EVA Solar Film

- Loading Port:

- NINGBO Port

- Payment Terms:

- 30%TT BEFORE PRODUCTION,70%BEFORE SHIPPMENT

- Min Order Qty:

- 10000㎡ m²

- Supply Capability:

- 1000,000㎡ Per Month m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Details Of EVA Solar Film

Specifications Of EVA Solar Film

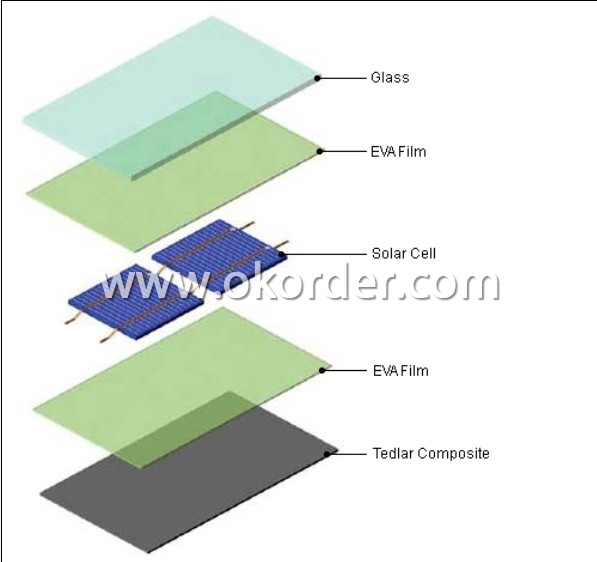

Products are encapsulating films for both silicon module and thin film one, which provide good light transmittance, adhesion property, and outstanding long-term performance. F406s is specially designed for reducing the Cell-To-Module efficiency loss of PV module. F406P/F806P provides unique PID-resistance property for silicon-module

Mechanical data Of EVA Film

Properties | Test Method | Unit | F406S | F806 | F406P | F806P |

VA content |

| -- | 30%-32% | 30%-32% | 28% | 28% |

Tensile strength | ISO 527-3 | MPa | 16 | 16 | 16 | 16 |

Elongation rate | % | 550 | 550 | 550 | 550 | |

Young Modulus | MPa | 4.7 | 4.7 | 4.7 | 4.7 | |

UV cut-off | UV-Vis | nm | --- | 360nm | --- | 360nm |

Gel content | Q/HZF 001-2010 | Gel % | >75 | >75 | >75 | >75 |

Adhesion to Glass | N/cm | >60 | >60 | >60 | >60 | |

Shrinkage | MD % | <3.0 | <3.0 | <3.0 | <3.0 | |

TD % | <1.0 | <1.0 | <1.0 | <1.0 | ||

Volume | ASTM/D527 | Ω*cm | >6*1014 | >6*1014 | >1.0*1015 | >1.0*1015 |

Thickness | GB/T6672-2001 | mm | 0.3-0.8 | 0.3-0.8 | 0.3-0.8 | 0.3-0.8 |

Width | -- | mm | 200-2200 | 200-2200 | 200-2200 | 200-2200 |

Surface | -- | -- | embossed | embossed | embossed | embossed |

EVA film is based on EVA resin which basis to ethylene and vinyl acetate copolymer resin, by adding a variety of modified additives, through melt extrusion made of the rmosetting hot melt film. Not be sticky in normal temperature, easy to operation. Produced by thermal lamination with the bonding enhanced crosslinking chemical reactions, making silicon wafers, glass, TPT multilayer material consisting of one firm bond as the product of solar panels, in actual outdoor applications up to 25 years life. A large number of applications at home and abroad well-proven solar panels, EVA film is the optimum cost performance, it is difficult to alternative packaging materials for solar cells

Advantage Of EVA Solar Film

1,Excellent durability

2,Weather resistance

3,high-temperature and high-humidity resistance

4,UV light resistance

5,Excellent adhesion to glass

6,TPT maintaining long term adhesion

7,Excellent light transmittance and transparency

8,Inactive and harmless in solar cells during processing

9,High crosslinking rate after lamination

10,Good encapsulating properties

11,Good matching with different backsheet and other materials

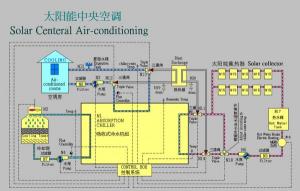

Usage/Application Of EVA Film

1. Curtain wall

2. Stair rail, skylight, awning, balcony guardrail

3. Interior partition/decorative like shower room, hotel kitchen&bath decoration.

4. Solar PV panel / LED laminated glass, coffee table, etc.

Packaging & Delivery Of EVA Solar Film | |

Packaging Detai | Packaging Detail:Export Carton and Pallet or under customer request. |

Delivery Detail:10-20days | |

Storage And Life Time Of EVA Solar Film

1,T≤30°C,H≤70%

2,Shift time is 6monthes

3,All open carton EVA film must be used up within 24hours and avoid it absorb some dust and water

1. Manufacturer Overview

| Location | Hangzhou, Zhejiang Province, China. |

| Year Established | 2003 |

| Annual Output Value | US$2.5 Million - US$5 Million |

| Main Markets | " Europe, India, South Korea, Southeast Asia " |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | |

| Language Spoken: | English;Chinese; |

| b) Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | |

Send your message to us

EVA Solar Film

- Loading Port:

- NINGBO Port

- Payment Terms:

- 30%TT BEFORE PRODUCTION,70%BEFORE SHIPPMENT

- Min Order Qty:

- 10000㎡ m²

- Supply Capability:

- 1000,000㎡ Per Month m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords