Flex Coat of Cement Based Protective Coating

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 kg

- Supply Capability:

- 50000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Flex Coat of Cement Based Protective Coating

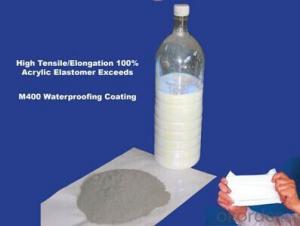

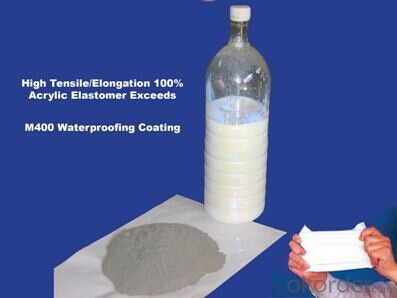

JS Waterproofing Coating

Description

JS waterproofing coating is a two component product which consists of organic polymer emulsion (liquid component) and inorganic powder compound (powder component). It is not only in a high flexibility performance as organic polymer emulsion, but also in a great durability performance as inorganic materials. Uses

Uses

It can be applied in both new and old concrete constructions which waterproofing measures should be taken, such as bridge, tunnel, reservoir, roof, basement, exterior wall, washing room and so on.

It can be applied directly to the sand, mortar, concrete surface. No matter dry or moisture condition.

It can be prepared as an adhesiveness material. The mixing proportion is: 10 times of liquid component to 20 ~ 30 times of powder component.

Advantages

1. Environmental friendly.

2. High flexibility on the waterproofing layer.

3. High durability, waterproofing, anti-aging and water resistance performance.

4. No blister would be appeared in the waterproofing layer, since the layer in a high air conductivity, even in a moisture condition.

5. It can be applied in different color.

Technical Data Sheet

Items | Specifications | |

Solid Content, %, ≥ | 65 | |

Drying Time | Surface Drying Time, h, ≤ | 4 |

Complete Drying Time, h, ≤ | ||

Stretching Time | No Treatment, %, ≥ | 8 |

Retention Rate after Heating Treatment, %, ≥ | 1.2 | |

Retention Rate after Alkali Treatment, %, ≥ | 80 | |

Retention Rate after Ultravoilet Treatment, %, ≥ | 70 | |

Breaking Elongation Rate | No Treatment, %, ≥ | 200 |

Heat Treatment, %, ≥ | 150 | |

Alkali Treatment, %, ≥ | 140 | |

Ultravoilet Treatment, %, ≥ | 150 | |

Low Flexibility | -10 degree C, no fissure | |

Impermeability | Impermeability | |

Adhesiveness strength on moisture substrate, MPa | 0.5 | |

Anti-Seepage, MPa | 0.6 | |

Applications

1. Treatment substrate surface should be evenly, solid, clean and free from water.

2. Preparing mixture in a certain proportion. If extra water is required, add water into liquid component first, mixing with a mixing machine, than add into powder component increasingly.

FAQ:

1. Q:Are you a manufactory or trading company?

A:We are a professional manufactory with 12 years’ experience and 2 years of export experience, covers an area of 30 acres.

2. Q: May I know your MOQ request?

A:MOQ is 1 TON.

3. Q: Could you offer free sample?

A:We can provide free samples to you for quality testing.

4. Q: Does your product is dangerous merchandise?

A: Not dangerous merchandise, It belongs to Not legal Inspection merchandise.

5. Q: What about your packing?

A: Liquid in IBC tank or Flexitank;Powder in woven bags.

6. Q: How about your productive capacity?

A: 900000 tons/Year.

7. Q: What is your export port?

A: China main port.

8. Q: What is your delivery time?

A: Within 7 days after received advanced payment.

9. Q: Can you print logo or label on packing as customer request?

A: Yes, we can customize according to your requirements.

Send your message to us

Flex Coat of Cement Based Protective Coating

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 kg

- Supply Capability:

- 50000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords