Electrolytic Tinplate of High Quality for Metal Container Thick 0.185mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 15000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Electrolytic Tinplate of High Quality for Metal Container Thick 0.185mm Description

Electrolytic Tinplate is a thin steel sheet coated by tin. It has an extremely beautiful metallic luster as well as excellent properties in corrosion resistance, solder ability, and weld ability.

2.Main Features of the Electrolytic Tinplate of High Quality for Metal Container Thick 0.185mm

Electrolytic Tinplate undoubtedly enjoys the pride of place as a packaging medium especially for food. It owes its unique position to its "nine layer sandwich structure", each of which contributes to its eminence as a packing material. The steel base of electrolytic tinplate provides the necessary strength and formability for can fabrication. The tin-iron alloy layer provides the bond between the steel and free tin layer. The free tin layer is not only responsible for the attractive bright finish and ease of solderability but is also non-toxic- a factor of vital importance in food packaging!

Tinplate is also widely used for making all types of containers such as food cans, beverage cans, and artistic cans, tea cans, painting cans, chemical package cans and dry food package cans, metal printing etc. Its applications are not limited to containers; recently, electrolytic tinplate has also been used for making electrical machinery parts and many other products.

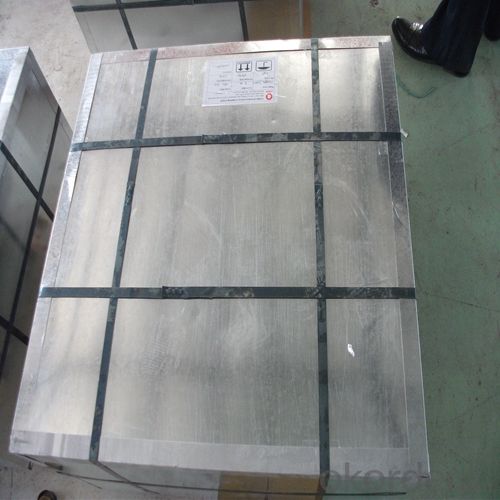

3. Electrolytic Tinplate of High Quality for Metal Container Thick 0.185mm Images

4. Electrolytic Tinplate of High Quality for Metal Container Thick 0.185mm Specification

Standard:BS EN 10202

Material: SPCC

Thickness:0.185mm

Width:700mm

Temper: T4

Annealing: CA

Coil Inner Diameter: 508mm

Weight: 6-10 tons/coil

Passivation:311

Oil: DOS

Surface: silver

5.FAQ of Electrolytic Tinplate of High Quality for Metal Container Thick 0.185mm

1. What is the delivery time for your prime quality tinplate?

Usually 35 days after order confirmation.

2. What is your Minimum Order Quantity?

Usually MOQ is 50tons for one single size, for trial order, it can be 25 tons.

3. What is the payment term?

The most common we use is L/C at sight or TT. We can also try use other terms.

- Q: What are the common applications of tinplate?

- Tinplate is commonly used for packaging food and beverages, such as cans for canned goods, metal caps for bottles, and metal containers for various products. It is also used for making aerosol cans, paint cans, and decorative tin boxes for storage purposes. Additionally, tinplate is used in the manufacturing of electronic components, automotive parts, and construction materials due to its corrosion resistance and durability.

- Q: What are the challenges faced in the recycling of tinplate?

- One of the main challenges in the recycling of tinplate is the separation of tin from the steel base. Tinplate consists of a thin layer of tin coated on steel, and separating these materials requires specialized equipment and processes. Additionally, the presence of other contaminants, such as paint or coatings, can further complicate the recycling process. Proper sorting and cleaning of tinplate waste is necessary to ensure efficient recycling and minimize the loss of valuable materials.

- Q: How is tinplate priced?

- Tinplate is typically priced based on various factors such as the current market demand and supply dynamics, raw material costs, production expenses, and market competition. Additionally, other factors like quality, specifications, and coating type may also influence the pricing of tinplate.

- Q: How does tinplate compare to other packaging materials in terms of sustainability?

- Tinplate is considered a highly sustainable packaging material compared to others. It is 100% recyclable without any loss in quality, making it an excellent choice for reducing waste. Additionally, tinplate has a long lifespan and offers excellent protection for products, reducing the need for additional packaging layers. It also requires less energy and resources to produce, further enhancing its sustainability credentials.

- Q: How does tinplate handle exposure to gases and odors?

- Tinplate is highly resistant to gases and odors, making it an excellent material for packaging and storing sensitive products. It forms a protective barrier that prevents any unwanted smells or gases from penetrating the container, ensuring the integrity and quality of the contents inside.

- Q: What are the regulations and standards related to tinplate packaging?

- The regulations and standards related to tinplate packaging vary depending on the country and industry. However, some common regulations and standards include specifications on the composition and thickness of tinplate, labeling requirements for product information and safety warnings, guidelines for food contact materials, and regulations for recycling and environmental sustainability. It is important for manufacturers and suppliers to comply with these regulations to ensure the safety and quality of tinplate packaging.

- Q: Can tinplate be used for paint can packaging?

- Yes, tinplate can be used for paint can packaging. Tinplate is a commonly used material for making paint cans due to its durability, corrosion resistance, and ability to protect the paint from external factors. It is also easy to print on and provides a smooth surface for labeling and branding purposes.

- Q: Should vacuum filling be required for tinplate meat filling?

- If the plastic bag type must be vacuum, if it is not available, it should be high temperature antivirus

- Q: Can tinplate be used for non-packaging applications?

- Yes, tinplate can be used for non-packaging applications. Tinplate's excellent corrosion resistance, ductility, and formability make it suitable for various non-packaging uses such as automotive parts, construction materials, electrical components, and decorative purposes.

- Q: What are the common printing and decoration techniques for tinplate?

- The common printing and decoration techniques for tinplate include lithography, offset printing, hot stamping, embossing, and varnishing.

Send your message to us

Electrolytic Tinplate of High Quality for Metal Container Thick 0.185mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 15000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords