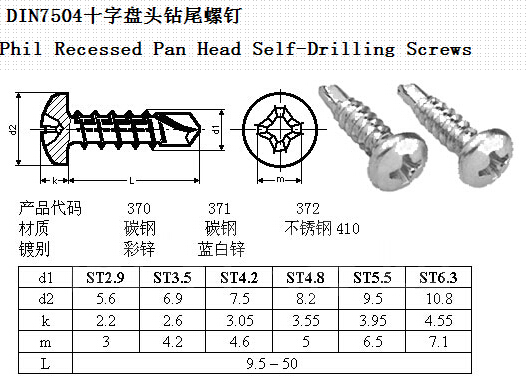

DIN7504 Phil Recessed Pan head Self-Drilling Tapping Screws

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 10000000 piece/ pieces per month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Name | DIN7504 Phil Recessed pan head Self-drilling Tapping Screws |

Material | Carbon Steel, Stainless Steel 201/ 304/ 316 or others. |

Size | 8#-18*13 ~ 14#-14*125 |

Standard Model | DIN ANSI JIS ASTM |

Min Order | 1000piece/ pieces |

Packaging & Shipping

Packing | Inner Box + Carton Box + Pallet or Under Your Requirement |

Supply capacity | 10000000 piece/ pieces per month |

Delivery time | 5~20 days after deposit |

Export market | Asia, America, Europe, Africa, markets. |

Our Services

1. Reliable Supplier |

2. High Quality |

3. Standard Producing Technology |

4. Competitive Factory Price |

5. Fast Delivery |

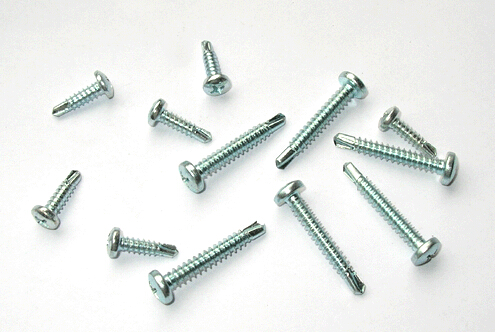

Product Picture:

- Q: Why the screw thread more closely, spin into the more effort?

- Screw thread more dense, indicating the screw thread deep and shallow, the screw in the advance the resistance of the smaller, when the spin naturally more effort.

- Q: What tools are used to remove the screws, the two lines are grooves, the middle of a paragraph is convex

- Motor on a lot of screws on this one, one by one in the middle of a word with a knife set a trough can be used

- Q: What is the difference between Chinese-made screws and US screws?

- China-made screws and the United States is no essential difference between the screws, and now the world are using the screws in China.

- Q: The mirror under the mirror put the toilet glass is broken, the original screw rust deformation, and pulled out. How to rust the screw

- First with gasoline drops into the gap, a few minutes later and then drip a little oil, wipe the cross groove, and then screwdriver twist, not on the use of clamp clamp clamped after the screw, such as cross recess round, On the use of steel saw saw a word slot, for the word screwdriver twist, the last one with a drill to the bolt screw off, re-drilling punching.

- Q: A tightened screwdriver has been damaged, that is, the cross into a round mouth, and now I need to get it out for a new one, is there any way to take it out?

- If the screw nail head on the outside, you can use the hacksaw saw a word again, and then use a relatively large one screwdriver out, if it is Shen head head, only slowly with a file to do, and then screwdriver.

- Q: There are some screws, is installed in the electrical, power, electronic products on the material, ask how to correctly install the screws?

- A small screw, but has a great impact, how to use a small screw, so that the role of the maximum screw, these are the things we need to learn, we should know that the screws are small, but less screws It is absolutely impossible. We have a good understanding of the correct use of the screw on the method. If we have a screw on our hands, then we can go to understand the characteristics of the screw, you can understand the above raw materials, you can in the specifications, hardness above to understand, we only have a comprehensive understanding of the characteristics of this screw, we To be able to correctly use this screw, otherwise, we will never play a small screw the biggest role.

- Q: How did the scrHow did the screw become round?ew become round?

- (1) in the screwdriver head pad things such as double-sided adhesive, non-woven fabrics, etc. If there is no condition, then the paper can be, so you can increase the friction. (2) with a small amount of 502 glue into the screw hole, and then screw into the screw, and so the glue after the solid tip and then use the tip of the screw to pull out the screw (only the screwdriver is not afraid of causing screw teeth). (3) fruit screw cap exposed, you can use the tip of the clamp clamp screw cap after the screw. (4) the general mobile phone screws are metal, the case is plastic, not screw down when the time. You can use the tip of the screw into the screw cap, the metal screws to screw the plastic around the plastic melting, with the tip of the clamp clamp, gently pull out! You can also force down the screws about 1 mm (be careful not to engage in the chassis), you can solve the problem of loose screws. (5) so little the screw is not easy to get, my father had to repair the original bike screw method, with a small electric drill in the middle of the screw to play a not deep hole, and then find an anti-silk tap into the (must Anti-wire tap, it is difficult to find, to go to a large measuring blade cutting shop), you can unscrew the.

- Q: What does the screw m4x6 mean?

- M for the flat wire (not self-employed screw) 4 for the diameter, 6 for the length. Units are generally millimeters

- Q: how to use Motor washer

- What gasket, rubber reduces vibration, metal reduces pressure

- Q: How to remove the broken screw?

- Drill a properly sized hole on the jumper screw, insert a pyramid or change it into a reverse thread, and screw the screw in the reverse thread and then unscrew the screw in the usual way.

Send your message to us

DIN7504 Phil Recessed Pan head Self-Drilling Tapping Screws

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 10000000 piece/ pieces per month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords