PVC Tape Adhesive - Electrical Insulation Tape Black Color Factory Tape

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 roll

- Supply Capability:

- 100000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description of KC71 Tape

• KC 71 is a self-amalgamating ethylene propylene rubber (EPR) tape used on solid dielectric cable for electrical insulation and jacketing in splices up to 69Kv and for building stress cones in terminations up to 35kV.

• The tape comes with a separator that is removed during the taping process.

• Its 0,76mm thickness and quick amalgamation facilitates a rapid, void free insulation build-up that is electrically stable and moisture proof.

• KC 71 is suitable for use with conductors rated at 90°C with an emergency overload rating of 130°C.

• The tape is also resistant to corrosion, chemicals and ultra violet light.

• KC 71 fully meets the Table 1 requirements for Type III tape in ASTM D 4388.

Dimensions of KC71 Tape

1” x .030” x 16.4'

25mm(width) x 0.76mm(Thickness) x 5m(length)

Consult us for other sizes

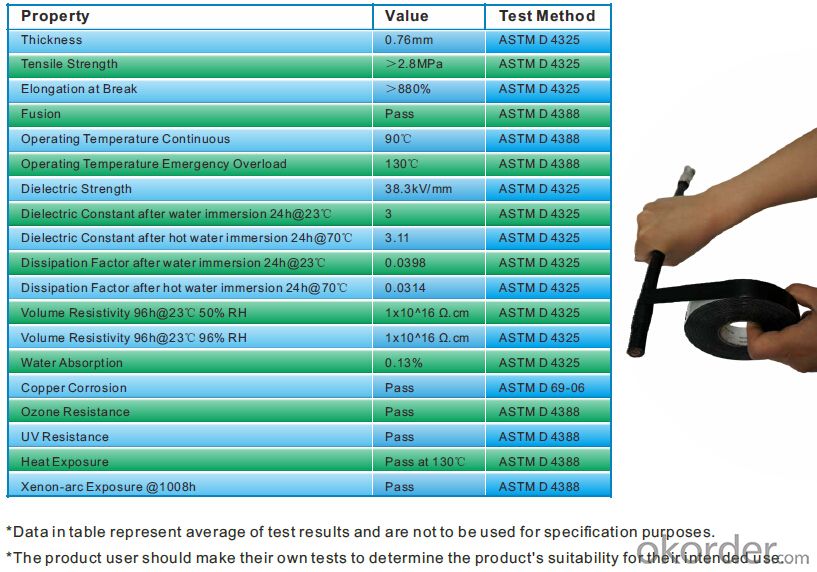

Specifications of KC71 Tape

Applications of KC71 Tape

• Electrical insulation and jacketing in splices of solid dielectric cable up to 69kV

• Building stress cones in terminations of solid dielectric cable up to 35kV

• Jacketing of indoor terminations

• Bus bar insulation and corrosion protection

• Jacket repair and restoration in all types of cable

• Moisture sealing applications

FAQ

Q1.Can we have the customized size tape?

A1:Consult us for other size

Q2:Is this Tape environmental-friendly?

A2:This tape is flame/arec resistance and environmental-friendly.

Q3:Can we have the sample/trail order to test quality?

A3:Surely we support the sample/trail order.

- Q: What about antistatic tape and insulating tape?

- The use of adhesive tape, 1. boxes fixed, protect all kinds of products anti-static tape2. provide protection during production3., widely used in metal, plastic, glass, ceramics and other materials, such as electronic products, plastic parts fixed, laminated glass and so on4. antistatic tape is used for electrostatic sensitive products or anti-static area as a warning role

- Q: PVC electrical tape, and insulation tape difference

- [insulating tape]Refers to electrical insulating tape used to prevent leakage, insulation tape. Also known as insulating tape, adhesive tape, composed of baseband and pressure-sensitive adhesive layer. The base band is made of cotton fabric, synthetic fiber fabric and plastic film. The adhesive layer is made of rubber and tackifier. It has good adhesion and good insulation. Insulating tape has good insulation, pressure resistance, flame retardant, weather resistance and other characteristics. It is suitable for wire feeder, electrical insulation protection and so on.

- Q: PVC insulation tape can withstand high temperature for a long time without aging failure

- Is a company engaged in the production of adhesive tape and tape cutting processing of production-oriented enterprises, the company is located in Guangzhou economic and Technological Development Zone, the eastern side of the traffic is very convenient. Company main products are: 1, high temperature resistant tape (finger tape, PI tape, Teflon tape, textured paper tape, PET tape, Mara tape) 2, conductive type, insulation and flame retardant adhesive tape, foil tape, foil (aluminum foil, glass fiber, acetate cloth tape, PVC electrician floor tape, tape, cloth tape, flame retardant) 3, double-sided tape (a substrate without substrate double-sided tape, non-woven double-sided tape, VHB foam tape, 4), the operation of various types of imported tape (3M tape, NITTO, Nitto, TESA SONY SONY TESA tape, tape, temple Kong TERAOKA tape, Japan DIC tape)

- Q: What are the polyethylene film sleeves?

- According to the construction mode of adhesive tape winding, determine the width of anticorrosive adhesive tape. Manual winding, do not use too wide tape, the construction of workers when the intensity is not easy to control, it is best not to exceed 150mm width; manual mechanical entanglementWinding (part of the simple mechanical and human coordination) visual conditions, but the maximum width should be 230mm; mechanical winding can be appropriate to relax the width of tape, but it is best not to exceed 300mm.Polyethylene film is a commonly used plastic film, because of its non-toxic, so a lot of food used for making packaging bags. Notice the difference between PVC and polyvinyl chloride (PVC). The simple way is to make the polyethylene film for ignition, and the non flammable is PVC film.A separation layer between a polyethylene film, a barrier layer, an intervening coil, and concrete or other protective layer. It is also considered a separate protective layer.

- Q: How many or how many hours can the scotch tape decompose?

- The mechanical strength and electrical insulation are good, but its heat resistance is poor, softening point is 80 degrees, at 130 degrees, began to decompose, change color, and precipitation of HCI (chemical substances)

- Q: How to set the polyethylene anticorrosive adhesive tape?

- 3. According to the winding construction method of adhesive tape, the width of anticorrosive adhesive tape is determined. Don't use the manual winding tape is too wide, the construction workers when the efforts are not easy to control, it is best not to exceed 150mm wide; manual mechanical winding (with some simple mechanical and visual), but the maximum width is 230mm; the mechanical winding tape width appropriate to relax, but preferably not more than 300mm.

- Q: What material is the base material of PVC electric tape?

- The base material is slightly foamed PVC plastic, and the pressure-sensitive adhesive is applied on the bonding surface, and the adhesive effect is achieved

- Q: Why are bare wires tied with black tape?

- PVC electrical tape.Electrical tape is coated with a layer of rubber pressure sensitive adhesive. Polyvinyl chloride film (PVC film) has the characteristics of electrical insulation, flame retardancy and weather resistance, and rubber pressure-sensitive adhesive has initial adhesive strength and adhesive strength. It is suitable for all kinds of wire and cable insulation winding,

- Q: What are the differences between electrical tape and electrical tape? Which ones are used in those industries?

- Electrical tape is called polyvinyl chloride electrical insulation adhesive tape, and some people call it electrical insulation tape or insulating tape.

- Q: Points above to get the glue paper tape on the door to deal with

- Styrene also has the same effect, so styrene can also be used

Send your message to us

PVC Tape Adhesive - Electrical Insulation Tape Black Color Factory Tape

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 roll

- Supply Capability:

- 100000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches