Buidling Construction Hoist Single Cage SC120

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Building Hoist Description

Condition: New

Application: Construction

Payload(kg):1200

Lifting Speed(m/min):0~60

Motor Power(kw): 3*11

Safety Device: SAJ30-1.4

Cage: Single

Counterweight: No

Certification: CE,ISO

Place of Origin: China(Mainland)

Model Number: Type:SC120

Packaging & Delivery of Building Hoist

Packaging Detail: Nude package

Delivery Detail: 25-30days

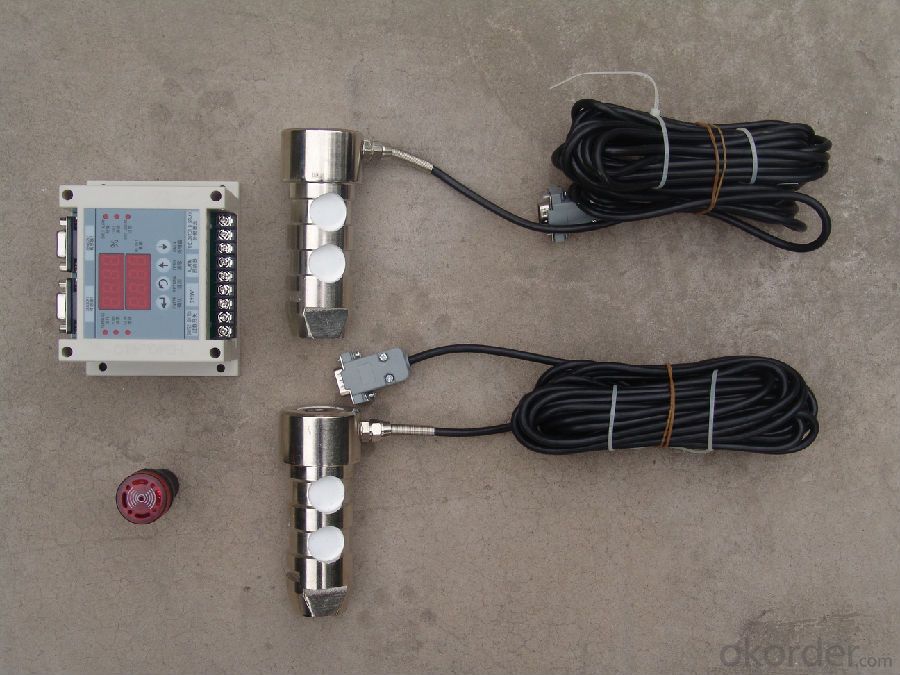

Building Hoist Images

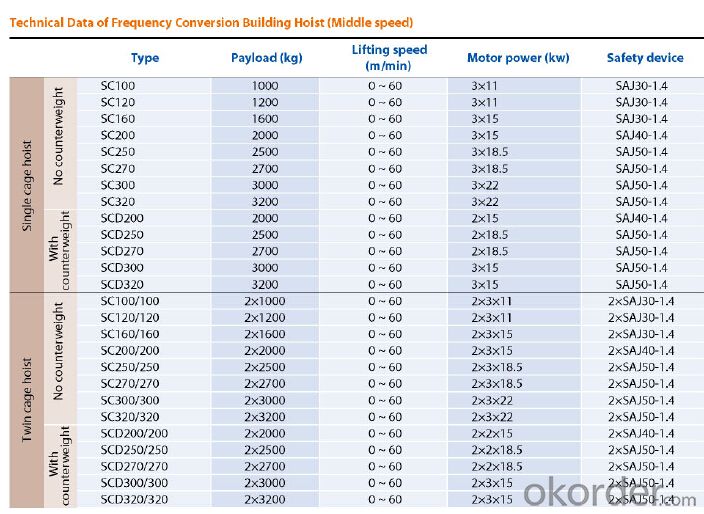

Building Hoist Specifiction

FAQ of Building Hoist

Q: What is the building hoist main purpose?

A: Building hoist equipped with double or single cabin to transport the materials and labors up and down. It's the ideal

construction equipment for vertical transportation in the field of construction.

Q: What is the main structure of building hoist?

A: The P/M construction hoist mainly contains metal structure, driving system, electrical control system, cable guide &

protection system, electrical top crane and safety device.

Q: What is the meaning of the building hoist’s code?

A: Take SC200/200 for example: “SC” stands for rack and pinion hoist, “200/200” stands for double cage and capacity

is 2 tons per cage. “SC200” stands for single cage and capacity is 2 tons.

- Q: Is it possible to utilize a building hoist for lifting materials during demolition projects?

- <p>While a building hoist is typically designed for construction purposes to lift materials and personnel, it is not advisable to use it for demolition work. Demolition involves hazardous conditions with falling debris and unstable structures, which can compromise the safety and integrity of the hoist. Instead, specialized equipment like wrecking balls, hydraulic shears, and cranes are more suitable for demolition tasks. These are engineered to handle the heavy loads and unpredictable conditions associated with breaking down structures safely.</p>

- Q: This question asks if a building hoist can be utilized in both commercial and residential settings.

- <p>Yes, a building hoist can be used for both commercial and residential purposes. These hoists are designed to lift materials and workers to various levels of a building under construction. In commercial settings, they are often used in high-rise buildings, while in residential construction, they are used for multi-story homes or apartment complexes. However, the specific type and capacity of the hoist should be chosen based on the project's requirements and safety regulations must be strictly adhered to in both types of construction.</p>

- Q: This question asks about the process of installing a building hoist, a piece of equipment used in construction to lift materials and personnel.

- <p>Installing a building hoist involves several steps: 1) Site preparation, ensuring the area is level and stable. 2) Unpacking and inspection of the hoist components. 3) Assembling the hoist tower, starting with the base and working upwards. 4) Installing the drive mechanism and control panel. 5) Rigging the hoist cables and safety devices. 6) Conducting a thorough inspection and testing the hoist to ensure it operates safely. 7) Obtaining any necessary permits and approvals. 8) Training operators on the safe use of the hoist. Always follow the manufacturer's instructions and local regulations when installing a building hoist.</p>

- Q: Is it possible to utilize a building hoist for the purpose of lifting large vehicles?

- <p>Yes, a building hoist can be used to lift large vehicles, but it requires a hoist specifically designed and rated for such heavy loads. It's crucial to ensure that the hoist has the necessary capacity and safety features to handle the weight of the vehicle. Additionally, the operation must be conducted by trained professionals following strict safety protocols to prevent accidents. It's also important to check local regulations and guidelines for lifting operations involving heavy machinery or vehicles.</p>

- Q: This question asks for a comparison between lifting equipment used in indoor settings versus those used outdoors, focusing on their differences.

- <p>Indoor lifting equipment is designed for controlled environments, often smaller and more precise, with features like electric chain hoists or jib cranes. They are typically quieter, require less maintenance, and are suitable for tasks like assembly, manufacturing, and warehouse operations. Outdoor lifting equipment, such as gantry cranes or mobile cranes, is built to withstand harsh weather conditions, has higher load capacities, and is often used for construction, shipping, and heavy industry. These are more robust, may require more maintenance, and are designed for larger, heavier loads over uneven terrain.</p>

- Q: This question asks for measures to protect lifting equipment from damage during its operation.

- <p>To prevent damage to lifting equipment during operation, ensure regular maintenance and inspection are conducted to check for wear and tear. Adhere to the equipment's load limits and never exceed them. Use appropriate lifting techniques and ensure the load is balanced. Keep the equipment clean and free from debris. Train operators thoroughly on safe operating procedures. Avoid sudden starts or stops, and ensure all safety features and guards are in place and functioning correctly. Regularly check cables, hooks, and other critical components for any signs of damage. Always follow the manufacturer's guidelines and industry safety standards.</p>

- Q: This question asks for a comparison of various types of electric building hoists, highlighting their unique features and differences.

- <p>Electric building hoists come in various types, each designed for specific applications. The main differences lie in their capacity, lifting speed, control systems, and construction. For instance, worm gear hoists are compact and offer precise control, suitable for light to medium-duty applications. Chain hoists are versatile with higher speeds and are ideal for general lifting tasks. Electric wire rope hoists are powerful and designed for heavy-duty lifting, often used in construction and industrial settings. Variable frequency drives in hoists allow for speed control, enhancing safety and efficiency. Each type has its operational advantages and limitations, making the choice dependent on the specific lifting requirements and environmental conditions.</p>

- Q: Describe the key differences between electric and manual building hoists.

- <p>Electric building hoists are powered by electricity and can lift heavy loads quickly and efficiently. They are automated, reducing manual labor and increasing productivity. On the other hand, manual hoists require human effort to operate, making them slower and less efficient. They are less costly but demand more physical labor, which can lead to fatigue and potential accidents. Electric hoists are suitable for large-scale construction projects, while manual hoists are often used in smaller, more confined spaces where electricity might not be readily available or where the load is not excessively heavy.</p>

- Q: This question asks whether a building hoist can be utilized for lifting various kinds of objects.

- <p>Yes, a building hoist can be used for lifting multiple types of objects. It is designed to handle a variety of materials, including construction materials, tools, and equipment. The hoist's capacity and design may vary, allowing it to accommodate different weights and sizes. However, it is crucial to ensure that the hoist's lifting capacity is not exceeded and that the objects are secured properly to prevent accidents. Always refer to the manufacturer's guidelines for specific weight limits and safety procedures.</p>

- Q: This question asks if it is permissible to use a building hoist for the purpose of lifting people.

- <p>No, a building hoist should not be used for lifting people. Building hoists are designed for the transportation of materials and equipment during construction, not for carrying personnel. Using a building hoist to lift people is dangerous and against safety regulations. It poses significant risks, including falls and equipment malfunctions, which can lead to serious injuries or fatalities. Always use designated personnel lifts or other safe methods for moving people in construction settings.</p>

Send your message to us

Buidling Construction Hoist Single Cage SC120

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords