Customized 0.025-0.08mm thick cold stamping medicine foil 8021 8079

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 200 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Cold-formed medicine foil is one of the indispensable key materials in modern pharmaceutical packaging. Its excellent barrier properties and excellent forming ability make it an ideal choice for protecting the quality of medicines and extending the shelf life. By combining high-strength aluminum alloys and advanced coating technology, cold-formed medicine foil can not only resist the damage of oxygen, moisture and light, but also adapt to complex packaging design requirements, providing comprehensive protection for the safety and stability of medicines.

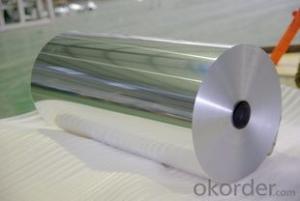

Aluminum foil base alloy for cold-formed medicine foil: 8021-O state aluminum foil, 8079-O state aluminum foil, thickness of 0.025-0.08mm; with high cupping value, high heat sealing strength, no pinholes, good sealing and other advantages. It is a supplier of raw materials for cold-formed medicine aluminum foil for various foreign pharmaceutical packaging companies.

Structure of cold-formed aluminum foil:

Cold-formed aluminum foil is usually a multi-layer composite structure, which is composed of aluminum foil and other barrier materials to ensure that the packaging has excellent mechanical strength and barrier properties. The common structure is three layers:

OPA (nylon) layer + aluminum foil layer + PVC (or PP) layer

Nylon (OPA) layer: the outer layer material, which provides high tensile strength and impact resistance for cold-formed aluminum, making it not easy to break during the cold forming process, and also provides certain barrier properties.

Aluminum foil layer (Al): the middle layer, usually 45-60 micron thick pure aluminum foil, is the main barrier layer, with extremely high moisture resistance, oxygen resistance and light resistance, effectively protecting the stability of the drug.

Polyvinyl chloride (PVC) or polypropylene (PP) layer: the inner layer material, directly in contact with the drug, has good heat sealing and chemical resistance to ensure the safety of the drug and the sealing of the packaging.

8021 8079 cold-formed aluminum foil performance advantages:

1. Excellent barrier properties: effectively block gases (such as oxygen, water vapor) and light radiation, protecting drugs from external influences.

2. High sealing: compounded with a variety of materials to form a firm sealing structure to ensure the stability and safety of drug packaging.

3. Excellent mechanical properties: high strength and high toughness, heat and low temperature resistance, able to withstand various stresses and deformations.

4. Easy to process and form: suitable for various processing techniques, meet different drug packaging needs, and adapt to automated packaging equipment.

5. High safety: non-toxic, odorless, environmentally friendly, will not pollute drugs, and has good chemical stability.

6. Protect drug quality: keep drugs dry and moisture-proof, extend shelf life, and good light-shielding properties to prevent deterioration.

7. Easy to carry: light and easy to carry, convenient for patients to use.

Cold Formed Pharmaceutical Foil Specifications:

| Alloy | 8021, 8079 |

| Material | OPA/AL/PVC |

| Temper | O |

| Thickness | 0.025-0.08mm |

| Width | 100-1600mm |

| Length | C |

| ID | 76mm |

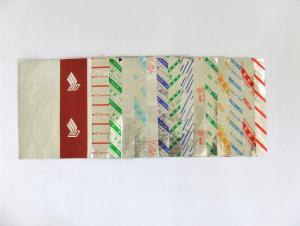

| Application | Used for heat sealing with hard aluminum foil to package capsules, pills or tablets. |

| Features | 100% barrier to water vapor, gas, light, etc. |

| HS code | 76072000 |

| Packaging | Standard seaborne export packaging - fumigated wooden box |

| Certificate | ISO9001 and ISO14001 |

Chemical composition (%):

| Alloy | Al | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Single | Total |

| 8079 | Remainder | 0.20 | 0.30 | 1.0-1.6 | 0.10 | 0.6-1.3 | 0.10 | 0.25 | 0.10 | 0.05 | 0.15 |

| 8021 | Remainder | 0.50-0.90 | 0.6-1.0 | 0.10 | 0.20 | 0.05 | 0.05 | 0.10 | 0.08 | 0.05 | 0.15 |

Cold-formed medicinal aluminum foil processing requirements

1. Flat plate shape;

2. Strict requirements on the plate surface, no black oil spots, scratches, small black silk, bright lines, roller-printed concave and convex points, mosquitoes and other phenomena;

3. No pinholes or holes, and pinholes must be eliminated if found;

4. Edge cutting quality, no burrs, towers, layer channeling, ruffles, flanging, and concave and convex lighting phenomena;

5. Water brushing must meet Class A standards;

6. Moisture-proof packaging to avoid oxidation.

Faq:

Q1. What product information do I need to provide?

A1: You need to provide the grade, width, thickness, coating and the tonnage you need to purchase.

Q2: Can you send samples?

A2: Of course, we can provide you with samples for free, you only need to bear the express fee.

Q3: How long is your delivery time?

A3: Generally speaking, our delivery time is within 15-20 days, and it may be delayed if the demand is extremely large or there are special circumstances.

Q4: Are the products quality inspected before loading?

A4: Of course, all our products are strictly quality inspected before packing, and unqualified products will be eliminated.

Q5: When is your payment term?

A5: Usually we adopt T/T and L/C or a combination of both.

- Q: Such as the title: this insulation foil usually can get viscous tropical buy where (small buy), I'm going to ask the hardware stores and supermarkets are not the adhesive foil? Is it called "aluminum foil tape"? If yes, please advise, thank you!

- All those selling refrigeration parts and central air-conditioning are available

- Q: Home water heater exhaust pipe insulation material need to wrap it, please can Naiduo high temperature aluminum foil? Can you meet the requirements?

- Aluminum foil is directly pressed into aluminum, melting point: 660.37, burning point: 550 degrees Celsius

- Q: What is an aluminum foil woven bag?

- (3) high temperature (121 DEG C), low temperature (-50 DEG C), good oil resistance and good incense retention.(4) non-toxic, tasteless, in line with food, drug packaging hygiene standards.(5) good heat sealing property, softness and high barrier property.

- Q: What is a composite aluminum foil molded poly vinyl foam board, and what is a composite aluminum foil extrusion poly vinyl vinyl insulation board, the two how to distinguish?Please try to be more specific

- The composite aluminum foil insulation board is used for air conditioning and air duct insulation1, the insulation material molded type insulating materials used is moulded polystyrene foam board, also known as EPS, commonly used household appliances packaging materials is the white foam foam board; the extruded insulation material is extruded polystyrene foam board, which is XPS.

- Q: What size is the aluminum foil bag?What are the commonly used sizes?

- Aluminum foil bag, also known as "anti-static aluminum foil bag", "pure aluminum bag."". Appearance: opaque, silver gray.

- Q: What is the difference between aluminum foil and aluminum foil?

- The supermarket of the aluminum foil and aluminum foil is the same. (you can see the material description.)

- Q: Aluminum foil for food packaging materials, why?

- Because aluminum foil has smooth surface, light weight, good light shielding, not easy to corrode, non-toxic, easy to process and so on

- Q: When the wire is made, it needs a layer of foil inside, and the outside is insulated. Why is that?

- Insulation is done outside to protect or leak electricity.Cable foil is the use of aluminum foil sealing and shielding, single or double coated plastic film, an aluminum foil plastic composite #

- Q: Export data for aluminum foil

- The development of packaging industry in China has greatly affected the consumption of aluminum foil industry. During the "12th Five-Year" period, the construction of livelihood projects and the development of low-carbon economy will have a strong demand for high-performance aluminum foil.

- Q: Why can copper foil and aluminum foil shield electromagnetic signals?

- In addition because the copper or aluminum oxidation caused by the contact resistance increases, the long-term use of suggestions for tinned copper foil, shielding effectiveness after 2 years will not fall too much. I have a new measurement of shielding effectiveness of copper foil and tinned copper foil at the beginning are basically the same, 114dB (copper 1GHZ) and 112dB (tinned copper 1GHZ). The shielding effectiveness of one year after the 84dB (copper 1GHZ) and 110dB (tinned copper 1GHZ). The effect is really bad.

Send your message to us

Customized 0.025-0.08mm thick cold stamping medicine foil 8021 8079

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 200 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products