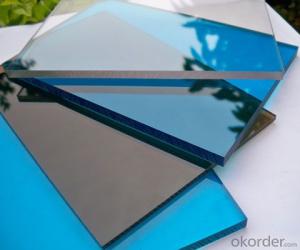

Clear Acrylic Sheets 1220*2440mm 3mm 5mm acrylic board

- Loading Port:

- SHANGHAI

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 300 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Acrylic is a synthetic plastic created by a chemical reaction between a catalyst and a monomer, resulting in a lightweight and transparent plastic product. Cast acrylic is made by pouring the liquid ingredients into a glass mold, where it hardens into a strong sheet. This is in contrast with extrusion, which pushes the liquid through an extruder and rollers to create a similar sheet. The process of casting creates a hard, sturdy, and uniform plastic sheet.

Product Name | Pure 100% Virgin Mitsubishi PMMA Cast Acrylic Sheet |

Material | 100% Virgin Mitsubishi MMA only |

Density | 1.2g/cm3 |

Thickness | 1.8-100mm |

Size | 1220*1830,1220x2440,2050x3050,1050x2050,etc |

Color | Clear, Opal, white, black, red, yellow, green, blue, pearl, brown, gray, purple,marble, glitter, translucent |

Package | Sheets covered by brown paper or PE film, and packed by exporting wood pallets. |

Guarantee | 10 years |

Capacity | 500 tons or 25 containers per month |

OEM | Color match and logo OEM are welcome |

Sample | Our sample are free, just freight by collect |

Delivery date | 15-20 days for 1x20ft container |

Test Report

Related Products

- Q: How to correctly identify the quality of pc sunshine board and pc durability plate method

- Pull the protective film to see the sheet. Particles or bubbles are relatively small or relatively small, indicating that the recovery of raw materials, but is a good back to the material, this board is the middle grade plate. Such as bubbles and particles more or larger, indicating that the poor raw material, this board is a low-grade plate. If the civilian particles or particles rarely, that the quality of the sun plate is very good, is ten years of quality.

- Q: What is the difference between a hollow board and a sunboard?

- But both have a lighting function, which sunshine board lighting performance and weather better and the lighting board is better acid and alkali resistance, not easy to be acid and alkali corrosion, the production process is not the same, the sun is a co-extruded, the production process Slightly more complicated. The lighting plate is connected to the tapping screw and must have a cover plate. Sun plate cold and heat deformation is large, easy to be self-tapping nail cut, so the sun plate in the self-tapping nail should open a larger hole. In the installation of lighting panels to consider the expansion of the lighting board.

- Q: PC sun panels and color steel plate how to bond

- In fact, with a little bit of weather resistance can be plastic, completely unnecessary Bolts, try HTACK7, you can use self-tapping or bolts, and then neutral sealant;

- Q: How much of the installation of the sun board installation of a square meter

- An effective space must be provided in the connection profile or in the mounting groove of the frame so that the plate is subject to expansion and load displacement. The linear thermal expansion coefficient of the hollow sun plate is 7 × 10m / mk, that is, the temperature of each 1 ℃, 1m × 1m board along the length of the expansion of 0.075mm, the user should be based on the location of the four quarters of the temperature difference between the calculation of the installation gap data: Such as the northern region, the maximum temperature of 40 ℃, the minimum temperature of -30 ℃, 1m × 1m of the plate to install the gap is 0.07 × 70 = 4.9mm

- Q: Sunny plate that is a transparent that I want to use the home screen 4mm thickness can be about how much a square

- Screen, then you can use matte endurance board or particle stamina board, more beautiful. 4mm thickness is enough. Can be strong The quality of the general should be much cheaper. Home with the proposal to buy that, ten years warranty. Recommended goods-PC patience board, the domestic material this one more famous.

- Q: PC sunshine board, what material, what kind of good

- If you want to use their own cost-effective relatively high we can choose 10mm quality better, this kind of sunshine board in the normal situation is to allow people not often walk in the above. But for 8mm or 6mm sun panels, if people go in the above or want to shelf life for a long time there may be a safe use of hidden dangers.

- Q: What is the difference between sun panels and lighting panels?

- Material composition description Xining PC sun panels are made of polycarbonate on the surface of a layer of 50um UV UV layer, hollow structure extrusion molding of high-performance lighting materials. Is the most excellent performance of engineering plastics, which has a light, flame retardant, high impact strength, high transmittance, high stability, easy to bend and other characteristics. And is an energy-saving, environmentally friendly materials. Is the preferred material for making lighting materials. FRP lighting board is glass fiber reinforced polyester (FRP lighting board), commonly known as FRP, also known as transparent tile, which mainly by the film, unsaturated resin and glass fiber composition. Frp main material is unsaturated resin, its high strength, flammable, the resin itself is easy to decompose above 50 ℃, poor stability. Resin is chemically synthesized, using styrene solvent, toxic.

- Q: Can sunscreen be insulated at night? PC sunshine board insulation performance how?

- In addition, the thicker the thickness of the polycarbonate PC solar panels, the more layers, the better the insulation performance, but not necessarily the thicker the better, because the PC sheet with the thickness increases, structural complexity, price increases, or to Choose the right one. PC sunshine board during the day cold, night insulation, suitable for greenhouses and other greenhouse lighting insulation use, PC sun panels up to 49% insulation.

- Q: Company pc sunshine board how to solve the problem

- Buy special mosaic aluminum parts, the higher cost, suitable for municipal works, large-scale light shade shade project.

- Q: Can the sun board cover the bedroom?

- is allowed. Insulation: Insulation performance is 40% to 60% higher than glass of the same thickness. Fire resistance: to GB8624 flame retardant level (B1 level) standard. Light weight: the proportion of only the general glass 1/12, and not easy to crush, handling installation time and effort, especially for tall buildings. Easy processing: bending radius up to 175 times the thickness of the plate, suitable for processing a variety of shapes. Greenhouse board energy saving: sun panels have lower than ordinary glass and other plastic thermal conductivity (K value), so that greatly reduce the heat loss, for heating equipment, construction, environmentally friendly materials. Greenhouse Anti-condensation: Under normal circumstances, when the outdoor temperature is 0 ℃, the indoor temperature is 23 ℃, as long as the indoor humidity is less than 80%, the surface of the material will not be condensed.

Send your message to us

Clear Acrylic Sheets 1220*2440mm 3mm 5mm acrylic board

- Loading Port:

- SHANGHAI

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 300 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords