Bus Ribbon -Manual Welding

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure

We produce custom engineered solar tabbing and bus wire helping to attain the highest efficiencies possible for each unique module design. Our Research and Development team can assist you with your needs evaluation and our world-wide manufacturing facilities are strategically located for large volume production.

Feature

The Flux should be compounded and processed in such a manner as to be uniform in quality and should be free from deleterious material and other details that will after life serviceability or appearance.

Cold Rolling Mills for manufacturing Photovoltaic (PV) Ribbon:

Cold Rolling Mills for manufacturing Photovoltaic Ribbon

This machine is for making Bare flat copper conductors which is using PV Ribbon Wire , Tinned plated flat copper conductors which is using FFC or materials and it was designed to make the best quality products with high productivity as well as easy to control.

Machine capacity

Tinned plated flat copper conductors which is using FFC

Images

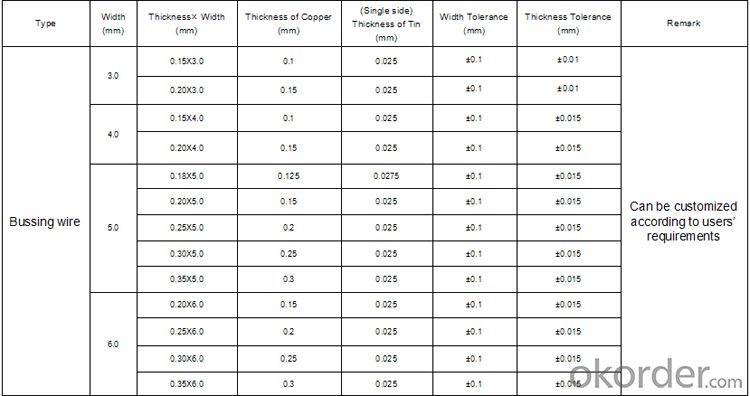

Specifications

FAQ

Q:How to guarantee the quality of the products?

A:We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

Q:Can we visit your factory?

A:Surely, I will arrange the trip basing on your business schedule.

Q:Which payment terms can you accept?

A:T/T,L/C,Moneygram,Paypal are available for us.

- Q: Are there any safety measures or precautions to consider when using a solar pump?

- When using a solar pump, it is important to consider various safety measures and precautions. These are: 1. Electrical Safety: Solar pumps have the potential to generate electricity, so it is crucial to adhere to electrical safety guidelines. Ensure that all wiring and connections are adequately insulated and protected from water or physical damage. Use a circuit breaker or disconnect switch to cut off power during maintenance or repairs. 2. Water Safety: When working with a solar pump that draws water from a well or pond, be cautious of possible water contamination. Utilize an appropriate filtration system to remove impurities and regularly clean and disinfect the water source. Additionally, make sure the pump is properly sealed to prevent water from entering critical components. 3. Overheating Prevention: Solar pumps rely on sunlight to generate power, and excessive heat can decrease their efficiency or cause damage. Install the pump in a shaded area or use a protective cover to shield it from direct sunlight, particularly during peak hours. Regularly check for signs of overheating, such as melted wires or burnt odors. 4. Maintenance and Inspection: Regular maintenance and inspections are vital to ensure the safe and efficient operation of a solar pump. Adhere to the manufacturer's guidelines for routine checks, cleaning, and lubrication. Inspect the pump's components, including panels, wiring, and valves, for any indications of wear or damage. Address any issues promptly to prevent further complications. 5. Installation and Mounting: When installing a solar pump, carefully follow the manufacturer's instructions and guidelines. Ensure that the pump is securely mounted to prevent accidental falls or damage. Use appropriate mounting brackets or structures that can withstand the weight and environmental conditions. 6. Training and Education: It is essential to have adequate knowledge and training regarding the operation of solar pumps. Understand the specific features, controls, and safety precautions of the pump. If necessary, seek professional assistance or training to ensure safe and effective usage. By adhering to these safety measures and precautions, users can minimize the risk of accidents, optimize the performance of their solar pump, and ensure its longevity.

- Q: How do solar vacuum tubes perform in areas with high levels of volcanic ash?

- Solar vacuum tubes may not perform optimally in areas with high levels of volcanic ash. The ash can potentially obstruct the sunlight from reaching the tubes, reducing their efficiency in converting solar energy into heat. Regular cleaning and maintenance would be necessary to ensure their proper functioning in such environments.

- Q: Can a solar inverter be used with a solar-powered agriculture system?

- Yes, a solar inverter can be used with a solar-powered agriculture system. A solar inverter is an essential component that converts the direct current (DC) electricity generated by solar panels into alternating current (AC) electricity, which is compatible with most electrical appliances and equipment. In the context of a solar-powered agriculture system, a solar inverter would be necessary to convert the electricity produced by the solar panels into the appropriate form for powering agricultural machinery, irrigation systems, or any other electrical needs on the farm.

- Q: Solar vacuum tube bad effect

- The vacuum tube is easy to break. Convenient or let the more professional to help you change it.

- Q: What is the role of solar-powered water purification systems in providing clean drinking water?

- Solar-powered water purification systems play a crucial role in providing clean drinking water by harnessing the energy of the sun to remove harmful contaminants and pathogens from water sources. These systems use solar panels to generate electricity, which powers the purification process, making them environmentally friendly and cost-effective. They are especially valuable in remote or off-grid areas where access to clean water is limited. Additionally, solar-powered water purification systems are easy to maintain, making them a sustainable solution for ensuring clean and safe drinking water for communities worldwide.

- Q: How does the size of a solar panel affect the performance of a solar pump?

- The size of a solar panel directly affects the performance of a solar pump. A larger solar panel can generate more electricity, which in turn provides more power to the pump. This leads to increased water flow and higher efficiency, allowing the pump to operate more effectively, especially in low-light conditions. Additionally, a larger panel can also store excess energy in batteries, ensuring continuous operation even during cloudy periods or at night.

- Q: Can a solar controller be used with a generator as a backup power source?

- Yes, a solar controller can be used with a generator as a backup power source. The solar controller regulates and manages the flow of energy from the solar panels to the battery bank. When the solar panels are not generating enough power, the solar controller can automatically switch to the generator as a backup source to charge the batteries. This ensures a continuous power supply even when solar energy is insufficient.

- Q: Do solar lights have a built-in dusk-to-dawn sensor?

- Yes, most solar lights have a built-in dusk-to-dawn sensor. This sensor allows the lights to automatically turn on at dusk and off at dawn, conserving energy and providing convenience.

- Q: Can solar collectors be used in automotive manufacturing?

- Solar collectors have the potential to be utilized in the automotive manufacturing sector. These devices have the ability to capture sunlight and convert it into usable energy, typically in the form of heat or electricity. Within the context of automotive manufacturing, solar collectors can provide renewable energy for various processes and operations. One way in which solar collectors can be applied in automotive manufacturing is by generating electricity. Large photovoltaic arrays can be installed on the roofs or surrounding areas of automotive manufacturing facilities, allowing them to harness solar energy and convert it into electrical power. This generated electricity can then be used to operate equipment and machinery in the manufacturing process, reducing reliance on traditional energy sources and minimizing carbon emissions. Solar collectors can also be utilized for heating purposes in automotive manufacturing. By using solar thermal collectors, sunlight can be captured and converted into heat. This heat can then be used for a variety of heating applications, including space heating, water heating, or even heating specific manufacturing processes. Incorporating solar collectors for heating purposes can help reduce the consumption of fossil fuels or electricity, resulting in cost savings and positive environmental impacts. Furthermore, solar collectors can be integrated into the design of electric vehicles (EVs) themselves. By installing solar panels on the roofs or other areas of EVs, sunlight can be captured and converted into electricity. This electricity can then be used to power auxiliary systems within the vehicle. While the electricity generated from these on-board solar collectors may not be sufficient to fully power the vehicle, it can help decrease the energy consumption from the main battery and increase the overall efficiency of the EV. To summarize, solar collectors offer a sustainable and renewable energy solution for the automotive industry. Whether it is through generating electricity for manufacturing processes, providing heat for various applications, or integrating into electric vehicles, solar collectors have the potential to play a significant role in automotive manufacturing.

- Q: How long does it take to recoup the cost of installing solar collectors?

- The time it takes to recoup the cost of installing solar collectors can vary depending on several factors such as the initial cost of the installation, the amount of energy saved or generated, and the local energy prices. However, on average, it usually takes between 5 to 10 years to recoup the cost of installing solar collectors through energy savings.

Send your message to us

Bus Ribbon -Manual Welding

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords