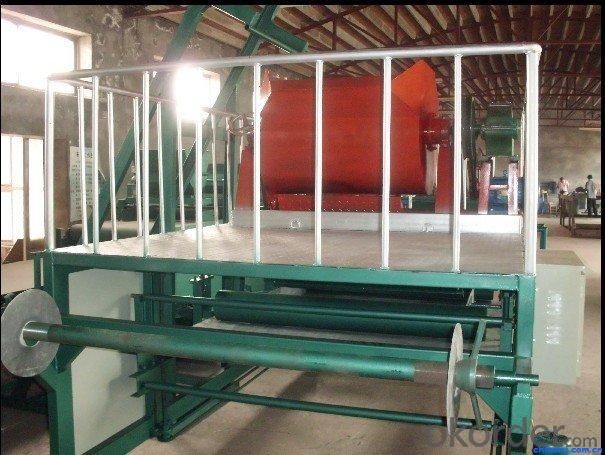

FRP Manhole Cover Making Machine and Moulding Compound Machine

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 set

- Supply Capability:

- 26 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

FRP Description:

FRP grating made from different production process, FRP grating can be divided into two types: Molded grating and Pultrusion grating.Our molded fiberglass gratings and Pultrusion fiberglass gratings provide unmatched corrosion resistance properties, especially when compared to other metal flooring products. Strength, long life and safety are also superior qualities of our fiberglass grating products, and their electrically non-conductive properties make them the ideal option.

Product Features:

1. Easy operation based on PLC intellectual control system. Only short-term training can make operators complete production independently.

2. Unique arithmetic on temperature control makes oven heating fast, temperature control precise. Which improve quality of products, reduce energy consumption and shorten the preparing time effectively.

3. Roving chopper speed can be synchronous with the production line.

4. Special cross cutting machine and good synchronization performance make cutting accurately.

Product Advantages:

1) Convenient and reliable installation, low construction expenses

2) Excellent heat-insulation property from minimum thermal conductivity

3) Light weight, convenient to transport and handle, good for labor-saving.

4) Smooth inner walls reduce pressure loss and increase flow speed

5) Excellent design ensure suitability for both exposed and hidden installation

6) Recyclable, environment-friendly, accords with GBM standards

Product Parameter:

Name | FRP Manhole Cover Making Machine and Moulding Compound Machine |

Brand | CMAX |

Weight | 8T |

Dimension(L*W*H) | 900x660 X1700 |

Power | 37KW |

Voltage | 380V 50HZ |

Type | Pipe Production Line |

Certification | ISO9001 |

Appilication | Pipe |

Raw material | PE |

Place of Origin | Hebei, China (Mainland) |

Color | Customized |

Product Pictures:

FAQ:

Q1:How Can I Get A Sample?

A1:You can get samples by communicate with our export sales.

Q2:How Long Is Delivery?

A2:Delivery time will be 30-45 days according to order quantity.

Q3:What Is The MOQ?

A3:MOQ depends on different items.

- Q: Which kind of engineering plastics can be machined on machine tools?

- General raw materials market is available, you can also contact the internet.

- Q: I am engaged in the plastic processing industry, mainly for ABS and PP through chemical agent for processing, will this be harmful to the body?

- Alkyl tea sulfonate (ABS) can not only poison the body, but also promote carcinogenic effects of carcinogens. Recently, it has been found that ABS also has the risk of teratogenic changes.Polypropylene (PP) itself is non-toxic, but I do not know what you say powder ingredients, if there are plasticizers, masterbatch and the like, there is a certain toxicity.In the production of ABS containing detergent factory, should pay attention to do a good job of environmental protection, adopt cleaner type production process, in the production process to be closed, to reduce the concentration of ABS in the air of workplace and workers to do protective measures.

- Q: How much does it cost to process disposable plastic bags?

- The package of blow molding machine, cutting machine, switchboard, mixing machine totaling about 120 thousand

- Q: What do you understand in the early stage and how much equipment are needed for the preparation?. Thank you

- Then don't do it. Baidu can't support you in such a big deal. Because big bosses rarely disclose business experience on Baidu - find a reliable master or technician and learn from it

- Q: Do waste plastics recycling processing, the state subsidies, and now the prospects are good?

- Moreover, the after-sale service of the manufacturer is very good. So it works very well. I recommend you to Shandong Qufu (Confucius's hometown) to look at the side of field visit, actually there's a purchase as clear as noonday, Shengxin machinery Bao Aiqing is the manager of a professional, give you a ball 897026688 and ask what questions or ask professional better.

- Q: I did not come into contact with the plastic design, to understand the mechanical design and traditional design of plastic parts and fittings of the (metal material) are different, from what kind of material, design, drawing standards, labeling etc.. Please engage in plastic design industry heroes pointing!

- Different materials of plastic properties vary greatly, to take into account the relatively soft plastic, high shrinkage, not good to step up, fine machining difficult. There is no obvious difference between the drawings, mainly because of the different processing techniques.

- Q: now have no market quite suck me how to go find the market ask predecessors and friends hope that they can point out a way to thank you

- I'm from Guilin, Guangxi.I'm a commodity trading company. How many styles do you have?

- Q: I haven't done it before, and I don't know how to do it Would you please tell me how to do this? How to do it? Good to do

- Good to do, there is money, what is good to do, grasp the source of raw materials ah, finished marketing ah!

- Q: I don't know how much money it needs! Raw materials are used plastic baskets!

- Production of this material, a basic set of machinery and equipment investment of about 70 thousand, if the amount of large, you can choose to configure the machine at around 200 thousand.

- Q: Plastic PS with ABS and other mixed processing?

- OPP: oriented polypropylene (film)PP: PolypropyleneIt's a semi crystalline thermoplastic. With high impact resistance, strong mechanical properties, resistance to a variety of organic solvents and acid base corrosion. It is widely used in industry and is one of the common polymer materials. Australian coins are also made from polypropylene

Send your message to us

FRP Manhole Cover Making Machine and Moulding Compound Machine

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 set

- Supply Capability:

- 26 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords