FRP Sheet Production Line with Great Price in China

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 26 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

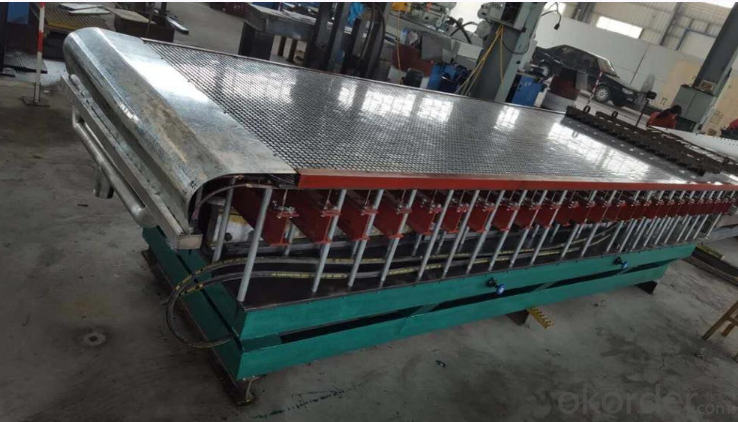

FRP Sheet Production Line with Great Price in China

Product Description:

This equipment can produce many kinds of sheets,and different colors.We can changing the molds to produce different type of sheet.Use to warehouse,factory,gardens,agricultural ect.

Product Features:

1.High strength,light weight

2.good designability.

3.Anti-fire,anti-water,anti-aging,anti-corrosive

4.Enviromental protection

Product parameter:

Name | FRP Sheet Production Line with Great Price in China |

Brand | CMAX |

Weight | 10-20T |

Dimension(L*W*H) | BASED |

Power | 15KW |

Voltage | 380V /220V |

Product Type | FRP Machinery |

Certification | ISO9001:2008 |

Appilication | Sheet |

Raw material | Fiber Reinforced Plastic |

Place of Origin | Beijing, China (Mainland) |

Color | Selectable |

Warranty | 12 Months |

Time of Delivery | 30-45 days |

Product Pictures:

Our Service:

1.Guarantee for 12 Months excluding wear electrical parts.Extra fee is paid if out of date.

2.Any damage to the machine caused by improper use will be charged.

3.The equiment is fully test before dilivery.

4.Free installation tarining and commissioning on site to help the operator operate as soon as possible.

5.We will provide wear and electrical parts at an agency price when you need replacement.

FAQ:

1.How can you ensure your quality?

First, welcome to visit us. After your vision in our factory , envionment and work team, you can judge by yourself.

Second, according to your request, we can provide the same sample for you to confirm.

Third, We have inspectional department.

2. Can we visit your company?

Welcome. We hope you and your team come to our company.

3.Can you provide sample ?

Yes, we can provide sample and it's free. You only charge the freight fee, and we will return the freight fee if you set the order.

- Q: I need to know where to buy the equipment and what I need to do

- PVC fiber reinforced hose machine is suitable for the plastic flexible pipe, provide first-class service characteristics of pressure liquid conveying water Henan Anyang HuaSu Machinery Manufacturing Co. Ltd. fly for you: the best quality, best price. High output and low power consumption

- Q: Does anyone know any machine for processing plastic products?.

- The injection molding machine, blow molding, rotational molding, thermosetting squeeze a lot

- Q: this month bought a 180 thousand of the equipment and issued a value-added tax invoices, this sum of money can be deducted? How much deduction?Previously fixed assets are not deductible? Is this a policy that has just been changed this year? What's the tax rate? Thank you!

- Can be deducted from the value-added tax invoices on value-added tax deductible, in addition to the purchase of equipment costs, if there are qualified transport documents, you can also by freight * 7% deduction of input tax

- Q: Is it gear oil or general oil?Inside the old oil is relatively thin, the new gear oil is relatively thick. Can you add?.Please point out.Should we add "ordinary gear oil" or "hyperbolic"?

- Gear oil should be added, and the old one may be flooded or originally not gear oil.Regular is ok.

- Q: What are the standard tolerances for engineering plastic products machined (e.g. lathes, milling machines)?

- No, look at the drawings, requirements, no note tolerances, drawings should be marked, and if there is no mark, then there is a problem with drawings. Drawing requires that all elements be annotated.

- Q: I am going to work as a worker in a plastics factory. I wonder if the work inside it is very polluting. Is there any harm to the health?

- Plastic is basically non-toxic, but there are several special raw materials, heating will produce toxic gases, but little harm.

- Q: The difference between plasticization and processability of plastics in extrusion process

- I. Introduction of extruderIn the screw extruder is under the action of the molten plastic extrusion through fixed shape extrusion, water cooling after cutting in the traction machine under the same section is mainly used for a variety of products. A large number of continuous production, such as tube, rod, profile, also can be used for plastic modification and granulation. The basic mechanism of extrusion is very simple a screw in the cylinder to rotate and move forward the plastic. The screw is actually a ramp or slope that is wound around the center layer. The aim is to increase the pressure to overcome the greater resistance. Is an extruder, there are 3 kinds of resistance to overcome: solid particles (feed) on the cylinder wall friction and screw rotation before laps (feed) the mutual friction between them; melt in the cylinder wall adhesion; melt pushed forward when the resistance of the internal logistics.

- Q: where there are advanced environment-friendly recycled plastic processing equipment?

- Environmental protection recycling plant, this is a systematic project, the use of granulation machine is usually used granulator, need to be matched with waste water filtration, sedimentation, purification treatment pond, waste gas purification equipment.

- Q: What kind of equipment do you need for the food market? How much would you like to invest? What about the profit?

- if 2 more than 20000 more than 20000 color printing, bag making machine semi-automatic, fully automatic ranging from 4-5 million, 3500 mill more than 20000, granulator, raw materials are polyethylene, if the price of raw materials is a new material price 11000 tons, if it is recycled about 7000 of us production of complete sets of equipment

- Q: What mechanical products do you use to make this plastic product?! The more detailed, the better!

- I'm not sure about the mold design. You can find a device and ask for advice. Generally, they will be responsible for design and training

Send your message to us

FRP Sheet Production Line with Great Price in China

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 26 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches