Composite API Hot Spring Pipe High Pressure GRE Pipes DN 40-300mm

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 1000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

API Hot Spring Pipe

1.Standard:API,ASTM,ISO,GB, etc

2.Anti-corrosion & high strength

3.Long service time

4.Low costs

GRE (Glass Reinforced Epoxy)

Some times, GRE and FRP/GRP (Fiber/Glass Reinforced Plastic) are regarded as the same

material with different names, but in most cases, since GRE choice epoxy resin as material,

it has stronger performances.

It is the thermosetting plastic products combining the reinforced material of fiberglass roving with the base material of epoxy resin.

It is made by mechanical filament wound process controlled by computer.

So it is a kind of composite material.

The GRE pipe offers a unique combination of chemical resistance, size stability, high strength, and thermal/electric non-conductivity.

So the GRE pipe can be used in the fields of chemical anti-corrosion, construction, electric insulation, power development etc.

Features:

1. Anti corrosion

2. High strength, more safety

3. More than 30 years service life

4. Light weight, easy installation and keeping cost

5. Flexible design and shorter reform term

6. No medium pollution

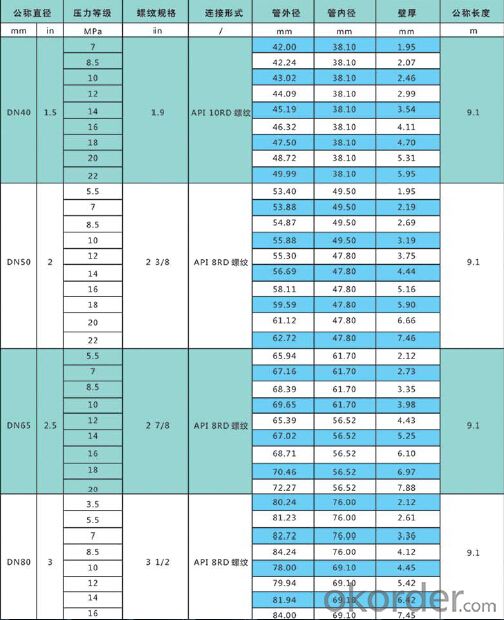

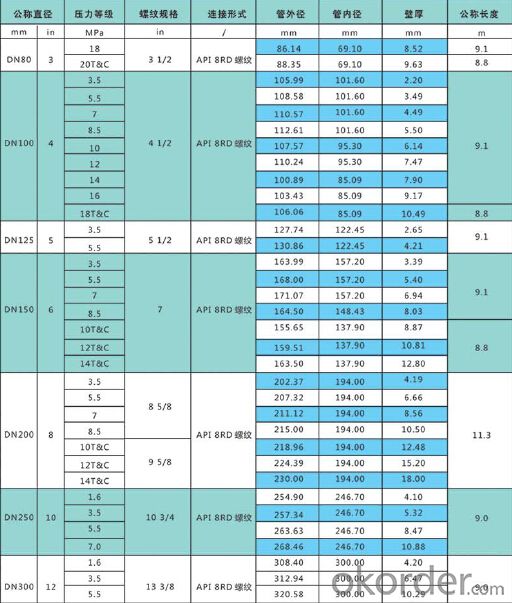

Technical Table

Applications:

1.Oil, petroleum, natural gas pipeline

2.Irrigation, hot spring, city water pipeline

3.Brine delivery pipeline

4.Other liquid transport pipeline

Strength:

1.High quality

We're state owned manufacturer with registered capital RMB 200 million specialized in this area.Standard:API-15HR,API-15LR,ISO9001,GB,etc.

2.Competitive price

Our raw material is from PPG SINOMA JINJING FIBERGLASS CO.,LTD, a JV enterprise

invested by our company and PPG industries to ensure high quality and low costs.

3.Great production capacity and short delivery time.We have 16 production lines for GRE pipe, with annual production capacity of 16000MT.

Pitcures of our factory:

FAQ of GRE pipes:

Q1: What’s the performance standards?

Lianzhong pipe is designed to meet all of these ASTM , AWWA, BS, DIN standards.

Q2: What’s the qualification testing for the products?

Lianzhong pipe has been rigorously tested to verify conformance to the ASTM D3262, ASTM D3517, AWWA C950 and DIN 16868 requirements

Q3: How long can I receive my goods?

A: Usually, we will deliver products within 20 days after the contract is signed. Delivery time is negotiable when necessary.

- Q: Mending method for glass fiber reinforced plastic pipe

- Other repair methods: choose resin, accelerator, curing agent, high quality glass fiber cloth. Don't let the powder go. It is autumn, the temperature is low, so to put more than summer curing agent, the proportion of the curing agent, accelerator, resin; 1:1.5:8 with glass fiber wrapped around the pipe, coated on the glass fiber cloth for glass steel with a good quick, let the glass steel glass fiber cloth fully soaked, waiting for glass steel fully cured, and then repeated several layers. It will be strong.

- Q: What can be done to solve the leakage of FRP pipe?

- The method of mending is hand paste. The stones must be taken away so that the pipes are restored to their original shape. If you can get into the pipe, polish it first and repair the lining.

- Q: What's the process of continuous winding glass fiber reinforced plastic sand pipe?

- (1) die: the continuous flat steel supported by the reel, winding to form a round mandrel.(2) feeding: when the mandrel moves, advanced packing, glass fiber, resin and surface material are accurately placed under the control of program control (PLC) and microcomputer (PC).(3) monitoring: according to the prepared material input program, only the basic pipeline data can be input; the computer can calculate the mechanical operation settings by itself. Material consumption, pipe thickness and so on will be constantly monitored and recorded.(4) curing: induction heating of the curing process of the product is accomplished by the flat band and the infrared device which is directly heated in the product. The temperature of 20 different parts of the product in the curing zone will be measured and displayed in the form of an image on the computer screen.(5) cutting and trimming: the pipe can be cut from 0.3 meters to 18 meters under the predetermined length. The cutting, chamfering and caliber measurement are coordinated with the longitudinal movement of the product to ensure the accurate vertical cutting of the glass fibre reinforced plastic pipe and the killing of the outer diameter.

- Q: What's the difference between glass fiber reinforced plastic pipe and glass fiber reinforced sand pipe?

- Sand sandwiched glass fiber reinforced plastic pipes only have more than one sand sandwiched with glass fiber reinforced plastic pipes, and sand layer can be understood to replace glass fiber with quartz sand. The sand pipe with the same thickness is compared with the glass fiber reinforced plastic pipe, but the sand holding pipe is cheap, but the strength is poor; and the glass steel pipe is opposite.

- Q: What are the specifications of glass fibre reinforced plastic cable pipes? What are they?

- Strong corrosion resistance, insulation, non magnetic, acid, alkali, flame retardant, anti-static. The utility model has the advantages of good elasticity of bending modulus, complete solution of the corrosion of the metal pipe, no distortion and elasticity, and the defects that the plastic tube is easy to aging and the impact resistance is poor. Good water resistance, can be used in damp or water for a long time without deterioration. Due to the specific properties of glass fiber reinforced plastic, the service life of the glass steel pipe is more than 50 years. The construction is convenient, in particular the repair project, the efficiency is particularly prominent, is the power cable communication cable engineering, municipal engineering and road underground cable is the most ideal protective device, the cable bridge across the river, the use of the most suitable and convenient.

- Q: What kind of diamond saw blade for cut glass steel pipe?

- Diamond saw blade is a kind of cutting tool. It is widely used in the processing of concrete, refractory, stone, ceramics and other hard and brittle materials. The diamond saw blade is mainly composed of two parts: matrix and cutter head. The matrix is the main supporting part of the bond of the cutter head, the cutter head is the cutting part during use, the cutter head can be in use and constantly consumed, and the matrix is not, the cutter head is able to cut the role because it contains diamond, diamond as the hard material of it friction cutting object is processed in the knife head. The diamond particles are wrapped in metal inside the cutter head.

- Q: Uneven settlement of the foundation, can lead to glass fiber reinforced plastic underground water pipes burst, what is the principle?

- Dislocation will cause the pipe to burst. The pressure is different, and the pipe will burst

- Q: What is the compressive strength of all kinds of FRP materials?

- Anti fouling and anti moth: unsaturated polyester resin surface clean and smooth, will not be ocean or sewage in the shellfish, fungi and other microorganisms stained, moth, so as to increase roughness, reduce water cross section, increase maintenance costs. FRP pipes are free from these pollution and are clean for a long time. At the same time, because of its smooth inner wall and excellent corrosion resistance, it will not cause scale and microbial growth, effectively guarantee water quality and maintain the stability of water resistance. But the traditional pipe still exist after water resistance increases and the surface fouling phenomenon.

- Q: What are the main points for the installation of FRP ducts?

- All you can think of public places, shopping malls, residential buildings, enterprises, institutions, etc., and so on, as long as the money, that can be installed

- Q: How can FRP tanks be connected to steel tubes?

- Glass tube and carbon steel pipe connection, at present, the most reliable way of connection is only flange connection, other such as on-site bonding, because the two kinds of material is not the same, the quality is not very stable after bonding!

Send your message to us

Composite API Hot Spring Pipe High Pressure GRE Pipes DN 40-300mm

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 1000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords