Cylindrical Roller Bearing , Chinese Factory N 2306 E High Precision

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 set

- Supply Capability:

- 100000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Specifications:

Specification | Model No.: N 2306 E |

Brand Name: OEM | |

Size:30*72*19mm | |

Net weight: 0.370kg | |

Material: Chrome steel | |

Cage: Brass, Steel | |

Features: | 1) Precision: P6 P5 P4 P2 |

2) Noise level: Z1, Z2, Z3, Z4 | |

3) Vibration Level: V1, V2, V3, V4 | |

4) Clearance: C2, C3, C4 | |

5) Hardness: 58-63 HRC | |

6) Greese: As your requirement, such as SRL, PS2, Alvania R12 and so on. | |

Packing | 1.Industrial packing: box |

2.Commercial packing: box then into standard carton/wooden Box | |

3.According customer's requirement | |

Payment | T/T, L/C, Western Union |

Delivery time | About 3 to 5 working days |

Services | Warrantee: 1 year |

Samples: available | |

OEM: available | |

Free technical support and after-sales service |

Packaging & Delivery

Packaging Details: | plastics wrapping bearings - wrapping papers - polywoven bag - carton for outside package - wooden box /According to your order |

Delivery Detail: | 30-40days/according to your order |

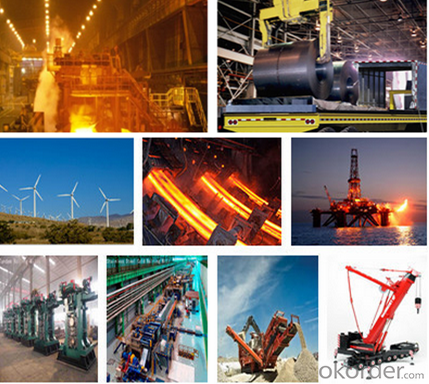

Product Applications:

Cylindrical Roller Bearing Application Flied:Rolling Mills,Crusher,Mining

Metallurgy Petroleum,Chemical Industry,Engineering Machinery,Port,Oil,Gas,

Wind,Agriculture,Lathe,CNC,Steel Works,Electrical Machinery,Axle/Limber,

Tractor,Autocar,Crude Oil Engine and so on.

FAQ:

1.Why Choose us?

Profession and reliability.

Directly sale.

Honest manufacturer.

We have a heart like fire

We are ready to serve you all the time .

2.Can you make non-standard bearing?

We have great techincal team can provide

OEM service and technical support for you

3.Can you send me the free sample?

Yes.We can supply sample if have stock,we need charge freight cost or if you have courier account for freight collect .

4. How can I get more information ?

Feel free send us enquiry or call ,we do best at your service for 24 hours

- Q: How to check the thrust cylindrical roller bearings?

- However, in the conventional design, there are few checking bearings, as long as the shaft and shell meet the intensity requirements on the line, because the manufacture of bearings than ordinary mechanical parts to be much more stringent (except shoddy products).If you do your homework, do it according to the design manual.

- Q: What are the differences between cylindrical roller bearings nu208m and nu208em?

- E means "reinforced", "rolling", "thickening", "change", "change".. Hope to adopt!!

- Q: Cylindrical roller bearings NUP2311E mounting dimensions: Da (max): 69Da (min): 64DB (min): 72DC (min): 80Da (max): 111What are the specific meanings of these dimensions? Thank you, master

- Da means shoulder diameter, that is to say, the maximum shoulder size is 69mm, and the minimum is 64mm

- Q: Why does cylindrical roller bearings fail abnormally?

- Generally, the causes of abnormal failure of cylindrical roller bearings are as follows:1, cylindrical roller bearing manufacturing accuracy is poor, one end of the bearings with loose, and travel source is larger, bearing frame rigidity is poor. Or the bottom of the bearing seat is uneven.2, cylindrical roller bearings axis misalignment (misalignment) axis and the housing of the shoulder to the surface is not vertical, shell installation, bearing two or more holes, different axis.

- Q: How should I find the concentricity of cylindrical roller bearings after installation?

- So, in the machining process, try to use special fixtures and parts drawing in tol and other measures to avoid such a remedy".

- Q: What are the components of cylindrical roller bearings?

- Compared with the deep groove ball bearings of the same size, this kind of bearing has larger radial load capacity, and is also suitable for high-speed rotation from the structure.

- Q: For example, NU, NJ, N, RNU, NUP, NF, NO, NN, RN, what do you mean, who can tell me about that hero?

- N outer ring without edge, inner ring double edgeRNU no inner ring, NU typeNUP outer ring, double retaining ring, inner ring, single edge, with flat retaining ringNF outer ring, single edge, inner ring, double edgeNO doesn't know

- Q: What kind of material is used for cylindrical roller bearings?

- Ah, you ask what material to do, of course, with the bearing steel do ah. Bearing steel, however, is well distributed. Generally use GL15#

- Q: Thrust cylindrical roller bearings, the main use?

- Our factory uses the bearings of Changzhou Enke Bearing Co., Ltd., they have many kinds of bearings and meet various demands.

- Q: Why should the main shaft be coupled with double row cylindrical roller bearings?

- Because double row cylindrical roller bearings with high carrying capacity, high precision, separation, easy installation and disassembly, mainly used in lathes, milling machines, machining centers and other high-precision machine tool spindle. Hope to be of help to you.

Send your message to us

Cylindrical Roller Bearing , Chinese Factory N 2306 E High Precision

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 set

- Supply Capability:

- 100000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords