FRP Grating Moulded Machine Manufacture Light Weight of Different Styles

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 21 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

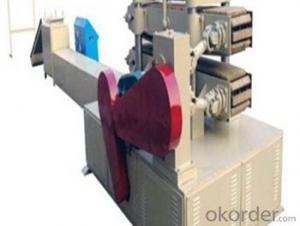

FRP Grating Moulded Machine Manufacture Light Weight of Different Styles

Product Description:

Molded grating is manufactured by laying continuous glass fibres in the mould in the direction of vertical and horizontal, and thoroughly wetted out with resin, layer by layer. When the weaving process is completed, the mould is heated to cure the panel. After curing, the panel is ejected from the mould. The standard panel would have meniscus(concave) top surface. Any process such as post applied grit could be bonded after as a secondary operation.

Product Features:

High anti-fire, High anti-corrosion and anti-aging, High anti-slippery, Light,but high loaded strength, Long service life and maintenance free, Non-conduction or magnetic, Easy installation and rich colors, Various sizes and colors available.

Product Parameter:

Name | FRP Grating Moulded Machine Manufacture Light Weight of Different Styles |

Brand | CMAX |

Weight | 4-8T |

Dimension(L*W*H) | Machine Model |

Power | 35-65KW |

Voltage | 380V 50HZ 3Phase(Customized) |

Product Type | FRP Machinery |

Certification | ISO9001:2008 |

Application | Profile |

Raw material | Fiber Reinforced Plastic |

Place of Origin | Hebei, China (Mainland) |

Color | Selectable |

Warranty | One Year |

Time of Delivery | 20-45 days |

Product Pictures:

Our Services:

1.Do free installation and trial run of microcomputer and equipment, do free training on operators, provide productdesign software until personnel from your honorable company skillfully master it.

2. Responsible for providing advanced domestic production techniques and providing matching techniques and equipment at any time following with development of production technology.

3. Within one year for all occurred troubles of the equipment we serve for you at any time to timely solve the troubles.

4. According to the regulations in the contract timely provide wearing parts in production line and equipment software data.

5. Assist you honorable company to do equipment reform or time changing work, assist you with upgrade work of the production line.

FAQ:

Q: Are you Trading Company or Manufacturing Factory?

A: We are both trading company and manufacturer. We have our own factory, welcome to send your inquiry!

Q: I am interested in your products, could I get sample for free?

A: We can supply a few pieces FREE samples if we have some in stock, and you only need to pay the freight cost by yourself. Welcome to send your inquiry for FREE samples!

Q: How about the Delivery time?

A: 20-45days after receiving the deposit.Welcome to ask for the detailed delivery time according to your order quantity!

Q: How can you guarantee the product quality?

A: We have the quality control system ISO9001:2008, and it's been followed strictly. and each our package worker will be in charge of the final inspection.

- Q: What are the methods of forming plastic products introduced in this course?

- 6 、 heating moldingHeat - forming thermoplastics are used to heat the plastic sheet into an elastic state and then press it to form a mold attached to the mold. Production of dishware, disc type products.7, foaming moldingThe foaming molding adds the foaming agent to the foam, then the foam is injected into the mold and is solidified into a product. The utility model is used for making cushioning packages for precise instruments and meters.8, moldingMolding for thermosetting plastics. This is a powder, flake or granular thermosetting resins and additives, directly close mold in mold, heating, pressurizing, plastic and liquefaction, chemical reaction and curing, cooling after the products. Producing plates and electrical appliances, machinery parts,9, casting jade moldingCast molding for thermosetting plastics. The molding powder into the barrel heating to heat plasticizing, pressed into the mold, and the product complete solidification under pressure. Complex products production needs to block metal objects.10, casting moldingCast molding is used to heat resistant plastics. It is a thermosetting plastic that is plasticized and injected into the mold. It is cured at atmospheric pressure, cooled and released

- Q: What are the standard tolerances for engineering plastic products machined (e.g. lathes, milling machines)?

- No, look at the drawings, requirements, no note tolerances, drawings should be marked, and if there is no mark, then there is a problem with drawings. Drawing requires that all elements be annotated.

- Q: Plastic POM POM generally used for the production of what plastic products?

- Fire regulating ring, support member, gear, rack, rubber wheel, remote control switch bracket, cam pressure bar, cosmetic container, toy car runner, mobile phone chute

- Q: Such as title, small items, but also the size of the palm, and want to mass production, plastic, production machinery, abrasives about how much money, the smallest sizeIn addition, the production of plastic products are not required sewage ah, online and other great god!!

- There are thousands of plastic, you first understand some commonly used bar, usually ABS, C material, B material. There are floating water and submerged, and so on. There are 4 kinds of plastic on a mineral water bottle, do you know?

- Q: What are the processes and machines used in the manufacture of plastic products?,

- Processing methods are: injection molding, extrusion, blow molding, blister and so on. Injection molding can be used to produce more complex shapes, such as TV housings. It is the plastic particles in the pre heating tube, and then through the screw under pressure, the melting of raw materials into the mold, cooling molding, the product has been made. Is prepared by continuous extrusion screw drive, which in the feed pipe (commonly known as the barrel) heating plasticization, and then squeeze the stereotypes in the mold, the desired shape, such as plastic buckle, pipes etc.. Blow molding and extrusion are somewhat similar, except that they are placed in compressed air to obtain shapes, such as plastic films, plastic bottles, etc.. Blister is relatively simple, it first made of plastic sheets, baking oven, and then placed in the mold, through the negative pressure to the sheet and mold close to the shape. The price of the equipment varies greatly according to the model and specifications, so it can be checked directly to the manufacturer.

- Q: What machines do you need? Where can I get the raw material? Thank you

- HelloThis kind of processing enterprises that currently need money also is not a small number, a factory operating the bowls and cups, from the general investment enterprise to calculate ten years for a period of time is a reasonable investment category, now, should be at least 600 thousand yuan of above, it should be said in in the village, such enterprises do not need too much liquidity, equipment and machinery to the company of large equipment manufacturing orders, raw materials can be recommended if the factory to you when ordering machine, because this kind of raw materials enterprises will generally leave a message in the equipment manufacturing enterprises, facilitate the development of business.

- Q: Do waste plastics recycling processing, the state subsidies, and now the prospects are good?

- Moreover, the after-sale service of the manufacturer is very good. So it works very well. I recommend you to Shandong Qufu (Confucius's hometown) to look at the side of field visit, actually there's a purchase as clear as noonday, Shengxin machinery Bao Aiqing is the manager of a professional, give you a ball 897026688 and ask what questions or ask professional better.

- Q: What kind of equipment do you need and how much will it cost to invest?

- Networking is the premise, at 21:28 on August 18, 2013, 57 seconds

- Q: I'd like to know all the machine names in the plastics processing industry.I would like to ask the professionals to give me some reference materials or tell them directlyThanks very much。

- If the company more money, can choose Japan's machinery, Niigata, Japan steel, Toshiba, machinery, precision parts also voltage better, don't choose oil press, less stable.To save some domestic, Haitian machine is OK, the price is relatively moderate.

- Q: Plastic processing process

- The purpose is to beautify the surface of plastic products, usually including: mechanical modification, namely with filing, grinding and polishing process, the removal of parts on edges, burrs, and fixed size; finishing, including coating surface parts, the use of a solvent to surface brightening, covered with patterned thin film surface; colour. Including painting, printing and printing; metal plating, including vacuum coating, electroplating and chemical plating method etc.. Among them, the hot stamping is heated, under pressure, the hot film on the color of aluminum foil (or other pattern film) transferred to the workpiece. Many household appliances and building products, daily necessities and so on use this method to obtain the metal luster or the wood grain and so on the pattern.

Send your message to us

FRP Grating Moulded Machine Manufacture Light Weight of Different Styles

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 21 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches