Food Grade Non-Smell Soft Silicone Rubber Hose

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m

- Supply Capability:

- 5000000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

[Product property]

Material: silicone rubber

Color:any available

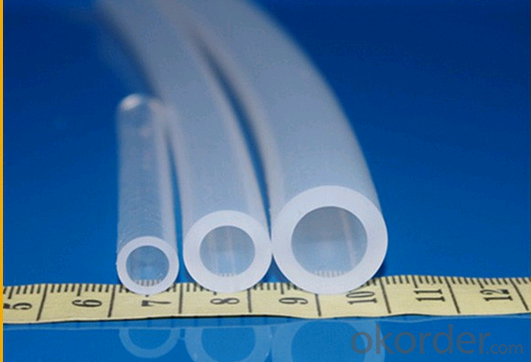

Diameter:1mm~50mm

Max Length; unlimited

Test Standard: ASTM

Tensile Strength | 5.0 Psi | ASTM D412 |

Breaking Strength | 15 K n/m | ASTM D1458 |

Elongation | 400 % | ASTM D412 |

Hardness | 45~80 Shore A | ASTM 2240 |

Temperature Range | -70-300 °C | En344 |

Density | 1.25-1.35 g/cm3 | ASTM D792 |

Breakdown Voltage | 20 KV/mm | ASTM D149 |

Pressure range | 6~12Mpa | ASTM D150 |

[Color]

Transparent, translucent, others can be customized.

[General Application]

Household electrical appliance Decorative lighting Medical instrument and drink supply

[Features]

(1)pure silicone rubber, anti-oil and waterproof

(2)Temperature resistance from -70~300 Celsius degree

(3)Anti-aging, Ozone resistance, Insulating

(4)No corrosion from copper and silver and so on.

[specification] Can be customized

1*3 2*4 3*5 4*6 5*7 6*9 8*12 10*14 10*20 12*17 15*20

Sole wall thickness: more than 0.5mm

[Customization Service]

1. Extreme heat resistance silicone hose

mostly standing 220-240C tube

mostly standing 250-280 C tube

2. Colorful silicone hose

Red, Grey, White, Black, Blue, Green

3. Flame resistant silicone hose

4. Extrusion silicone hose

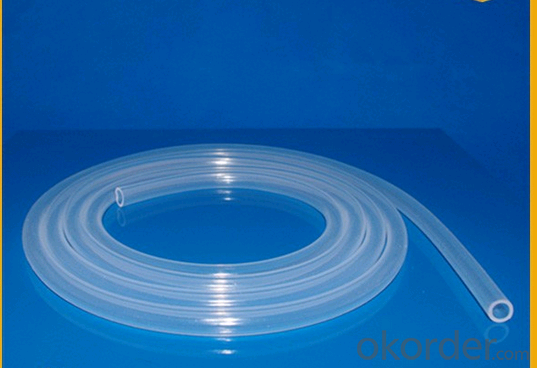

1.Silicon Tube for Fluid Transfer

Transparent Silicon Tube is offered in a variety of different options including standard, pump, and extended life pump tubing. These products have been designed to meet a range of performance requirements. Silicon Tube is ideal for extended-life pumping and in applications demanding in fluid transfer and peristaltic pump operations.

Silicone rubber is a versatile material with a host of industrial, domestic, and hobby applications. Silicone tubing is one of the products based on silicone rubber and sees use in a wide variety of industries including automotive, medical, and food production. Silicone tubing is available in a selection of different grades and structures from among three broad groups: general purpose, medical/food grade, and high pressure. All of the many types of silicone tubes do, however, feature silicone's basic characteristics of excellent thermal qualities, low toxicity, and outstanding flexibility.

2.What are different type of silicon tube

1).General purpose silicone tubes are suitable for uses which don't require high pressure hoses or high levels of compound purity.

2).The excellent thermal and flexibility qualities of silicone rubber mean that silicone tubing may be used on most domestic appliances and workshop or hobby applications.

Our Service

We can offer OEM Services

We can provide FREE SAMPPLE for our customers

We can crimp hose assembly for our customers.

We welcome clients to visit our factory leading to better understanding of our production

FAQ

Q1. Do you produce smooth or cloth wrapped cover?

A. Both, we can produce both cover, which depends on customer’s request.

Q2. Do you produce embossed marking?

A. Yes, we do provide embossed and printing markings with different color.

Q3. Can you produce product with my own brand?

A. Yes, we have been offering OEM services for 20 years.

Q4. Does your product have different color hose?

A. Yes, we currently provide black, grey, red, blue and yellow.

Q5. How long does my order take to be delivered?

A. It usually takes 5 to 30 days, which generally depends on the quantity of your order and our storage.

- Q: The small hose attached to the grease gun is coarse or fine at the joint

- The small hose attached to the grease gun is threaded with fine thread. Usually M10X1 or Rp1/8.

- Q: Hose wire is it? What's the function?

- It is used to make the skeleton material of high pressure hose, and increase the pressure resistance of the high-pressure hose.

- Q: How do the rubber tubes fit into the galvanized pipe?

- The inner diameter and outer diameter of the galvanized pipe must be determined.

- Q: Will the outside of the brake hose of the car burst apart?

- Now there is no leakage of brake oil, but also afraid of the oil leak in the running, after all, related to safety, I suggest not to save this money (brake hose is not expensive)

- Q: The use of anti slip rubber joints under what circumstances?

- Flexible rubber joint is normal for medium temperature water at 0-60 DEG C, such as special medium: oil, acid, high temperature and corrosion resistance and other hard conditions, should use special refractory material rubber joints should be relatively, not blindly on or in general.

- Q: Is the rubber pipe joint installed in the middle of the pipe and pump for shock absorption?

- Control the noise produced by parts of machinery, equipment, and equipment. The pump foundation of the new pump house should adopt heavy weight to prevent vibration from producing noise. Vibration isolation should be set up with rubber vibration isolating pads to reduce vibration noise. Each pump unit shall be provided with a foundation to prevent resonance. Use "soft" connection as far as possible in the suction pipe and pressure pipe of the pump. Periodic maintenance problems, such as packing leakage, equipment parts loose, serious wear and tear of equipment parts, mechanical vibration and so on, should be repaired in time, thereby reducing noise.

- Q: Must the hose for the cooker be made of oil resistant rubber hoses?

- When the gas combustion equipment and gas pipeline for hose connection, the design should meet the following requirements: (1) the burner of household gas stove and laboratory use, the connecting hose length should not exceed 2m, have no interface; (2) industrial production with mobile gas burning equipment, the connecting hose the length should not exceed 30m, the interface should not exceed 2;...

- Q: Faucet hose connection problem

- It is recommended to buy two kinds of hard bellows, soft metal hoses (black silk stripes). When the metal hose is installed, the joint should be horizontal or vertical, and the water pipe and gasket are not sealed properly. It will leak and do not need to be eaten with raw material.

- Q: How to identify the quality of rubber pipes for sewage treatment?

- A tubular rubber product used to transport gases, liquids, slurries, or granular material. It is composed of inner and outer rubber layer and skeleton layer. The material of skeleton layer can be made of cotton fiber, various synthetic fiber, carbon fiber or asbestos, steel wire and so on.

- Q: How much is a gas hose a metre? At least 1 meters, 5 safe?

- 1, liquefied petroleum gas will soften the ordinary rubber tube, please use special rubber tube.2, often check and clean hose, found aging, cracking, burn, rat worm bite marks, should be replaced immediately. It is recommended that the hose be replaced in two years under normal conditions.3, gas hose length of not more than 2 meters, after passing the place is not allowed to have electrical appliances.4, hose do not close to the stove surface, so as not to be flame barbecue.5, the hose does not cross the wall, doors and windows.6, do not press or fold the hose, so as not to plug, affecting the continuous gas supply.At the interface, and appliance, 7 hose valve, please use the pipe truss, to prevent the shedding of leakage.

Send your message to us

Food Grade Non-Smell Soft Silicone Rubber Hose

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m

- Supply Capability:

- 5000000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords