Buidling Construction Hoist SC100 1000KG

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Building Hoist Description

Condition: New

Application: Construction

Payload(kg):1000

Lifting Speed(m/min):0~60

Motor Power(kw): 3*11

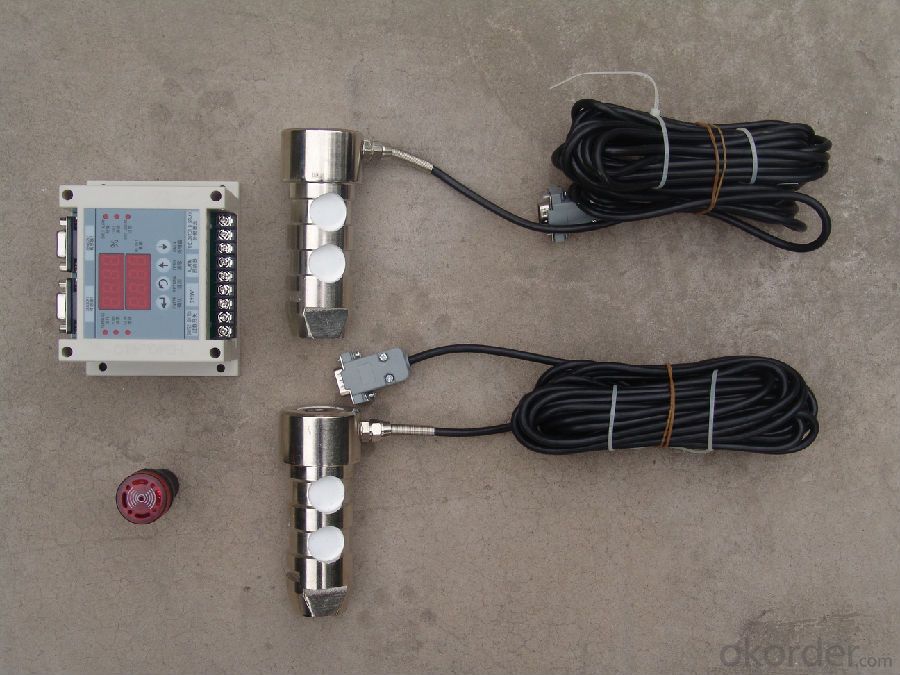

Safety Device: SAJ30-1.4

Cage: Single

Counterweight: No

Certification: CE,ISO

Place of Origin: China(Mainland)

Model Number: Type:SC100

Packaging & Delivery of Building Hoist

Packaging Detail: Nude package

Delivery Detail: 25-30days

Building Hoist Images

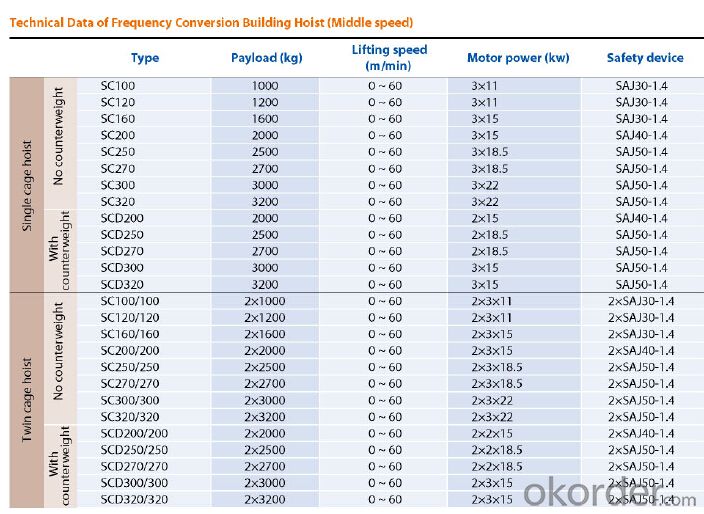

Building Hoist Specifiction

FAQ of Building Hoist

Q: What is the building hoist main purpose?

A: Building hoist equipped with double or single cabin to transport the materials and labors up and down. It's the ideal

construction equipment for vertical transportation in the field of construction.

Q: What is the main structure of building hoist?

A: The P/M construction hoist mainly contains metal structure, driving system, electrical control system, cable guide &

protection system, electrical top crane and safety device.

Q: What is the meaning of the building hoist’s code?

A: Take SC200/200 for example: “SC” stands for rack and pinion hoist, “200/200” stands for double cage and capacity

is 2 tons per cage. “SC200” stands for single cage and capacity is 2 tons.

- Q: Does the misuse or incorrect use of lifting equipment pose a risk of injury to workers?

- <p>Yes, improper or incorrect use of lifting equipment can cause serious injury to workers. This can include accidents such as dropping loads, which can lead to crushing injuries or being struck by falling objects. Additionally, improper lifting techniques can lead to musculoskeletal injuries, such as back strains or sprains. It's crucial for workers to be trained in the safe operation of lifting equipment and to follow all safety protocols to minimize the risk of injury.</p>

- Q: What are the primary parts that make up a building hoist system?

- <p>The main components of a building hoist include the hoist machine, which is the driving mechanism; the hoist shaft, a vertical structure that houses the hoist; the lifting platform or cage, which carries materials and personnel; the mast or tower, providing support and stability; the counterweight, which balances the load; safety devices such as limit switches and brakes; the control system for operation; and the electrical system that powers the hoist. Additionally, there are guide rails, cables, and buffers that ensure smooth and safe operation.</p>

- Q: The construction elevator can only go up can't come down what happened

- Does the motor have electricity when it falls? Look at the switch and the line first, then check the controller.

- Q: The question asks about the typical duration a building hoist can function before needing replacement or significant repair.

- <p>The lifespan of a building hoist can vary significantly based on factors such as usage frequency, maintenance, and the quality of the hoist itself. Generally, with proper care and regular maintenance, a building hoist can last anywhere from 10 to 20 years. However, heavy usage and inadequate maintenance can shorten this lifespan, while some high-quality hoists may exceed the average lifespan with fewer issues.</p>

- Q: Is it possible for a single lifting device to simultaneously lift multiple objects with varying weights?

- <p>Yes, a single lifting device can be used to lift multiple objects at once with different weights, provided the total weight does not exceed the device's lifting capacity. The device must be designed to handle the combined weight and ensure even distribution of the load. Safety measures and proper securing of the objects are crucial to prevent accidents. It's important to follow the manufacturer's guidelines and never exceed the maximum load capacity to avoid damage or injury.</p>

- Q: The construction of more than many floors must be used for construction elevators

- The average height is more than 12 stories. Construction elevators are often called construction elevators, but construction lifts include a broader definition, and construction platforms are part of the construction elevator series. Simple construction elevator is by car, driving mechanism, standard section, attached to the wall, chassis, fence, electrical system and so on several parts, manned cargo construction machinery is a frequently used in construction, because of its unique enclosure structure make it take up both comfort and safety, construction elevator is usually used with tower crane on the construction site, the average load in 1-3 tons, running speed is 1 to 60 m/min. The construction elevator of our country is more and more mature, and gradually goes to the international.

- Q: Construction site construction elevator and tower crane, which unit security check and acceptance?

- Different but most likely is the construction elevator

- Q: Is it possible to utilize a hydraulic cylinder in the construction of a building hoist?

- <p>Yes, hydraulic cylinders can be used in building hoists. They are often employed in lifting systems due to their ability to generate large forces in a controlled manner. Hydraulic cylinders provide smooth and precise control over heavy loads, which is crucial for the safe and efficient operation of a building hoist. They can handle the vertical movement of materials and personnel in construction settings, ensuring a stable and reliable lifting mechanism.</p>

- Q: Is it possible for a hydraulic cylinder in a building hoist to experience leakage or failure?

- <p>Yes, a hydraulic cylinder in a building hoist can leak or break. Leaks can occur due to worn seals, damaged hoses, or corroded cylinder walls. Breakage may result from excessive pressure, manufacturing defects, or metal fatigue. Regular maintenance and inspection are crucial to detect and prevent such issues, ensuring the safety and efficiency of the hoist system.</p>

- Q: What is the meaning of double straps in the construction elevator?

- One component of the elevator's drag system is the weight of the car. The other side of the car is connected to the top of the car by dragging a wire rope. It can be used for the energy saving of the elevator towing system, because the elevator load optimization is calculated by the theory calculation. The elevator should be calculated before the weight is weighed: the calculation principle is that the weight is equal to the weight of the car and half the load.

Send your message to us

Buidling Construction Hoist SC100 1000KG

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords