Coke breeze 10-30mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Structure of Metallurgical Coke of Coke breeze 10-30mm Description:

Coke is made by high temperature metallurgical coke for blast furnace smelting, casting and gasification. Occurring in the process of coking after recovery and purification of coke oven gas is a high calorific value of fuel, is an important industrial raw material in organic synthesis.

Analysis of coking coal supply and demand, to pay attention to the coke import and export situation in China.Due to the coke export prices and domestic price linkage, basically at the same time the quota also play a key role.

The report of inventory, also called "shadow inventory", refers to the global manufacturers, traders and consumers, hold inventory.Because the inventory not released regularly, so hard to count, typically measured in exchange of inventory.

2. Main Features of the Metallurgical Coke of Coke breeze 10-30mm :

• Quality assurance

• Mutual benefit

• Preferential price

• Various choice

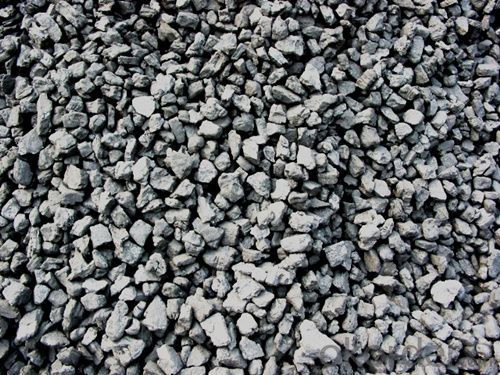

3. Metallurgical Coke of Coke breeze 10-30mm Images:

4. Metallurgical Coke of Coke breeze 10-30mm Specification:

Parameters | Guarantee | Rejection |

Total Moisture ( As received basis ) | 8% max | |

Ash ( dry basis ) | 12.5% max | > 13.5% |

Volatile Matter ( dry basis ) | 1.5% max | > 1.8% |

Sulphur ( dry basis ) | 0.70% max | > 0.80% |

Phosphorus ( dry basis ) | 0.020% max | > 0.025% |

Size 10-30 mm | 90% min | |

+30 mm | 5% max | > 8% |

-10 mm | 5% max | >8% |

5. FAQ

Consumption are the direct factors affect the price of coke, and with the development of coke industry is the important factors that affect consumption.The cost of production is the basis of the measure of commodity price level.

- Q: Various types of coal coke are the main test items

- If you need to test coal, caking index (G value), glial layer (X, Y) and other indicators, the index also includes the detection of more coal ash melting point (ash melting), hydrocarbon, the Hardgrove grindability index of coal, burning, swelling, activity, Oaxaca coal coal. Slag index.

- Q: What is the concept, relationship and difference between coke and coke? The main difference and contact, thank you

- 6, the horizontal type coke oven drying machine(7) gas purification circulating water.... supporting technology(8) dry cooling technology of interlayer water-cooled steam.(9) microcomputer precise dosing system

- Q: Coke is how to produce, what is its purpose?

- Natural coke. Coke can be obtained by high-temperature carbonization of coal:

- Q: What is cokeWhat applications are, what is the fire of Malachite copper

- Malachite is a kind of copper, copper smelting with coke burning malachite is under high temperature.

- Q: What are the main uses of coke

- A small smelting industry, used to produce calcium carbide, carbon disulfide, phosphorus etc.. In the iron and steel enterprises, coke powder is also used as sintering fuel. Coke can also be used as raw material for the preparation of raw materials for the synthesis of water gas. ??4, in order to make the blast furnace operation to achieve better technical and economic indicators, smelting coke (metallurgical coke) must have the appropriate chemical and physical properties, including the smelting process of thermal properties.

- Q: What is the amount of waste gas produced by a ton of coke burning

- Process for producing coke, coke oven gas and coking chemical products by thermal decomposition and coking.

- Q: Coke in the whole process of steelmaking in the end is what to do, just to provide heat or carbon and other substances into steel or iron?In the study of coal classification inside, one is divided into coking coal, coking coal and coke as main, and then you see is steel or iron coke must material. What is not clear. In the end, out of coal mining is mainly used to burn energy extraction, or said that coal like oil can be converted into other products, which is a coke can convert?

- It is necessary to add coke, pellet, sinter ore, ore and other materials into the blast furnace in a certain proportion, batch and sequence, and then to produce molten iron in the reducing atmosphere of the blast furnaceAfter the hot metal to steel in converter against the general converter, scrap also need to add a certain amount of used to balance the heat. Hot metal and scrap are added to the converter after the oxygen lance for oxygen operation, the oxidation of oxygen to carbon in liquid iron, silicon, manganese, phosphorus, sulfur and some non-metallic inclusions to form steel. Adding lime, dolomite, iron oxide and mine slag and coolant is needed in oxygen at the same time. After the completion of steel smelting in the tapping process according to different requirements with the corresponding iron alloy steel, after also refining process.

- Q: What does the M40% and M25% mean in the analysis of coke?

- (1) crushing strength (shatter strength): the ability of a certain particle size coal sample to fall under the condition of free fall.

- Q: How many degrees of coke ignition temperature can ignite coke

- The average specific heat capacity is 0.808kj/ (KGK) (100 DEG C), 1.465kj/ (KGK) (1000 DEG C);The thermal conductivity is 2.64kj/ (MHK) (room temperature), 6.91kg/ (MHK) (900 DEG C);Ignition temperature (450-650) in air;

- Q: What are the quality indicators of coke

- 2, the phosphorus in the coke: iron metallurgical coke coke content should be in the following 0.02 - 0.03%. 3, the ash content of coke: Coke Ash on the impact of the blast furnace smelting is very significant. Coke ash increased by 1%, coke consumption increased by 2 - 2.5%, therefore, the reduction of coke ash is very necessary. 4, volatile in coke: according to the volatile content of coke can determine the maturity of coke. Such as volatile content is greater than 1.5%, is said to produce coke; volatile less than 0.5 - 0.7%, it is said to be overdone, the general maturity of metallurgical coke volatile is divided into about 1%. 5, the moisture in the coke: water fluctuations will make the measurement of coke is not allowed, resulting in fluctuations in furnace conditions. In addition, the increase in the moisture content of Coke will make the M04 high, M10 is low, the drum index error. 6, the screening of coke composition: in the blast furnace coke particle size is also very important. In the past, the particle size of coke in our country is as follows: the coke size of large coke oven (1300 - 2000 square meters) is greater than 40 mm; the coke size of medium and small blast furnace is larger than 25 mm. However, some of the steel test shows that the coke particle size of 40 - 25 mm as well. Larger than 80 mm of coke to be whole, so that the particle size range. The coke block is uniform, the gap is large, the resistance is small, and the furnace condition runs well. Coke use: Shanxi sales all kinds of specifications of foundry coke, metallurgical coke, high sulfur coke trucks or wagons can transport

Send your message to us

Coke breeze 10-30mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords