Corrugation Sheet Roll Former machine for sale

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 15 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

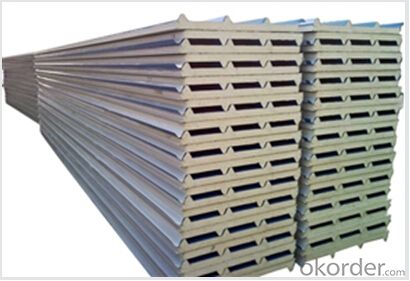

Corrugation Sheet Roll Former

Technical data of Corrugation Sheet Roll Former

Suitable Material | Q235 color steel sheet;0.3-0.7mm | |

Working speed | About 20m/min | |

Power Requirement | Main motor power: 5.5 Kw(Depend on final design) | |

Hydraulic station power: 2.2 Kw(Depend on final design) | ||

Material of forming rollers | No.45 steel, plated with chrome on surface. | |

Material of cutter | Cr12 mould steel with quench treatment, HRC58-60 | |

Material of shaft | High quality 45# steel, Dia. is 72mm. | |

Shaft diameter | 72mm | |

Controlling system | Mitsubishi PLC & converter | |

Total weight of machine | About 7000KGS | |

Machine's size | About 15m×1.8m× 1.5m (Depend on final design) | |

Our Metal Roll Forming Machine's advantages

| 1. Anti-rust roller: CNC machine tooled, Plated with 0.05mm hard chrome . 2. Heat treatment: Heat treatment for cutting frame to remove the steel stress, to avoid deformation. 3. Cutter blade: Cr12 mould steel with quenched treatment, long life time. 4. High precision: shafts for rollers are tooled by grinding machine at least twice. Rollers are CNC processed to ensure precision performance. 5. People originate: introduced Mitsubishi PLC with touch screen. Friendly man-machine interaction. 6. Excellent services: Technician can be sent to your factory to install the machine and train your workers. Lifttime services for our machines |

- Q: What is a CNC machine?

- Control machine is a digital control machine for short, is a program control system with automatic machine tools.

- Q: What are the types of machine tools?

- Machinable range is very wide, rotary body, spiral body, plane, groove, gear and so on.

- Q: What is the main part of CNC machine tools?

- CNC machine work, do not need workers to directly operate the machine, to control the CNC machine tools,

- Q: How many kinds of machine tools

- NC bending machine, CNC rotary head presses. CNC special machining machine; This machine includes CNC wire (electrode) cutting machine tools, CNC EDM machine tools, CNC flame cutting machine,

- Q: The Function of Machine Tool Body in CNC Machine Tool

- 2. Main drive system: its function is to achieve the main movement.

- Q: What is the difference between turning and milling machine and other machine tools?

- 2, it is not only a simple set of machine tools, but also a lot of special internal loop function, such as online measurement, online compensation, simultaneous processing, vertical conversion and so on special features, and these special features is the true value of turning machine

- Q: How about CNC machine tools

- According to the control of machine tool movement classification: point control CNC machine tools, linear control CNC machine tools, contour control CNC machine tools

- Q: How to categorize cnc lathes

- There are many varieties of CNC machine tools, according to its processing, control principles, functions and composition, can be classified from the following several different angles.

- Q: CNC machine tools and general machine tools in the detection of the biggest difference between the machine

- In particular, CNC machine tools are now the general batch accuracy within 0.02MM, is difficult to proportion of ordinary machine!

- Q: The processing range of the lathe

- Horizontal lathe is the most commonly used kind of lathe, its wide range of technology, can carry out a variety of surface processing, such as inside and outside cylindrical surface, conical surface, ring groove and forming surface, face, thread, drilling,

Send your message to us

Corrugation Sheet Roll Former machine for sale

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 15 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords