Color Printed Craft Paper Laminated with Plastic Film for Packing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100000 pc

- Supply Capability:

- 10000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Description of Color Printed Craft Paper Laminated with Plastic Film for Packing

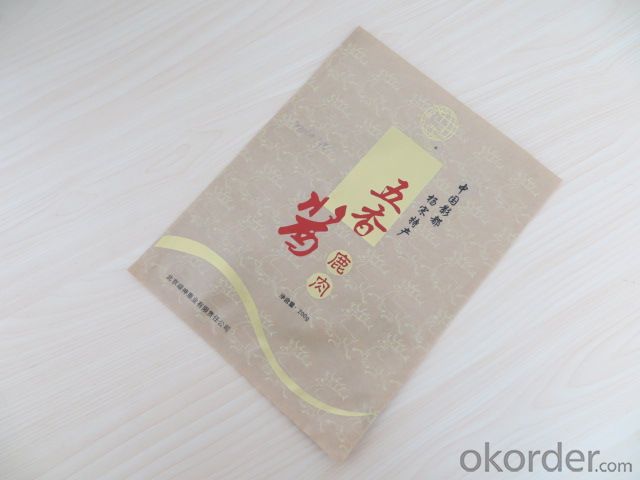

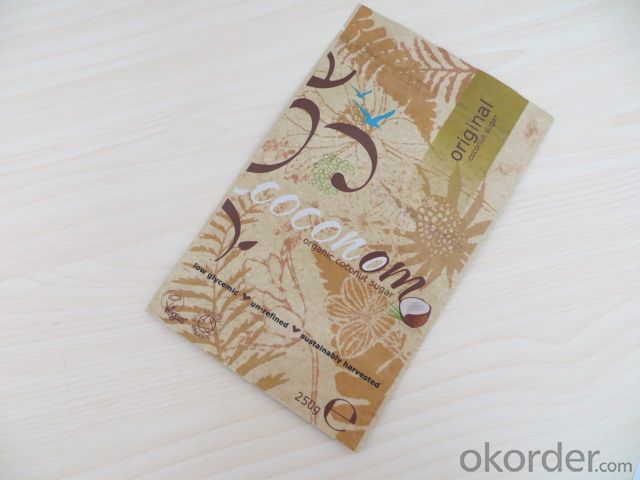

Color Printed Craft Paper Laminated with Plastic Film for Packing are processing with imported materials,we have introduced advanced equipment and high manufacturing technology into production lines and we have rich experience in producing plastic bag .can meet your needs by fulfilling your specification in a positive manner .High efficiency and speed are our working style .high quality and competitive price are our pursuit.

Color Printed Craft Paper Laminated with Plastic Film for Packing mainly used for packing food such as coffee, tea, snack, powder etc.

2. Main Features Color Printed Craft Paper Laminated with Plastic Film for Packing

Excellent quality control

Experienced factory produced

SGS passed

3. Color Printed Craft Paper Laminated with Plastic Film for Packing Used for Packing Photos:

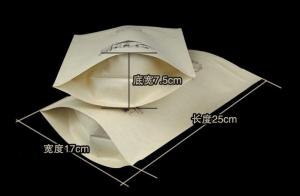

4. Color Printed Craft Paper Laminated with Plastic Film for Packing Specification:

1. Material: PE, LDPE,HDPE with Craft paper etc

2.Size:10*10000px or Customized

3.Thickness:10-200um

5.FAQ of Color Printed Craft Paper Laminated with Plastic Film for Packing

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of Plastic packing bags can supply you all kind of packing bags you wanted.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers. Commonly 7 to 10 working days can be served.

- Q: What products need plastic packing bags?

- Need to use plastic bags do not have too much garbage bags, food bags, beverage bags, commodity bags, clothing bags, plastic bags are closely related to human, as long as you want, we can use plastic bags for packaging, plastic just different ingredients. Because plastic bags are convenient to carry and relatively low cost, they are well known to people.

- Q: What are the advantages and disadvantages of OPP and CPP membranes? What kind of bags are they used for?

- CPP films have the characteristics of good transparency, high gloss, good stiffness, good moisture resistance, good heat resistance, and easy to heat sealing. CPP film is printed and bag made

- Q: How are food bags made out?

- Packaging design: This is based on the requirements of the food company to design the layout of the food packaging bag, that is, the pattern of food packaging bags. A good design layout of food packaging bags can improve the sales of products. After all, the first eye is still very important. This pattern is generally designed by the food company and then given to the manufacturer of the bags.

- Q: The shelf life of the package usually takes several forms

- Food soft packing materials mainly include polyethylene, polypropylene, polyester, polyamide and other polymer materials. These packing materials show great differences because of their molecular structure, forming process and additives. Therefore, for food manufacturers, choose a suitable packaging for their products is particularly important, otherwise there will be food safety issues.

- Q: Printing process of packaging bag

- For the surface or irregular surface can be used heat transfer, adhesion is good, not easy to fade, but requires a transfer equipment.Screen printing belongs to orifice plate printing. It is called four printing methods together with flat, convex and gravure printing. Hole printing includes transcription, mesh flower version, stencil printing and screen printing etc.. Printing the principle is: (a version of the base paper or other version of the film version of the ink can be made through holes) at the time of printing, through a certain pressure so that the ink to the substrate through the hole hole Edition (transfer paper, ceramics etc.) on the formation of images or text.

- Q: What's the packing of the air in the food package?

- Carbonated drinks are mostly filled with carbon dioxide gas CO2, and its own drinks are carbon dioxide ingredients in the majority, with CO2 replacement of the air, but also for the preservation of the product, to ensure the taste, but also improved the shelf life.In addition, some food packaging is filled with a certain proportion of mixed gas, may be O2+CO2+N2, N2+CO2, O2, +CO2. This is also based on the needs of different enterprises, different customers.

- Q: What material is the packing bag for pure milk, please?

- General milk packaging is basically Tetra Pak packaging or Kang Mei package, aluminum foil about 5% of the quality of the entire package, about 79% of the paper, polyethylene layer of about 16%. Because the aluminum foil, polyethylene layer and paper layer are bonded by hot pressing or adhesion, it is difficult to separate the layers. Learn1986 (in station contact TA) these two documents may be useful to you.

- Q: Which kind of transparent vacuum packing bag 16 wire and 24 wire?

- The so-called silk is a unit, a trace of =0.01mm, from this point of view, the bag is thicker, the more difficult to leak, so the 24 wire than the 19 wire better.

- Q: Is the color of cement packing bags related to cement?

- Portland ash cement, fly ash, silicate sleep and composite Portland cement -- black or blue.The cement packing bags shall clearly indicate the standards of implementation, cement varieties, codes, strength levels, producers' names, production licence marks (QS) and serial numbers, serial numbers, date of packing and net contents.

- Q: How about the material difference of food packaging bag?

- Reason: PE has better heat sealing property, which is easy to sealPA has better printability and is used in the outer layer to print beautiful picturesPVDC EVOH, good separation performance, prevent oxidation. The film closed light is good, not easy to see the light of the product is appropriate.Specific more professional, no longer introduce one by one

Send your message to us

Color Printed Craft Paper Laminated with Plastic Film for Packing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100000 pc

- Supply Capability:

- 10000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords