and resistance against corrosion, leakage and compression.

2) Cover up the texture of underlayers

It is indispensable materials for high quality moulds and FRP products as it is capable of covering up the texture of underlayers to create high gloss surface that give rise to improved strength and corrosion resistance.

Product Characteristics:

1.Uniform fiber dispersion

2.Smooth surface and soft hand-feeling

3.Low binder content

4.Fast resin impregnation

5.Good mould obedience

6.Good corrosion resistance

7.Strong impact resistance

Product Feature

1 Excellent fiber distribution

2 Smooth surface appearance of finished products

3 Low binder content

4 Good molding properties

Package

Product is manufacture in form of a roll warp on a paper tube then after packed in a plastic bag and placed with in a cardboard .Carton. Rolls can be loaded in a container directly or on pallets.

Quantity(Fiberglass mat)

20’GP container: about 10000kgs

40’HC container :about 23100kgs

Technical Date

Picture

Package

workshop

FAQ

1.Q: What specification do you have for E glass Fiberglass chopped strand mat ?

A: Now our normal specification of fiberglass mat have 45/50/55/60/90/100gsm, can be customized.

2.Q:How about the width?

A:The normal width is 1000mm, can be customized.

3.Q:How about the sample delivery?

A.Small sample is free of charge, sample ready time 3-5days.

4.Q:How about the delivery time?

A:It is depend on the order quantity, three 20'ft container around 20days.

- Q: Waterproof materials related to the raw materials which ah

- Waterproof materials involved in the raw materials are: Asphalt waterproofing membrane main raw materials are: asphalt, sbs, apao, oil (oil three-line oil, rubber powder, recycled propylene, talc and so on. The main raw material of polymer waterproofing membrane is some olefins. The structure of the building to prevent the rain, snow and groundwater penetration; to prevent the air of moisture, steam and other harmful gases and liquid erosion; separation structure to prevent the infiltration of water supply and drainage. These impermeable, leaking and eroded materials are collectively referred to as waterproof materials.

Send your message to us

Glass Fiber Chopped Strand Mat/Fiberglass Mat/Emulsion or Powder Mat

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 44 roll

- Supply Capability:

- 100000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords