FRP Pultrusion Machine and Production Line in High Quality with high quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 set

- Supply Capability:

- 27 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

FRP Pultrusion Machine and Production Line in High Quality with high quality

Product Description:

Pultrusion process is put the impregnation fiberglass.yarn,mat and other strength material,from the traction to through the mould heating,pultrusion,curing,then continuous to produce into the difference products.

Product Features:

1.The production process is continuous,and the produce quality is stable,good repeatability

2.There can according to the requirement to adjust the content of strength material,high strength.

3.It can produce the complex shape product,can meet the special site use requirement.

4.The product have good integrality,high useful for raw material.

5.The equipment cost is low.

Product Parameter:

Name | FRP Pultrusion Machine and Production Line in High Quality with high quality |

Brand | CMAX |

Weight | 2-7T |

Dimension(L*W*H) | 21mx2.8mx1.2m |

Power | 50KW |

Voltage | 440V/220V |

Product Type | FRP Machinery |

Certification | ISO9001:2008 |

Appilication | Granules |

Raw material | Fiber Reinforced Plastic |

Place of Origin | Beijing, China (Mainland) |

Color | Customized |

Warranty | 1 Year |

Time of Delivery | 30-45 days |

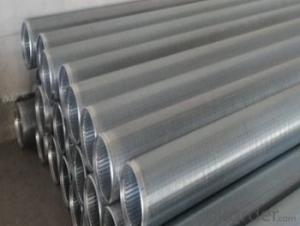

Product Pictures:

FAQ:

Q1:How Can I Get A Sample?

A1:You can get samples by communicate with our export sales.

Q2:How Long Is Delivery?

A2:Delivery time will be30-45days according to order quantity.

Q3:What Is The MOQ?

A3:MOQ depends on different items.

- Q: PPO plastic mold commonly used steel processing?

- Application range6 polyphenylene ether is high strength engineering plastics development 60s of this century, it has high mechanical strength and creep resistance; excellent electrical properties, high temperature to 120 DEG C, and in a wide temperature range, stable size, mechanical properties and electrical properties change little; absorption of water vapor is very small. Cooking. Widely used in electronic, electrical components, medical equipment, cameras and office equipment, and so onCommon problem7 injection molding process characteristics and process parameters of modified polyphenylene oxidePolyphenylene oxide (also known as: polyphenylene oxide) [PPO] has good chemical stability, low creep, aging resistance, and it is not easy to burn. Because of its good water resistance, polyphenylene oxide is widely used as an engineering plastic.The major disadvantages of polyphenylene oxide are: poor flowability of melt, difficulty in forming process, tendency of cross linking, expensive price, easy stress cracking and unstable impact strength.

- Q: What are the methods of forming plastic products introduced in this course?

- Commonly used molding methods have the following1, rolling formingCalendering is often used in thermoplastics. It is used to deliver plastic to a number of parallel, counter rotating hot rollers, which are rolled over many times2, tape castingCasting with dry plastic. It is soluble in the solvent of plastic, due to weight andspread to continuous operation of the metal belt, become thin layer of uniform thickness, then heating apparatus soft volatile agent, curing products, production of film or sheet.3, extrusion moldingExtrusion molding is often used in thermoplastics. This is a melt plasticized plastic which is extruded from the die cavity of the die at the head of the extruder and forms a profile similar to that of the die. It produces plates, pipes, bars, wires, profiles and so on

- Q: What are the features of plastic injection gears and machined plastic gears?

- Injection of better, smooth finish, smoothness can be done on the mold, the strength is also good. When machining, some of the transmission, the edge may be very difficult to process, very beautiful

- Q: Which plastic is suitable for processing 3mm threaded holes and is best resistant to corrosion?

- Nylon processing generally efficiency is relatively high, tool wear is relatively small.

- Q: profit is not big, about how much investment, please expert advice, mainly to supply the market and small supermarkets

- I just do this, the raw material is used PE, equipment, there are mainly blowing machine, punching machine, if you want to print, then also the printing press, there are other stirring what ah!

- Q: I haven't done it before, and I don't know how to do it Would you please tell me how to do this? How to do it? Good to do

- Good to do, there is money, what is good to do, grasp the source of raw materials ah, finished marketing ah!

- Q: Would like to ask a few questions?1, waste plastics need to go through a few devices or steps to become plastic particles2, how much would it cost for the whole set of plastic particles? (I want to get a small wire first)3, if the equipment, plastic material can be any processing?4, is there any pollution in the whole process?.5, how about this prospect this year?Please have experienced predecessors to give some experience

- 3: not for any polypropylene and Juyi plastic processing should be able to use other plastic should not4: the cleaning of this piece in processing will cause two pollution5: This is mainly to see you personally, as the saying goes, peers are different, in general, the plastics industry is OK

- Q: One hundredUrgently!!!Find a kind of plastic that can be used for machining. The better the machining performance, the cheaper the better.Used for the principle model, in the past, when the school practice, used a milky white opaque material, feel good, but I do not know what the name.Copy paste party, do not come to a great God level, experienced best. Kneel thanks!Can PVC be used for machining? As long as you can get on the lathe. If there is a better buy channels.To pipe, diameter 20,40, 65mm 1 each. The lengths are 450450335mm.Can PMMA (acrylic) stick be machined? The supervisor told me that nylon rods do not work and that moisture size is not guaranteed.Then suggest I use this... Which is better than PVC? Thank you

- PSU plastic, this plastic can be machined. The factory where I practiced has used detailed parameters. You can check it online

- Q: What kind of units do you need to process plastic injection products?I own the business, there are plastic injection molding machine more than, can produce all kinds of plastic products, order ~ unit in Hangzhou ~!

- It's easy to come out of the classified trade ads in the newspaper magazines in Hangzhou

- Q: tooling mold design, processing, whether the need for quality certification system?

- Management system certification is basically looking at the enterprise's own needs, nor is it mandatory, but if you are here, if useful in the car, you have to do TS certification

Send your message to us

FRP Pultrusion Machine and Production Line in High Quality with high quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 set

- Supply Capability:

- 27 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches