FORKLIFT SERIE - BETTERY FORKLIFT - CMAXFE3R08AC

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description of forklift:

A forklift truck (also called a lift truck, a fork truck, or a forklift) is a powered industrial truck used to lift and move materials short distances. The forklift was developed in the early 20th century by various companies including the transmission manufacturing company Clark and the hoist company Yale & Towne Manufacturing. Following World War II the use and development of the forklift truck has greatly expanded worldwide. Forklifts have become an indispensable piece of equipment in manufacturing and warehousing operations. In 2013 alone the top 20 manufacturers worldwide posted sales of $30.4 billion with 944,405 machines sold.;and the U.S. forklift market was nearly $33 billion.

Forklift cab with control layout.

Forklifts are rated for loads at a specified maximum weight and a specified forward center of gravity. This information is located on a nameplate provided by the manufacturer, and loads must not exceed these specifications. In many jurisdictions it is illegal to remove or tamper with the nameplate without the permission of the forklift manufacturer.

An important aspect of forklift operation is that most have rear-wheel steering. While this increases maneuverability in tight cornering situations, it differs from a driver’s traditional experience with other wheeled vehicles. While steering, as there is no caster action, it is unnecessary to apply steering force to maintain a constant rate of turn.

Another critical characteristic of the forklift is its instability. The forklift and load must be considered a unit with a continually varying center of gravity with every movement of the load. A forklift must never negotiate a turn at speed with a raised load, where centrifugal and gravitational forces may combine to cause a disastrous tip-over accident. The forklift are designed with a load limit for the forks which is decreased with fork elevation and undercutting of the load (i.e., when a load does not butt against the fork "L"). A loading plate for loading reference is usually located on the forklift. A forklift should not be used as a personnel lift without the fitting of specific safety equipment, such as a "cherry picker" or "cage".

Technical data of forklift:

1KG=2.2LB 1INCH=25.4MM

Mast Table FE3R06-12AC | Capacity(lb)c=500mm | ||||||||

Designtion | Lift height | Free lift | Closed mast height h1 mm | Extended mast height h4 mm | Tilt forward/ | without sideshift single solid rubber | |||

FE3R06AC | FE3R08AC | FE3R10AC | FE3R12AC | ||||||

Two-stage | 2500 | 0 | 1560 | 3430 | 3/5.3 | 600 | 800 | 1000 | 1200 |

3000 | 0 | 2005 | 3875 | 3/5.3 | 600 | 800 | 1000 | 1200 | |

3600 | 0 | 2305 | 4175 | 3/5.3 | 560 | 720 | 920 | 1050 | |

4000 | 0 | 2305 | 4375 | 3/5.3 | 480 | 650 | 800 | 950 | |

Two-stage full free | 2500 | 1450 | 1955 | 3835 | 3/5.3 | 600 | 800 | 1000 | 1200 |

3000 | 1500 | 2005 | 3875 | 3/5.3 | 600 | 800 | 1000 | 1200 | |

3600 | 1800 | 2305 | 4175 | 3/5.3 | 560 | 720 | 920 | 1050 | |

4000 | 2000 | 2505 | 4375 | 3/5.3 | 480 | 650 | 800 | 950 | |

Three-stage full free | 4000 | 1300 | 1780 | 4375 | 3/5.3 | 450 | 630 | 750 | 900 |

4200 | 1400 | 1880 | 5140 | 3/5.3 | 430 | 600 | 720 | 800 | |

4500 | 1500 | 2005 | 5340 | 3/5.3 | 380 | 500 | 580 | 700 | |

Identification | Manufacture(abbreviation) | Noblellift | ||||

Manufacturer’s type designation | FE3R06AC | FE3R08AC | FE3R10AC | FE3R12AC | ||

Drive:electric(battery or mains), | electric | |||||

Type of operation: hand, pedestrian, standing,seated,order-picker | seated | |||||

Load Capacity /rated load | kg | 600 | 800 | 1000 | 1200 | |

Load center distance | mm | 500 | ||||

Load distance, centre of drive axle to fork | mm | 250 | 260 | |||

Wheelbase | mm | 812/897 | 952/1037 | |||

Weights | Service Weight incl.battery(see line 6.5) | kg | 1740 | 1850 | 2050 | 2200 |

Axle loading, laden front/rear | kg | 1960/380 | 2235/415 | 2530/520 | 2720/580 | |

Axle loading, unladen front/rear | kg | 760/980 | 800/1050 | 860/1090 | 910/1290 | |

Wheels, | Tyres:solid rubber, superelastic,pneumatic,polyurethane | Solid rubber/polyurethane | ||||

Tyres size, front | 13×4 1/2×8 | |||||

Tyres size, rear | Ф254×82 | Ф310×125 | ||||

Wheels, number front/rear(x=driven wheels) | 2/1× | |||||

Track width,front | mm | 731 | ||||

Track width,rear | mm | 0 | ||||

Basic Dimensions | Mast/fork carriage tilt forward/backward | α/β | 3°/5.3° | |||

Lowered mast height | mm | 2000 | ||||

Free lift | mm | 0 | ||||

Lift height | mm | 3000 | ||||

Extended mast height | mm | 3875 | ||||

Overhead load guard height | mm | 2000 | 2090 | |||

Seat height/standing height | mm | 945 | 1030 | |||

Coupling height | mm | 760 | 860 | |||

Overall length | mm | 2290 | 2410 | |||

Length to face of forks | mm | 1290 | 1460 | |||

Overall width | mm | 845 | 850 | |||

Fork dimensions | mm | 30×100×1000 | 35×100×1150 | |||

Fork carriage width | mm | 845 | 850 | |||

Ground clearance,laden, under mast | mm | 70 | ||||

Ground clearance, center of wheelbase | mm | 65 | ||||

Aisle width for pallets 1000x1200 crossways | mm | 2775 | 2945 | |||

Aisle width for pallets 800x1200 lengthways | mm | 1890 | 1890 | |||

Turning radius | mm | 1040 | 1210 | |||

Performance Data | Travel Speed, laden/unladen | 8/9 | 8/9 | 7.5/9 | 7.0/9 | |

Lift speed, laden/unladen | m/s | 0.13/0.28 | 0.12/0.28 | 0.16/0.22 | 0.15/0.22 | |

Falling speed,laden/unladen | m/s | 0.22/0.22 | 0.23/0.22 | 0.16/0.20 | 0.17/0.20 | |

Drawbar pull laden/unladen | N | 1500/1700 | 1800/2300 | |||

Max puller,laden/unladen | N | 3320/3530 | 3420/3640 | |||

Gradient performance,laden/unladen | % | 8/12 | 8/12 | 10/15 | 10/15 | |

Service brake | hydr.+electric | |||||

E-Motor | Drive motor rating s2 60min | kw | 2.5 | 3 | ||

Lift motor rating at s3 15% | kw | 3 | ||||

Battery standard | DIN | |||||

Battery voltage, norminal capacity K5 | V/A | 24/360 | 24/460 | 24/540 | 24/600 | |

Battery weight | kg | 340 | 450 | 500 | 560 | |

Battery dimensions l/w/h | mm | 803/263/734 | 803/263/734 | 808/380/720 | 808/380/720 | |

Other Details | Type of drive control | Impulse AC | ||||

Operating pressure for attachments | MPa | 90 | 115 | 135 | 135 | |

Operating pressure for attachments | bar | 30 | ||||

Sound level at driver’s ear according to EN12053 | dB(A) | |||||

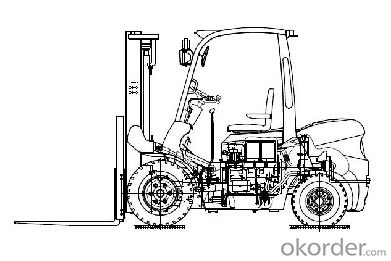

Images of forklift:

FAQ of forklift:

Q: What’s the function of forklift?

A: A forklift truck (also called a lift truck, a fork truck, or a forklift) is a powered industrial truck used to lift and move materials short distances. The forklift was developed in the early 20th century by various companies including the transmission manufacturing company Clark and the hoist company Yale & Towne Manufacturing. Following World War II the use and development of the forklift truck has greatly expanded worldwide. Forklifts have become an indispensable piece of equipment in manufacturing and warehousing operations.

Q: What’s the general operations of forklift:

A: Forklift cab with control layout.

Forklifts are rated for loads at a specified maximum weight and a specified forward center of gravity. This information is located on a nameplate provided by the manufacturer, and loads must not exceed these specifications. In many jurisdictions it is illegal to remove or tamper with the nameplate without the permission of the forklift manufacturer.

Q: What are the Forklift safety Standards?

A: 1, Forklift safety is subject to a variety of standards world wide. The most important standard is the ANSI B56—of which stewardship has now been passed from the American National Standards Institute (ANSI) to the Industrial Truck Standards Development Foundation after multi-year negotiations. ITSDF is a non-profit organization whose only purpose is the promulgation and modernization of the B56 standard.

2, Other forklift safety standards have been implemented in the United States by the Occupational Safety and Health Administration (OSHA) and in the United Kingdom by the Health and Safety Executive.

3, Driver safety: In many countries forklift truck operators must be trained and certified to operate forklift trucks. Certification may be required for each individual class of lift that an operator would use.

- Q: There are several possibilities for a forklift battery bomb

- There are several reasons for the battery explosion, first of all, the battery is caused by a normal internal short-circuit.

- Q: What is the difference between the series of internal combustion forklifts

- Together there are K, alpha Ⅱ H2000, G series, the K series 2-5 tons, alpha Ⅱ system for alpha upgrade is usually 4 -- 10 tons, the two series car belongs to the common sense of the civilians, high quality and low price. H2000 series for 1-20 tons, G series is 1-3.5 tons, 20-46 tons, belongs to the high-end car, each configuration includes the engine, transmission ratio K, alpha Ⅱ series, especially G system for the latest research and development products, and configuration of imports, the price also very similar to the imported cars, belong to large and medium-sized enterprises and export models.

- Q: How do you start a forklift without a key

- Easy to find good key door wire start a fire, all point of electricity Even with a thread and then the other two find out the starting line In connect the two together in a good two wires on the start line until the car in at the start line and even good two thread disconnect Close your car connect two good line disconnect

- Q: Is the forklift card issued by the labor bureau or the bureau of quality supervision? Which good?

- There is no such thing as a license to drive, and a lot of years of technical proficiency can be used to get a lot of credit.

- Q: What do you need to do to get a forklift license from the quality technology supervision bureau? Is there a practical test for the forklift truck?

- The driver of forklift has written test and practice exam, which is divided into two major categories, the pile test and the road test. There are different ways of testing in the area. Some areas are the actual driving forklifts, the actual operation of driving forklifts, the inspection of the rods, the line, the start, the fork, etc. This reflects the management of a region.

- Q: What is the cause of my forklift

- There are a lot of reasons why you can't start, and the owner doesn't say whether it's an internal combustion fork or a forklift truck.

- Q: People leave the forklift and do what and what to pay attention to when parking

- Before leaving the forklift, remove the cargo fork completely, hold the hand brake and remove the key of the switch. Press the emergency isolation switch. If you park the forklift on a slope, you must plug the wheels.

- Q: The forklift in the factory is a special equipment

- International standardization organization ISO/TC110 is called an industrial vehicle. Often used for the transportation of large items in storage, usually with a fuel engine or battery.

- Q: Learn the forklift truck, will you be tired in the future?

- The specific job is decided, the forklift truck general is inside the factory son, the person much worry! Hope to adopt!

- Q: Can a forklift drive into a container? Can the pallet be installed on the second floor?

- Small tonnage forklift (3 tons) can into a container, pallet items mainly depends on the item's packaging can withstand you to put on weight, can be 2 layers stacked in the outside, and then together to cross into the box. It is important to note in advance to see if the height of the layer 2 is beyond the box in the high, general goods height than some box is high enough.

Send your message to us

FORKLIFT SERIE - BETTERY FORKLIFT - CMAXFE3R08AC

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords