Construction Hoist with Siemens Electric Parts

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Construction Hoist Description

The general building hoist manufactured by our company have the features as good quality, long life, wide application range and convenient for maintenance. The gearing adopted bearing,enameled cable, and oil seal. The electric parts adopt products from worl renowned manufacturers such as Schneider, Siemes, and LG. The racks and pinion adopts specal material and heat-treatment technique, which prolong the life of these parts. The steel structure uses quality steel from famous domestic manufacturers. The surface of the structure can apply paint-spray, parkerizing baking finish or hot galvanizing processing according to users requirments. The cage can be produced and decorated by aluminum molded board, punched-plate or figured aluminum board.

Main Features of Construction Hoist

1. The recomended cage dimension(L*W*H)(m): 2.0*1.0*2.5, 2.5*1.0*2.5, 2.5*1.3*2.5, 3.0*1.5*2,5, 3.2*1.5*2.5, 3.8*1.5*2.5, 4.0*1.5*2.5, 4.2*1.5*2.5 etc. We can also manufacture cages of other size according to the user.

2. The cage and the door material can be aluminum molded board, punched-plate, figured aluminum board or other type according to yout requirements.

3. The mast section and the tie-in surface can adopt paint-spray, or hot galvanizing processing..

Construction Hoist Specifiction

SC series product also has special design, such as reinforced guide rail with cross-section of 800mm, inclined type, special for cooling tower, etc. All the double cage building hoist can be changed into single cage type,

| Type | Payload(kg) | Lifting Speed (m/min) | Motor Power(kw) | Safety Device | ||

| Twin Cage Hoist | No Counterweight | SC100/100 | 2*1000 | 33 | 2*2*11 | 2*SAJ30-1.2 |

| SC120/120 | 2*1200 | 33 | 2*2*11 | 2*SAJ30-1.2 | ||

| SC160/160 | 2*1600 | 33 | 2*2*11 | 2*SAJ30-1.2 | ||

| SC200/200 | 2*2000 | 33 | 2*3*11 | 2*SAJ40-1.2 | ||

| SC250/250 | 2*2500 | 33 | 2*3*11 | 2*SAJ50-1.2 | ||

| SC270/270 | 2*2700 | 33 | 2*3*15 | 2*SAJ50-1.2 | ||

| SC300/300 | 2*3000 | 33 | 2*3*15 | 2*SAJ50-1.2 | ||

| SC320/320 | 2*3200 | 33 | 2*3*15 | 2*SAJ50-1.2 | ||

| With Counterweight | SCD200/200 | 2*2000 | 33 | 2*2*11 | 2*SAJ40-1.2 | |

| SCD250/250 | 2*2500 | 33 | 2*2*11 | 2*SAJ50-1.2 | ||

| SCD270/270 | 2*2700 | 33 | 2*2*15 | 2*SAJ50-1.2 | ||

| SCD300/300 | 2*3000 | 33 | 2*2*15 | 2*SAJ50-1.2 | ||

| SCD320/320 | 2*3200 | 33 | 2*2*15 | 2*SAJ50-1.2 |

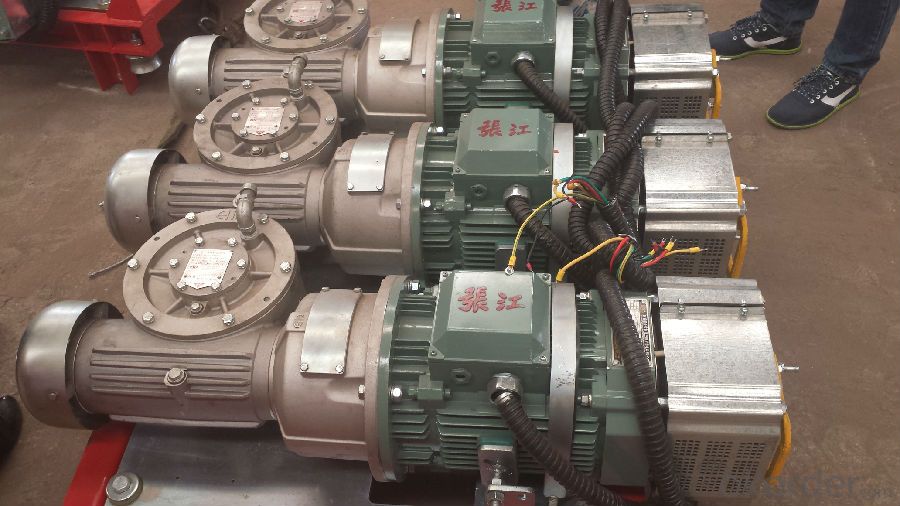

Images of Construction Hoist

FAQ of Construction Hoist

Q: What is the building hoist main purpose?

A: Building hoist equipped with double or single cabin to transport the materials and labors up and down. It's the ideal

construction equipment for vertical transportation in the field of construction.

Q: What is the main structure of building hoist?

A: The P/M construction hoist mainly contains metal structure, driving system, electrical control system, cable guide & protection system, electrical top crane and safety device.

Q: What is the dimension of the cage?

A: Normally the cage dimension is 3X1.5X2.5M (L/W/H) for 2t type hoist. Details should be checked according to our quotation sheet. Also, the size can be customized according to the factual site condition. There are two doors (entrance& exit doors) for each cage, It can be produced as up & down sliding or ramping model for safety and convenience.

- Q: Can construction elevators be taken by people or by goods

- The construction elevator can be taken either by person or by cargo Material hoist (dragon door frame, well frame) can be carried only, not by person

- Q: What measures can be taken to guarantee the smooth and reliable operation of a building hoist during lifting?

- <p>To ensure the smooth and reliable operation of a building hoist, regular maintenance and inspection are crucial. This includes checking the hoist's mechanical components for wear and tear, ensuring the electrical systems are functioning correctly, and verifying that all safety mechanisms are in place and operational. Additionally, proper lubrication of moving parts, adherence to load limits, and operator training on safety protocols are essential. It's also important to use hoists that meet safety standards and to avoid overloading. Regularly updating and upgrading the hoist system can also enhance reliability and safety.</p>

- Q: A lift motor is 7.5 KW, and the frequency converter sends current 4.2 A, which has A heating resistance in the converter, and how the charge is calculated when the lift is full. Or consider the power of the converter and the power of the thermal resistance.

- Try using the security software. There is a cracked version

- Q: This question asks for the proper steps to install a building hoist, a device used in construction to lift materials and workers.

- <p>To install a building hoist correctly, follow these steps: 1) Ensure the site is suitable and inspect the hoist for any damages. 2) Assemble the hoist tower on a solid, level base. 3) Install the mast and guide rails according to the manufacturer's instructions. 4) Attach the hoist mechanism and cab, ensuring all connections are secure. 5) Conduct a thorough inspection and test the hoist's functionality. 6) Obtain necessary permits and inspections from local authorities. 7) Train operators on the safe use of the hoist. Always adhere to safety guidelines and manufacturer's specifications.</p>

- Q: This question asks for the criteria or factors to consider when selecting a building hoist for a particular construction task.

- <p>Choosing a suitable building hoist involves considering several factors: the weight capacity required for the materials you need to lift, the height of the building or structure, the frequency of use, and the available space for installation. Ensure the hoist complies with safety standards and regulations. Consider the hoist's speed and efficiency, as well as the ease of maintenance and operation. Consult with hoist manufacturers or experts to assess your specific needs and select the most appropriate model for your construction project.</p>

- Q: This question asks for a comparison of the pros and cons associated with the use of building hoists in construction projects.

- <p>Building hoists offer several advantages, including increased efficiency in material transportation, reduced labor costs, and improved safety by minimizing the need for manual handling at height. They can also be used for personnel transport, enhancing site accessibility. However, there are disadvantages such as high initial costs, the need for regular maintenance and inspection, and potential downtime due to mechanical issues. Additionally, they require space for installation and can obstruct views or access during operation. Safety concerns also arise if not properly managed, as accidents can occur due to operator error or mechanical failure.</p>

- Q: Is it permissible to use personal manual equipment for lifting objects instead of a construction hoist?

- <p>While it might be tempting to use your own manual equipment for lifting objects, it's generally not recommended for construction purposes. Building hoists are specifically designed for heavy lifting and are equipped with safety features that manual equipment may lack. Using manual equipment can pose significant safety risks, including the potential for accidents and injuries. Always follow safety regulations and use the appropriate equipment for the task at hand to ensure the safety of everyone on site.</p>

- Q: For example, what records do you want to have a third party monitoring?

- The elevator overhaul formalities; First report to the local special court, after the approval of the major repair, the major repair unit should have a major repair record to leave the record of party a, including the replacement parts or the procedure that changes. Then the local special inspection hospital will be required to check again.

- Q: What is the capability of a building hoist in terms of lifting large objects?

- <p>Yes, building hoists are designed to lift and transport large objects in construction settings. They have a high load capacity, often ranging from several hundred to several thousand kilograms, depending on the model and specifications. Building hoists are equipped with safety features to ensure secure lifting and are commonly used for moving materials such as cement, bricks, and heavy equipment within multi-story buildings under construction. However, it's crucial to adhere to the manufacturer's guidelines regarding weight limits and safety protocols to prevent accidents.</p>

- Q: Is it possible to utilize a building hoist for elevating construction materials at construction sites?

- <p>Yes, building hoists are commonly used for lifting materials at construction sites. They are designed to transport heavy construction materials and personnel vertically, which is essential for multi-story construction projects. These hoists are equipped with safety features and are operated by trained personnel to ensure the secure and efficient movement of materials and workers.</p>

Send your message to us

Construction Hoist with Siemens Electric Parts

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords