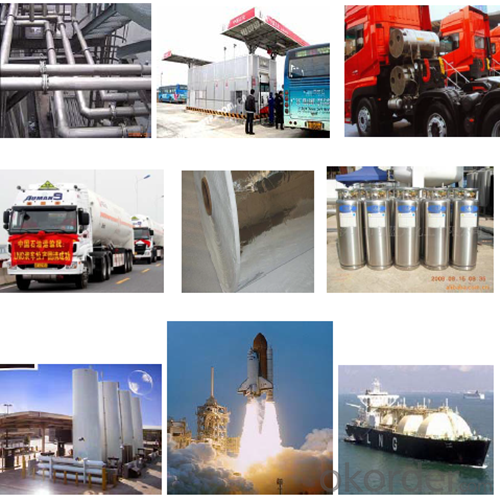

Cryogenic Insulation Paper for Dewar Containers, LNG

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details for Cryogenic Glass Fiber Insulation Paper for Dewar Vessel,LNG

| Feature: | Fire-Proof | Pulp Material: | Wood Pulp | Pulp Style: | Recycled |

| Pulping Type: | Chemical-Mechanical Pulp | Place of Origin: | Shandong, China (Mainland) | Brand Name: | Shandong Pulp and Paper |

| Model Number: | MP-402 | Weight: | 12±2.0 g/m2 | Thickness: | ≤0.055mm |

| Tensile Strength: | ≥0.031(KN/m) | Harmful Element: | No harmful element | Size: | Customized |

| Color: | White |

Packaging & Delivery

| Packaging Details: | Normal packing with plastic bag and carton box |

| Delivery Detail: | 15 days |

Insulation Paper

Cryogenic insulation paper, made of the raw material of super fine glass micro fibre through special processing technology production, is usually used with aluminum foil. It is used as a kind of thermal insulation materials of vacuum multilayer insulation structure storage container used for cryogenic liquid (liquid helium, liquid hydrogen, LNG, liquid oxygen, liquid nitrogen, liquid argon, etc.).

Welcome to Visit our factory

- Q: I would like to ask how the process of cryogenic treatment

- Biology: fast cooling, can prevent the crystallization of cells in the water, does not destroy the cell organization. In the preservation of sperm, organ preservation, food preservation, preservation of certain life and so onMedical treatment: cryotherapy, treatment of certain skin diseasesSpace: the space environment simulation, satellite ground test station, using liquid helium, create -200 degrees of low temperature.Noise: high sensitivity radar telescope, using liquid helium cooling, receiving device, noise reductionVacuum: the use of cold well technology can get high vacuum

- Q: Can the cryogenic phase control the cooling rate?

- 1, the principle of liquid nitrogen refrigeration: storage of liquid nitrogen in the container through the liquid in the sublimation of heat to take away the heat of the workpiece heat. Liquid nitrogen refrigeration can not be reused after the need to add a new liquid nitrogen, a large range of cooling rate, cooling temperature range of 0-196 degrees C.

- Q: How many changes in the properties of the cryogenic metal?

- 10 diamond drill footage of 231.2 meters to 595 meters.11 M6 high speed steel fibers processing aluminum casting parts 1200 40012 high speed steel milling cutter cutting area of copper 350 pieces of 750 pieces13 cutting blade YT798 area A3 51 square meters to 98 square meters14 cutting blade YT798 area ZG15Gr1M01 7 square meters to 12 square meters15 YT330 blade ZG15Gr1M02 for 6 minutes 19.8 minutes16 YT15 blade cutting length 20# low carbon steel 3M 7M17 YT30 blade cutting length 20# low carbon steel 5m 9.7M

- Q: Cryogenic treatment to improve what performance?

- Cryogenic treatment (cryogenic treatment) refers to the materials needed at -190 DEG C to -230 DEG C under treatment. Suitable for all metal or nonmetal material, such as alloy, carbide, plastic (nylon and Tie Fulong), aluminum, ceramics etc..

- Q: Ultra low pressure casting mold useful, how to arrange the process? Thank you

- The size stability of die casting die is mainly solved by the following aspects:1, in the die casting process and mold temperature stability under the premise of the mold size! To ensure product size!2, in the design of die casting products, according to the way the product and the simulation of the temperature field, the type of product, the direction of contraction and so on to develop the contraction ratio, the general product shrinkage rate of about 5/1000! Step by step cumulative experience!3, die casting mold in the production period of time, (for example, 5 thousand to 10 thousand times), can do stress treatment, ABP treatment, etc.! In order to reduce the internal stress in the production process of the mould, it can achieve the purpose of stabilizing the size, preventing the fracture and increasing the service life of the die!Want to help you!

- Q: What is the meaning of vacuum cooling in heat treatment

- Placed for a period of time, known as cryogenic treatment, under normal circumstances are usually treated with liquid nitrogen.

- Q: What is a cryogenic fast line

- Equipment is compressor, heat exchanger and expander (or throttle). The compressor and expander generally use a reciprocating or turbine. Commonly used heat exchanger coil type, shell and tube type or plate heat exchanger. Deep freezing technology, can the nature of the study of materials near absolute zero, and can be used for the separation of liquid and gas mixture of gases. Industry can get liquid oxygen, liquid, gas, etc.; Can be effectively separated from the air

- Q: What is the meaning of cryogenic technology in the mechanical process, what is the specific practice?

- Copper alloy, hard alloy, plastic, glass and so on to improve the uniformity of low temperature, stable size, reduce deformation, improve service life

- Q: What is the meaning of deep frozen

- Frozen food can make the flavor and nutrient retention is best, and it is said that at -35 deg.c, food oxidation reactions are very slow, that is to say deep freezing over the food nutrition and flavor of fresh food with little difference. In short, deep frozen to fresh.

Send your message to us

Cryogenic Insulation Paper for Dewar Containers, LNG

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords