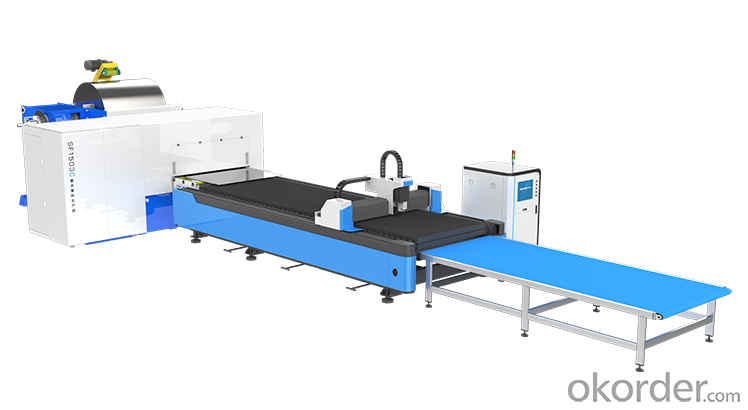

Automatic Metal Coil Decoiling Levelling and Blanking Fiber Laser Cutting Machine

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 unit

- Supply Capability:

- 10000 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction

Fiber laser blanking system combines a fiber laser cutting machine with an automatic metal coil feeding system resulting in an efficient coil fed laser cutting solution .

Laser blanking reduces power consumption compared to its alternatives, such as press lines and results more efficient and flexible.

The automatic design of the whole process, which is from loading-uncoiling-leveling-cutting saves labor, realizes the net cutting of coil materials, and improves the utilization of sheet materials.

Parameters

Model | Coil-fed Laser Blanking System |

Applicable materials | Cold rolled coil, galvanized coil, stainless steel coil, aluminum coil |

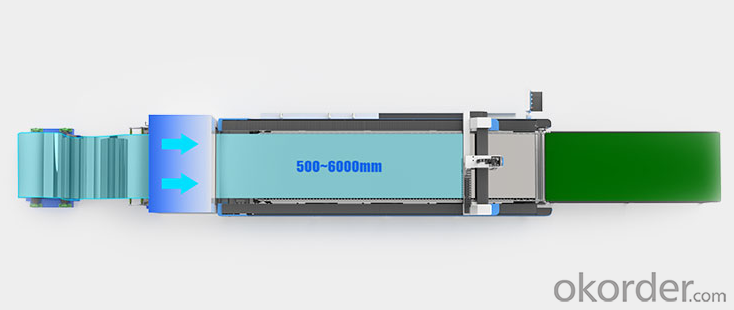

Working area(mm) | 3000*1500/4000*2000/6000*1500(mm) |

Laser power | 1kw/1.5kw/2kw/3kw/4kw |

Material thickness | 0.5-2mm |

Material width | 600-1500mm |

Maximum coil weight | 10T |

Maximum outer diameter of material | Φ1500mm |

Material inner diameter | Φ508/Φ610mm |

Feeding accuracy | ±0.5mm (calculated by 1000mm) |

CNC system | Feeding speed |

Details:

High work efficiency and cost saving

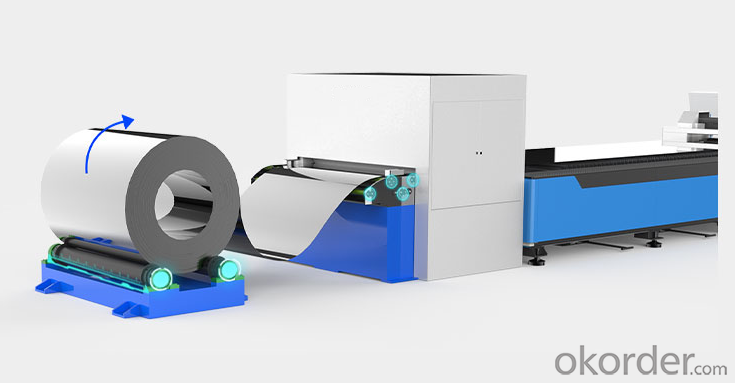

The load-bearing capacity of the single-support uncoiler is 10 T, and the feeding speed of uncoiler is 0-10m /min (stepless speed regulation).

Leveling sheet metal, eliminating the stress

After the coil is uncoiled, the plate is leveled by the leveling machine, and the stress of the plate during the leveling process is eliminated, so that the plate is smoother and a better cutting experience is obtained.

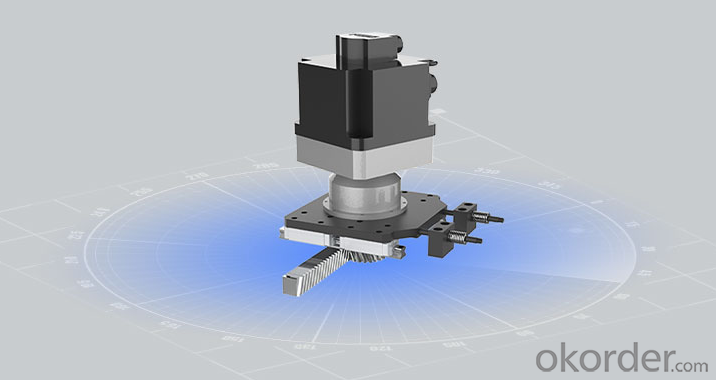

High precision positioning and rectifying process

The special screw nut is used to drive the rectifying roller to install the slide block, so as to realize the positive orientation of the plate , no need laser edging and save the cutting time of the plate.

High precision transmission structure

Ultra-precision transmission system is adopted, high transmission accuracy.

- Q: Which industries need laser equipment?

- Laser marking technology can be used in industry such as marking, welding, cutting, surface heat treatment and internal crystal carving.

- Q: Which femtosecond laser device is the most advanced?

- Many myopic friends who favour femtosecond laser surgery appear to be confronted with various femtosecond laser devices. The operation principle of femtosecond LASIK is to make corneal flap in the corneal stroma by femtosecond laser, and then use the excimer laser to change the corneal radian, so as to achieve the effect of correcting the visual acuity

- Q: Laser drilling equipment for laser drilling

- Laser is an important part of laser drilling equipment. Its main function is to convert the power provided by the power supply system into laser energy at a certain conversion efficiency

- Q: Where can I do private lasers?

- Private laser is to protect women's private and healthy laser equipment.

- Q: Laser processing equipment has several components

- The laser generator must have the cooling device, the focusing device.

- Q: What do you think of the laser equipment industry?

- Laser processing (including laser cutting, welding and surface treatment) is an advanced production technology.

- Q: What are the parts of the laser welding equipment?

- long time of welding normal operation. And cutting, input power and energy of the laser can be adjusted according to the processing requirements.

- Q: What kind of equipment is laser laser and what is it for? Please expert pointing

- Light transfer information for laser communications is very common today. For example, with communication signals of ship, red, yellow and green traffic lights scheduling.

- Q: Which is the leading domestic enterprise of laser equipment? What is the market share of the laser companies?

- Followed by unity, Chu Tian and so on. There are companies such as Punaze, Farley, Huagong laser's precision.

- Q: How much is the laser anti-counterfeit equipment?

- The most advanced anti-counterfeiting, but the specific depends on what material you are!

Send your message to us

Automatic Metal Coil Decoiling Levelling and Blanking Fiber Laser Cutting Machine

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 unit

- Supply Capability:

- 10000 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords