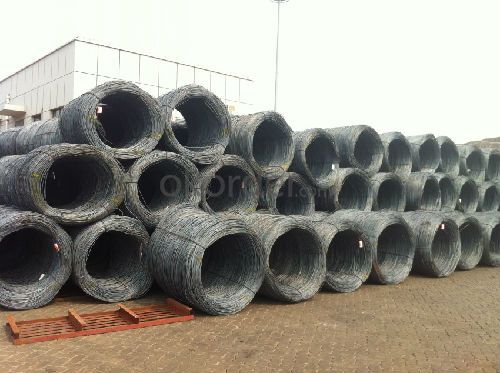

Carbon Steel Hot Rolled Wire Rod in Coil

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Wire Rod at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

After hot-rolled the products shaped into coil and delivery as finished product, including round, square, rectangular, hexagonal and so on. Since most of the products are round, it is generally called wire rod. Carbon steel wire rod is widely used in construction and manufacturing. Carbon steel wire rod is mainly used for reinforcement of reinforced concrete and welded structure or reprocessed (roberts , nail, etc.) materials, especially used to produce wire drawing, welding electrode, nails, spring, electronic, precise machinery parts and so on.

Product Advantages:

OKorder's Wire Rod are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Steel Grade: Q195/235, SAE1006-1018B Standard: ASTM, GB

Diameter: 5.5mm, 6.5mm, 7mm,8mm,9mm,10mm,12mm,14mm

Type: in coil, coil weight around 2MT Alloy or Not: Alloy

Surface: round, no twisted, light and smooth Chemical Composition: (Please kindly find our chemistry of our material based on Q195、Q235A and Q235B as below for your information)

Grade | Chemical Composition (%) | |||||

C | Mn | S | P | Si | B | |

SAE1008B | 0.10max | 0.32max | 0.045max | 0.040max | 0.30max | 0.0008min |

Mechanical properties | ||||||

Yield strength(N/mm2) | Tensile strength(N/mm2) | Elongation (%) | ||||

≥195 | 350-380 | ≥32 | ||||

Note:

1. Our products are produced according to national standard (GB), if not, supply according to national standards (GB) or agreement as customer required.

2. Other Grade and Standard carbon steel wire rod we can supply:

Grade: H08A, 30MnSi, 62B-82B

Standard: AISI, BS, JIS, DIN

The Minimum Order Quantity of these products is high, and need to be confirmed.

3. We can not only supply carbon steel wire rod; if you need anything about building materials, please contact us.

4. Please send us your detail specifications when inquire. We will reply to you as soon as possible. We sincerely hope we can establish a long stable business relationship.

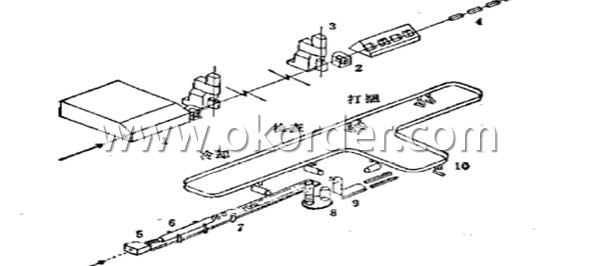

1-Furnace 2-Roughing Mill 3-High-speed Finishing Mill 4-Water-cooled Device 5-Coiling Device

6-Cooling Device 7-Chain Conveyer 8-Spool Collecting Device 9-Spool Down Device 10-Hook Conveyer

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Images:

- Q: What are the main factors affecting the market forecasts of steel wire rod?

- The main factors affecting the market forecasts of steel wire rod include global economic conditions, demand from end-use industries such as construction and automotive, raw material prices, government policies and regulations, technological advancements, and competition from alternative materials.

- Q: How is the toughness of steel wire rod determined?

- The toughness of steel wire rod is determined through various mechanical tests. One common test used to evaluate its toughness is the Charpy impact test. In this test, a notched sample of the wire rod is placed in a pendulum impact machine, and a swinging pendulum strikes and breaks the sample. The energy absorbed by the sample during the fracture is measured. The higher the energy absorbed, the tougher the steel wire rod. Another test commonly used is the tensile test, which measures the resistance of the wire rod to stretching or pulling forces. During this test, a sample is pulled until it breaks, and the maximum stress it can withstand is recorded. The area under the stress-strain curve obtained from the test provides an indication of the toughness of the material. Additionally, other tests such as hardness testing, fatigue testing, and fracture toughness testing can also be conducted to assess the toughness of steel wire rod. These tests provide valuable information about the material's ability to withstand external forces, resist deformation, and prevent failure. Overall, the toughness of steel wire rod is determined through a combination of different mechanical tests that evaluate its ability to absorb energy, resist deformation, and withstand external forces.

- Q: What are the different types of steel wire rod coating thicknesses?

- Depending on the specific application and requirements, there are various options available for coating thicknesses in steel wire rods. Some commonly used coating thicknesses are as follows: 1. Light Coating: This coating type involves the application of a thin layer of protective material on the steel wire rod. It offers minimal protection against corrosion and is suitable for environments or conditions that are not too harsh. 2. Medium Coating: With a thickness greater than that of a light coating, the medium coating provides a moderate level of protection against corrosion and other environmental factors. It is often chosen for applications where the wire rod may be exposed to moderate levels of moisture, chemicals, or abrasion. 3. Heavy Coating: A thicker layer of protective material is applied to the steel wire rod in this case. The heavy coating offers enhanced protection against corrosion, abrasion, and other harsh conditions. It is commonly used in applications where the wire rod will be exposed to extreme environments, such as marine or industrial settings. 4. Galvanized Coating: This type of coating involves the application of a layer of zinc on the steel wire rod. It provides excellent protection against corrosion and is commonly used in outdoor applications where the wire rod will be exposed to moisture and other environmental factors. When selecting the appropriate coating thickness for steel wire rod, it is essential to consider the specific requirements of the application. Factors such as the expected level of exposure to moisture, chemicals, abrasion, and temperature variations should be taken into account to ensure optimal performance and longevity of the wire rod.

- Q: What are the different heat treatment processes used for steel wire rod?

- The different heat treatment processes used for steel wire rod include annealing, quenching and tempering, and normalizing. Annealing involves heating the steel to a specific temperature and then gradually cooling it, resulting in improved ductility and toughness. Quenching and tempering involves rapid cooling of the steel followed by reheating and then slow cooling, enhancing the hardness and strength of the wire rod. Normalizing involves heating the steel to a temperature above its critical point, followed by air cooling, resulting in improved structural uniformity and strength.

- Q: How are steel wire rods packaged and shipped?

- Steel wire rods are typically packaged and shipped in coils or bundles. The rods are tightly wound into coils, secured with steel straps or wire ties, and then wrapped in protective materials such as plastic or paper. These coils are then loaded onto pallets or into crates for transportation. Alternatively, smaller diameter rods may be bundled together with steel straps or wire ties and packaged in wooden crates or steel frames. Once packaged, the steel wire rods are shipped using various modes of transportation, including trucks, trains, and ships, depending on the distance and destination.

- Q: What are the advantages of using steel wire rod compared to other materials?

- There are several advantages of using steel wire rod compared to other materials. Firstly, steel wire rod offers high strength and durability, making it suitable for various applications where a strong material is required. Secondly, steel wire rod has excellent flexibility, allowing it to be easily bent or shaped without breaking, which makes it ideal for applications that require flexibility, such as in construction or manufacturing. Additionally, steel wire rod has good corrosion resistance, ensuring its longevity and suitability for outdoor or corrosive environments. Lastly, steel wire rod is widely available and cost-effective, making it a cost-efficient choice for many industries.

- Q: Is there any difference between wire rod and round steel in steel?

- Main application: Pu wire is mainly used for building reinforced concrete structure for reinforcing bars, and it can also be made of cold drawn steel wire for strapping and so on.

- Q: What are the different types of testing conducted on steel wire rod?

- The different types of testing conducted on steel wire rods include dimensional inspection, chemical composition analysis, mechanical property testing, surface quality examination, and non-destructive testing such as ultrasonic testing, magnetic particle inspection, and eddy current testing.

- Q: What are the different surface lubricants used for steel wire rod?

- There are several different surface lubricants that are commonly used for steel wire rod. These lubricants are applied to the surface of the wire rod to reduce friction and improve the drawing process. One commonly used lubricant is a water-based emulsion. This type of lubricant contains a mixture of water and oil, along with additives to enhance its lubricating properties. Water-based emulsions are often used for drawing operations that require high-speed and high efficiency. Another type of lubricant used for steel wire rod is a dry lubricant. Dry lubricants are typically powder-based and are applied to the surface of the wire rod in dry form. These lubricants can provide excellent lubrication properties while minimizing the potential for contamination or mess. Some steel wire rod manufacturers also use oil-based lubricants. These lubricants are typically petroleum-based and can provide good lubrication properties for a wide range of drawing operations. However, oil-based lubricants may require additional cleaning steps to remove any residual oil from the wire rod surface. In addition to these commonly used lubricants, there are also specialty lubricants available for specific applications. For example, some wire rod manufacturers may use graphite-based lubricants for drawing operations that require high temperatures or extreme pressures. Overall, the choice of surface lubricant for steel wire rod will depend on factors such as the specific drawing operation, the desired level of lubrication, and any specific requirements or restrictions for the end product.

- Q: What are the main factors influencing the choice of steel wire rod surface finish?

- When determining the appropriate surface finish for a steel wire rod, several factors come into play, each playing a significant role. The intended use of the wire rod is one of the main factors to consider. Different surface finishes offer varying levels of corrosion resistance, lubricity, and adhesion properties. These properties are crucial in determining whether the wire rod is suitable for a specific application. For instance, in a corrosive environment, a surface finish that provides enhanced resistance to rust and oxidation may be necessary. The desired aesthetic appearance is another factor that influences the choice of surface finish. Industries like automotive or consumer goods may have specific requirements for the visual appeal of the wire rod. In such cases, finishes that offer a smooth, polished, or decorative appearance may be preferred. The mechanical properties required for the wire rod's application also play a role in determining the surface finish. Some finishes, such as bright or polished surfaces, can improve the wire rod's yield strength, ductility, and fatigue resistance. These properties are vital in applications involving high-stress conditions or requiring flexibility and durability. Cost considerations are also important when selecting the surface finish. Some finishes require additional processing steps, like pickling, coating, or electroplating, which can increase the overall cost of the wire rod. Therefore, it is essential to balance the desired surface finish with the cost-effectiveness of the manufacturing process. Lastly, environmental and regulatory factors can influence the choice of surface finish. Certain finishes may contain hazardous substances or require specific disposal methods, impacting the environmental footprint of wire rod production. Compliance with industry standards and regulations is crucial to ensure the safety and sustainability of the finished product. In conclusion, the choice of steel wire rod surface finish is influenced by factors such as intended use, aesthetic requirements, mechanical properties, cost considerations, and environmental considerations. By carefully considering these factors, manufacturers can select the most appropriate surface finish that aligns with the specific requirements of the application and ensures optimal performance and quality of the wire rod.

Send your message to us

Carbon Steel Hot Rolled Wire Rod in Coil

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords