Cement Foaming Agent A New Generation For Concrerte

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 kg

- Supply Capability:

- 50000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Cement Foaming Agent

(MNC-FP)

Description

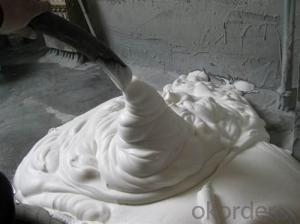

MNC-FP is a new generation multifunctional foaming agent condensated from high molecular components. It features bigger foaming capacity, high fineness and stability.

Application

MNC-FP is mainly applied in organic and inorganic products where foaming and low density is required, such as foaming concrete, intermediate wall board made of foaming concrete, gypsum slat, heat insulation materials made of foaming silicate and foaming fly ash.

Features & Benefits

1. Reduced density: the density of foamed cement is equivalent to 1/2~1/5 of that of common cement, which shall relieve the bearing load of the structure.

2. Higher heat insulation: 20 to 30 times higher than common cement.

3. Improved strength: the compressive strength is higher than 0.25Mpa, and foamed cement of different strength grade can be produced as per technical requirements.

4. Good sound insulation: the foamed cement has large quantities of bubbles in homogeneous distribution, and its sound absorption is five times higher than that of common cement.

5. Integrity: the foamed cement has sufficient absorption with ground due to the good binding property of concrete integrity.

6. Pro-environment: the foamed cement is nontoxic, odorless, non-volatile and nonflammable.

7. Low dosage and cost-efficiency.

Test Data Sheet

Uses and Dosages

1. It can be applied directly at a recommended dosage of 0.8% to 1.0% by weight of cementitious materials. It can also be dissolved into water 25~50 times of its quantity and fully mixed before use.

2. Pour the solution into the container of the foaming machine.

3. Prepare cementitious materials based on designed bulk density.

4. Switch on the foaming machine, and spay the ready to use foams into mixer till designed bulk density is achieved.

5. Please follow practices and techniques related to making a target product.

Package, Storage and Handling

1. It's packed in 36kg/bag, 3kg per small sized bag within.

2. It should be stored in a dry and cool place. Its shelf life is 2 years.

Send your message to us

Cement Foaming Agent A New Generation For Concrerte

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 kg

- Supply Capability:

- 50000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords