Automatic Disposable Plastic Cup Making Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 8 Sets per Month set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Detailed Product Description OF Automatic Disposable Plastic Cup Making Machine FJL-660SB-E

1.Automatic servomotor cup making machine

2.operated by PLC and touch screen

3.Good qulity ,work stable

4.Certification:CE

Usage OF Automatic Disposable Plastic Cup Making Machine FJL-660SB-E

This machine is used for making disposable products as plastic cups, plastic bowls, ice cream cups, cold drinking cups, yoghurt cups, instant-food boxes and bowls, dishes, trays,lids and etc

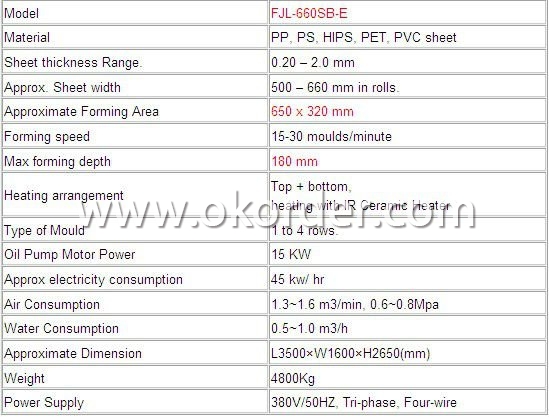

I.Main Technical Parameter OF Automatic Disposable Plastic Cup Making Machine FJL-660SB-E

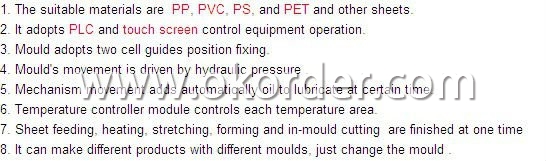

II.Main Construction Features OF Automatic Disposable Plastic Cup Making Machine FJL-660SB-E

- Q: I put on both sides of the glue, heating, adsorption, 10 minutes, or not, the temperature is 1With vacuum suction machine for leather, plastic suction always open, going on! I painted on both sides of the glue, heating, adsorption, 10 minutes, or not, the temperature is 100, an expert to point out! Thank you. If the problem is solved, there must be a thank you!

- Pad up and pad up to 2 centimeters,Chasing the answerWhere are you from?

- Q: Vacuum suction machine in the negative pressure irrigation what to do?

- Negative pressure tank is the vacuum tank used to store the amount of vacuum, because when the blister machine production needs instantaneous production of a large number of vacuum, a small vacuum pump is not able to meet the production of a large amount of instantaneous vacuum.

- Q: What is a blister worker?

- To understand this problem, from the beginning the blisterPlastic is a plastic processing technology, the main principle is the flat hard plastic sheet is heated to soften, using vacuum adsorption on the surface of the mold, cooling after molding, widely used in plastic packaging, lighting, advertising, decoration and other industries.Blister packaging: the use of plastic suction process to produce plastic products, and use the appropriate equipment for packaging products collectively.Blister packaging products include: bubble shell, tray, blister box, synonymous with: vacuum cover, bubble cap and so on.The main advantages of plastic packaging, saving raw materials, light weight, convenient transportation, good sealing performance, meet the environmental requirements of green packaging; packaging to any shaped products, packing without additional cushioning material; a packaged product is transparent, beautiful appearance, easy to sell, and is suitable for mechanical and automatic packaging, easy to the modernization of management, save manpower and improve efficiencyBlister packaging equipment mainly include: plastic forming machine, punching machine, sealing machine, high-frequency machine, folding machine.Packaging products can be divided into: insert card, suction card, double bubble shell, semi bubble shell, fold bubble shell, seventy percent off bubble shell, etc..The plastic suction worker is the person who accomplishes the work mentioned above

- Q: Blister machine on the mold fast, the next mold is slow, what is the reason?

- Touch the chassis, then look at the vacuum tube, where other places, it is necessary to seal the above, has been open to listen to the vacuum, to see where it is leaking. Find a place and think about it.

- Q: I would like to ask you who can provide the "procedures" plastic absorbing machine to me.

- Specific depends on what kind of blister machine, it will be a little different.

- Q: I'd like to know about its product. Please use it to evaluate it

- If you want to know what your look not to know, is seeing is believing

- Q: the product blister packaging PVC, after a period of time, plastic will be torn off.

- Machine temperature is stable, blister has not been sprayed release agent.

- Q: Plate furniture engraving machine, blister machine production process is good?

- Batch engraving machine is a great investment.

- Q: What kind of oil for blister machine and blow molding machine?

- Hydraulic components should be selected according to the working temperature 46 or other types of hydraulic oil;Vacuum pumps use special vacuum pump oil

- Q: Vacuum suction machine Blister PVC film temperature is generally?

- One of the main processes in the vacuum forming process of thermoplastic sheets and films is sheet heating. The furnace is made of stainless steel, high temperature heating tile Taiwan, Japan line, high-frequency ceramic joints, 60 pieces of heating on the stove tile, under 42 watt heating furnace, the maximum power 40.8KW, South Korea DPC digital proportional regulator, a control regulating temperature, and a temperature display temperature, convenient data management. Electric furnace cylinder drive, power failure or overhaul, electric furnace out of the machine, safe and convenient.

1. Manufacturer Overview

| Location | Zhejiang, China |

| Year Established | 2002 |

| Annual Output Value | US$2.5 Million - US$5 Million |

| Main Markets | South America Eastern Europe Southeast Asia Africa Oceania Mid East Eastern Asia Domestic Market |

| Company Certifications | CE;ISO9001/2000;CE |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Callo,Algiers |

| Export Percentage | 81% - 90% |

| No.of Employees in Trade Department | 3-5 People |

| Language Spoken: | English, Chinese |

| b) Factory Information | |

| Factory Size: | 1,000-3,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | High and/or Average |

Send your message to us

Automatic Disposable Plastic Cup Making Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 8 Sets per Month set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords