DIN125 Flat Washer M3-M48

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 10000000 piece/ pieces per month pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Product Description

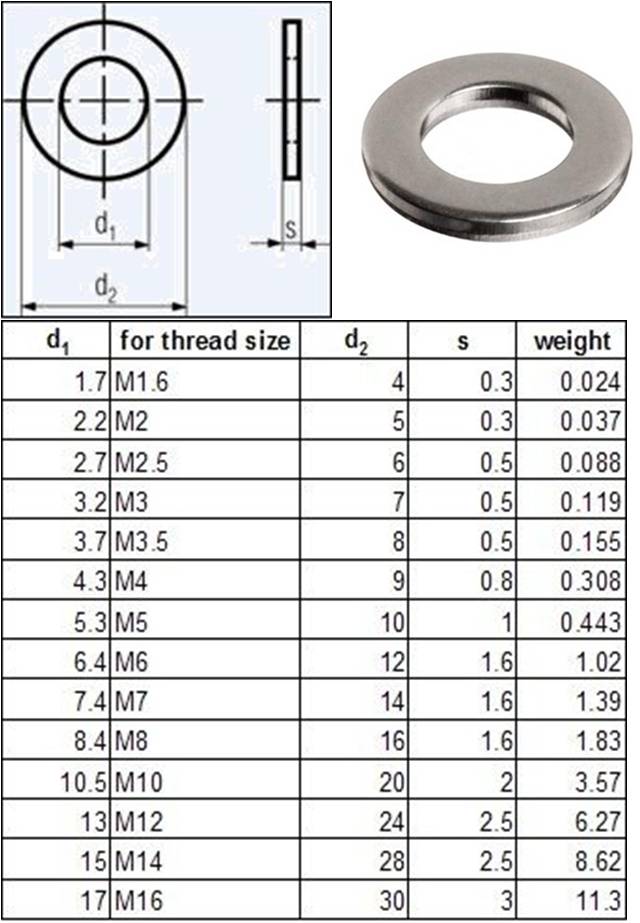

Product Name | DIN125 Flat Washer M3-M48 |

Material | Carbon Steel, Stainless Steel 201/ 304/ 316 or others. |

Size | M3--M48 |

Standard Model | DIN ANSI JIS ASTM |

Min Order | 1000piece/ pieces |

Packaging & Shipping

Packing | Inner Box + Carton Box + Pallet or Under Your Requirement |

Supply capacity | 10000000 piece/ pieces per month |

Delivery time | 5~20 days after deposit |

Export market | Asia, America, Europe, Africa, markets. |

Our Services

1. Reliable Supplier |

2. High Quality |

3. Standard Producing Technology |

4. Competitive Factory Price |

5. Fast Delivery |

Product Picture:

- Q: What is a screw? What is a nail? What is the concept? What is the difference!

- Machine nails are mechanical bolts, mainly due to mechanical connections, due to smaller size mechanical screws

- Q: Specific conditions for use of spring washers

- The conditions for the use of spring washers are as follows:The application of spring washer, can be applied to the following four standards: standard spring washer (GB93-1987), light spring washer, (GB859-1987), heavy spring washer (GB7244-1987).The purpose of the spring washer is to prevent the nut from loosening. In the national standards are illustrated. The six corners of the slotted nut is matched with the bolt and screw for end with hole, so that the split cotters inserting screw nut from the groove in the hole, preventing the nut macnaught loose, mainly used for vibration load or alternating load applications.

- Q: Gasket 300HV relative to what material?

- For the 140HV level can choose 08F, 08Al and 10, 10F, etc., the surface hardness can reach about 140HV

- Q: What is the effect of the screw?

- Special purpose screws such as rings are used for lifting parts.

- Q: For example, some people ask us to assemble the time zone of the flat washers of the positive and negative side, I would like to ask the installation of flat washers have positive and negative points? If yes, how to distinguish?

- Generally, but if the request is high, there is a round face near the nut.

- Q: The main meaning is that the design to make some specific requirements to achieve consistency.

- Referred to the selection must be selected in the national standard parts, otherwise the changeability does not exist. Speaking of norms nothing less than the following: function according to national standards (strength, rust, shape ....);

- Q: Want to fix something, which is a triple iron (do not know how thick), would like to ask what screws can be turned into? Can ordinary drill go in? The question is to consider the drill or consider the screw, or have to consider? Thank you! The

- Self tapping screw is a screw, on, do not have to pre-open the thread, it will spin out the thread, the Chinese name "self-tapping screws."

- Q: Inside the hexagonal screws, rather not down, it may be too much screw on the screw too tight has been bad 3 screwdriver screw is too small also one-half of rice grain please help think about ways

- Skip the screws before tapping a few times. Sprinkle the rust on the screw, it should be easy to win.

- Q: how much Specification for washers

- Stop washer is used in conjunction with nut to prevent loosening of the nut washer. General is divided into round nut with a stop washer, the outer tongue stop washer, ear stop washer, single ear stop washer, etc..

- Q: What's the meaning of the "200HV" of the gasket material? Is that the hardness level? What materials are usually chosen? Know predecessors please advice, younger brother is not very grateful!!!

- Surface Vivtorinox hardness, general requirements not less than the number of commonly used non-ferrous metals, such as bronze, tin bronze, etc.

Send your message to us

DIN125 Flat Washer M3-M48

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 10000000 piece/ pieces per month pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches