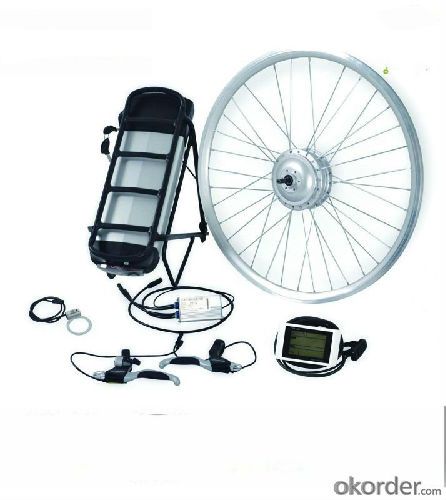

E-bike Motor 250W 36V, Electric Bike Kit, Spare Parts

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 set

- Supply Capability:

- 15000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction

We are professional do e-bike kits business for many years for the customers all over the world, and have met so many troubles, with these troubles, we have much experience on e-bike kits today.

Our e-bike kits are easy to install and allow you to convert your standard bicycle into an fun and eco-friendly e-bike. Since every model is different and components will vary, it's your responsibility to determine the best way to install an electric bike kit on your bike. Although most of the steps are similar from install to install, we have instructions can help the customers to convert their bicycle.

We have build the Europe after-sale service center in Europe to repair the parts including motor, batteries, controller etc, also for the whole ebikes repairing. As one of the pioneer seller for ebikes in china, BTN aims to master clean energy technique, and develop energy-saving and environmental-friendly ebikes.

Our Advantages and Characters

1). Adopted ISO9001 management system strictly control every aspect of production

2). The automation of production to ensure the consistency of product quality

3). Adopt top raw materials lays the foundation for the quality of products

4). Every employee attentively makes each motor

Motor Specifications

Rated Power(W): | 250 |

| Rated Voltage(V) | 36 |

| Max Speed(rpm): | 285 |

| Rated Efficiency (%) | ≥78% |

| 2P: | 20 |

| Reduction Ratio: | 1:4.35 |

| Weight(kg): | 2.8 |

| Over Lock Dimension(mm): | 100 |

| Spoke Specification: | 12G/13G |

| Cable location: | Shaft center,right |

| Hall sensor: | Optional |

| Integrate speed sensor: | Optional |

| Limitied Current(A) | 0.7 |

| Brake type: | V/Dics brake |

| Surface: | Silver/Sliver painted/Black/Black painted |

| Noise(db): | ≤55 |

| Salt fog test(h): | 24/96 |

| Water proof Grade: | IP54 |

| Certification: | ROHS EN15194 |

FAQ

1.Which country do you mainly export to?

A: Our products are very popular in Mid East, India, South East Asia, Latin America, Africa.

2.Q: What’s the advantage of you compared with other suppliers experienced in foreign trade?

A: We have been specialized in FRP products for over decades years and approved by many domestic companies. Except for our quality and price, we’re also able to give you the best service.

3.Q:Can you provide some samples?

A: Yes, of course. We will send you samples for your confirmation before you place firm orders.

- Q: Can electric cars need no controllers?

- May, the positive and negative ends of motor connected to a battery, a power supply to open high-speed operation, unable to control the speed, extremely unsafe; will affect the service life of the battery, easy to make the motor brush burn, this is turn is not effective.The role of controller in the electric vehicle, the motor running speed (by speed control switch to transfer speed numerical Holzer element in the structure), braking system, speed display system, speed limits and other functions like human organs, are indispensable.

- Q: How to measure the electric motor's good or bad?

- Connect to a multimeter. Use a DC voltage of 10 volts, and the red line is connected with the red one. Black, respectively, with three other lines, one at a time, turn the wheel with one hand, angle, the multimeter should have voltage, 4V and 0V change is normal, otherwise it is not normal, and the three are measured in the same way.

- Q: How can electric motors be solved?

- This is divided into two major categories, you need to investigate.1, electric cars;2 batteries;3, that the operation;

- Q: My electric car just bought less than a month, when I bought a car, I think the motor sound is big, but people who buy cars say no problem. But I am still a little worried, I hope you help see, the situation is as follows: as long as the starting motor, there is noise, glide when there is no sound. Note that the motor starts much larger than the other motors. So I would like to ask you whether it is a quality problem or what is the problem. Thank you again

- Normal, because the electric motor is a DC inverter power supply, electric cars now are brushless motor, and click on the material is made of aluminum, in order to shield motor magnetic field, so the use of aluminum shell

- Q: What's the difference between an electric wheelchair and an electric bicycle?

- Electric wheelchair mechanism. A long box reducer for electric wheelchair is using a brush motor, the motor speed per minute at 3000 rpm, while the electric wheelchair with the actual speed is 110 rpm, the braking torque in 50Nm, therefore we need to slow down and to increase the torque reducer, so electric wheelchair motor connected to a gearbox is the power of reason, the electric bike is a brushless motor, and he requires speed, braking torque is small, there is no deceleration institutions will look smaller,Motor electric wheelchair structure power was about 300W, the electric bicycle power is about 100WBecause the use of different scope, manufacturing cost is different, so the price is different,Electric wheelchairs, electric bodies, each price about 800, electric bicycle motor at about 500 each.

- Q: Holzer model for electric cars

- Motor Holzer (a total of 3), after opening, you will see the coil has 3 Holzer, are generally switch Holzer, such as: OH44E, unipolar switches, OH41 bipolar latch, or OH41F bipolar latch, etc.. Do you use bipolar latch Holzer, or do you use unipolar Holzer?. This is determined by the phase of the motor: there are stators (fixed magnets) and rotors (rotating coils) in the motor. To the coil power (the current through the coil) will produce a (S or N) and the stator magnetic field will attract or repel force. The power of the motor from the attraction and repulsion force. What time is absorbed or what time it will repel each other at the same time, Holzer gives a signal to change the direction of the current in the coil (coil to change S or N pole),You can see: OH series, Holzer selection, or YS series Holzer, all kinds of models have.

- Q: What is the principle of electric car locks, Holzer? What's the connection between these two?

- In this way, the car will feel very difficult to drive, to play the purpose of locking the motorHolzer, however, is a magnetic field detector that detects changes in the magnetic field

- Q: 48V20AH how many watts of electric cars, controllers and motors?

- It consists of program counter, instruction register, instruction decoder, timing generator and operation controller. It is the decision-making organ of issuing commands, that is, the operation of coordinating and directing the whole computer system.

- Q: Electric car motor five fine wire (Holzer line) come together, Holzer will be bad?

- BadElectric motor five wires are positive and negative line, Holzer line three

- Q: Electric car boring how to do?

- Electric bicycle motor boring, check the following three reasons:1, two wheel bearings are good, rack up idle to know; if not good, friction, resistance big, change first. A few dollars will be enough.

Send your message to us

E-bike Motor 250W 36V, Electric Bike Kit, Spare Parts

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 set

- Supply Capability:

- 15000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords