External Electric Motovibrators Milling Range MVE-Milling

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 20 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

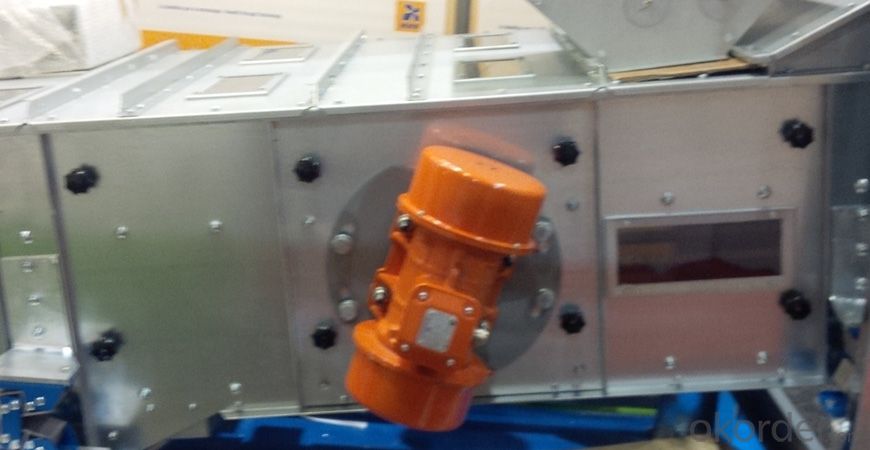

Providing 1,200 or 1,400 kg of centrifugal force with 8 or 10 poles, MVE Milling External Electric Motovibrators are designed to be applied on semolina purifier sieving machines which represent the core of any flour mill. “MVE Milling” come with ATEX ExII3D certification for opencast applications in the presence of potentially flammable dusts in hazardous environments.

---

“MVE Milling” External Electric Motovibrators consist of an electric motor housed in a sturdy FMEA-designed cast casing, with eccentric weights fitted on both shaft ends, and adopting oversized roller bearing to withstand heavy-duty operation.

“MVE Milling” External Electric Motovibrators are available with 8 or 10 pole motors only, due to low r.p.m. required for this application.

Function

“MVE Milling” External Electric Motovibrators are designed for application on semolina purifier sieving machines where the different grain components are finely separated and classified.

Each semolina purifier is fitted with two “MVE Milling” External Electric Motovibrators mounted in parallel to exploit linear centrifugal force in order to shake the sieves clean at low frequency and high amplitude. This has proven to be the best combination to obtain fine and accurate separation.

Features

Centrifugal force: 1,200 or 1,400 kg; 8 or 10 poles

Vacuum-impregnated windings using Class F insulating materials

Oversized roller bearings and sturdy FMEA-designed casing

ATEX ExII3D for hazardous environments in presence of flammable gases

Benefits

Reliable and durable due to oversized roller bearings

High centrifugal force/size ratio enabling fitting in confined space

Multiple voltages matching electric specifications worldwide

Send your message to us

External Electric Motovibrators Milling Range MVE-Milling

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 20 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords