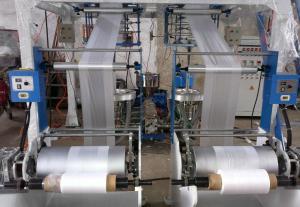

Double-head Film Blown Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 20 Sets per Month set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Detailed Product Description of Double-Head Film Blown Machine

Both the cylinder and the screw of the extruder are made of high quality alloy steel \ with the best hardness and corrosion

Usage of Double-Head Film Blown Machine

This machine set is used for blowing Low-density polyethylene (LDPE) and high- density polyethyene (HDPE) plastic film to make various vest bags and flat-rim bags which have been widely used for packing in the food industry, garment industry and textile industry, etc.

Features of Double-Head Film Blown Machine

Both the cylinder and the screw of the extruder are made of high quality alloy steel through nitration and precision finishing with the best hardness and corrosion resistance.,Scientifically designed, this machine set has two heads for one extruder with such advantages as increasing production capacity, saving energy, labour and workshop area, etc

Main Technical Variables of Double-Head Film Blown Machine

Mode | SJ-60FM-600 | SJ-60FM-700 | SJ-65FM-800 |

Diameter of screw | 60MM | 60mm | 65mm |

Screw Ratio(L/D) | 28:1 | 28:1 | 28:1 |

Screw Speed | 10-110r/min | 10-110r/min | 10-110r/min |

Mad.Output | 40kg/h | 55kg/h | 70kg/h |

Max.Folding Windth of Film | 550mm*2 | 650mm*2 | 750mm*2 |

Single-sided Thickness of Film | 0.006-0.10mm | 0.006-0.10mm | 0.006-0.10mm |

Power of Main Motor | 15kw | 18.5w | 22kw |

Total Power | 26kw | 30kw | 35kw |

Weight of Machine | 3000kg | 3800kg | 4500kg |

Overall Dimensions | 4800*2200*3800mm | 5000*2400*4000mm | 5200*2600*4200mm |

- Q: PVC blow molding and rolling film difference

- Blow molding: a method of forming a hollow product by expanding a hot melt parison closed in a mold by means of a gas pressure,

- Q: What does blister machine do?

- The cabinet wardrobe door covering filmChasing the answerPaint free door will also be used

- Q: What what plastic products should use "rolling, extrusion, blow molding, pressing, plastic, rotational molding and injection"?

- 4, pressing molding, the use of: often used cotton, glass cloth, paper, asbestos cloth, etc., the resin has phenolic, epoxy, unsaturated polyester, and some thermoplastic resin.5, the use of plastic molding, the main principle is: the flat hard plastic sheet is heated to soften the vacuum adsorption on the surface of the mold, cooling after molding, widely used in plastic packaging, lighting, advertising, decoration and other industries6, rotational molding, usage: rotational used are polyethylene, polyamide, polycarbonate, polystyrene modified cellulose and plastic etc..7, use: injection molding, injection molding is suitable for almost all of the thermoplastic plastic injection molding, molding cycle is short (seconds to minutes), the quality of molding products from a few grams to tens of kilograms, can form a complex shape, accurate size, with metal or non metal insert molding the.

- Q: What brand is good blister machine?

- I just do advertising design. Yesterday, I just made a blister. The cost is very high

- Q: For example, three roller calender, the size of the three roller models are the same, or is there a big difference?

- Are the same, that is, there is a spindle, two transmission shaft, 3 roller diameter is 18 inches

- Q: How to choose an automatic plastic suction machine?

- 2. price. General plastic suction machine if the price is less than 100 thousand, mostly low matching or semi-automatic. Really good automatic plastic suction machine import configuration, high-quality steel, high-quality assembly master, these costs are not less than 100 thousand, the price is about 150 thousand. Petty gains, no good goods.

- Q: I want to buy a new fully automatic blister machine. I wonder if that made brand is good What's the price? How many pieces can be produced in a day with a 1000*450 thick plastic suction disk?

- Generally 10 tens of thousands, you may be using PS! See how thick you use PS, and the high end of the mold, the size of the product are related.

- Q: Is the roller mill in the plastics industry a special type of work?

- Material temperature to about 150 degrees to shape, in high temperature, a large number of plasticizers, smoke volatilization. Exposure to lead smoke, hydrogen chloride gas and so on.Remark: only the molding workers who produce PVC products are limitedFor more details, please see:Reply of the Ministry of personnel on light industrial labor jobs early retirementScope of work for early retirement of light industry

- Q: Blister machine rules and matters needing attention

- I. operating procedures1, turn on the power switch, enter the compressed air machine template, automatically, according to the size and the actual packaging is packing, adjust the pressure, the pressure of the appropriate air pressure, increase the speed, pressure plate, the greater the pressure.2, the machine power supply socket 220V circuit, then open the machine, bakelite mold installed on the turntable, the turntable and the terminal line.3, counterclockwise rotation driven plate, observe the platen automatic pressure is normal, without exception, start packing on the bakelite mold plastic cover paper, open the heating switch, switch the heating time, from large to small adjustment of current conversion system, according to the actual size of the mold, select the appropriate changes and the heating current the heating time and cooling time, adjusted to the satisfaction.

- Q: Which manufacturer does calendering machine do better? Be anxious?

- What do you look at the main rolling mill production process, what is the Suzhou dongfulai, doing good, they are mainly based on the customization process

1. Manufacturer Overview

| Location | Zhejiang, China (Mainland) |

| Year Established | 2009 |

| Annual Output Value | US$2.5 Million - US$5 Million |

| Main Markets | South America Southeast Asia Africa Mid East Eastern Asia Domestic Market |

| Company Certifications | CE |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Ningbo Port,Shanghai Port |

| Export Percentage | 91% - 100% |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b) Factory Information | |

| Factory Size: | 3,000-5,000 square meters |

| No. of Production Lines | 5 |

| Contract Manufacturing | Design Service Offered |

| Product Price Range | AVERAGE |

Send your message to us

Double-head Film Blown Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 20 Sets per Month set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords