Anthracite Low-volatile Bitumious Coal and Anthracite

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

1.Structure of Anthracite Description

Anthracite is made from Shanxi,the coal capital of the word .The quality is very high due to its unique resource .It has been exported to most of the world ,especially to Japan and Korea,as well as mid east.

It is commonly used in drinking water ,food industry ,chemical /dyeing industry ,sea/salt water filtration ,petro-chemical industry ,pulp/paper industry ,sauna,spa,pool,boiler ,etc.

Advantages:

1. Longer Filter Runs2. Faster Filtration3. Long Lifetime4. Good Separation Characteristics5. Savings water and power in washing6.Removes more iron and manganese salts tration ,petrochemical industry ,pulp /paper industry ,sauna,spa,pool,boiler,etc.

2. Main Features of Anthracite

Fixed Carbon: 78 %

Ash: 18 %

Volatile Matter: 4 %

Sulphur: 1.0 %

Moisture: 11 %

Gross Calorific Value: 6450 Kcal

Size: 0 mm - 19 mm: 90%

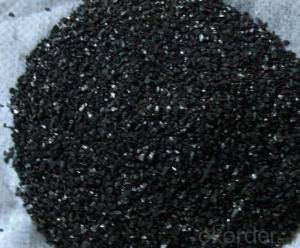

3. The Images of Anthracite

4. The Specification of Anthracite

1. Fixed carbon: 90%min

2.Uniform particles

3.Good separation characteristics

4. Long life

5. Widely used

6.activated anthracite:

7.Certificate: ISO9001, ISO9002, NSF

8.Usage: for water and air purification, etc.

5.FAQ of Anthracite

1). Q: Are you a factory or trading company?

A: We are a factory.

2). Q: Where is your factory located? How can I visit there?

A: Our factory is located in ShanXi, HeNan, China. You are warmly welcomed to visit us!

3). Q: How can I get some samples?

A: Please connect me for samples

4). Q: Can the price be cheaper?

A: Of course, you will be offered a good discount for big amount.

- Q: What is the role of activated carbon in the process of water purification

- Physical adsorption, clear after the coarse filtration / precipitation / softening after the last process: adsorption of fine insoluble and odor.

- Q: What is lean coal, lean coal classification

- (2) lean coal (PM). Coal is a high degree of coalification coal, non caking or slight adhesion. No coking coking furnace. In the laminar flame, burning resistance.(3) lean coal (PS). Lean coal is a kind of high rank and low volatile bituminous coal and weakly caking. Typical coal coking, coking, coke powder are generated.(4) (SM). Coal coal is low volatile medium caking coking coal. Can produce a certain amount of colloid in coking. Separate coking, can get large blocks, crack less, shatter resistant better coke, but poor wear resistance of coke.

- Q: The difference between raw coal and fuel coal

- It burned after no tobacco ~ how professional. I study chemistry.

- Q: On behalf of the company to study the coal test, which can help me to explain the online test of coal each indicator of the process, thank you

- (2) the external and internal moisture of coalThe free water of coal is divided into external and internal water.External moisture, which is attached to the surface of coal particles. The external water is easy to evaporate in the dry air at the normal temperature, and the vapor pressure which evaporates to the surface of the coal particles does not evaporate when the air pressure is balanced with the air.Internal moisture, which is adsorbed in the pores of the coal particles. The temperature of the internal water needs to be above 100C to evaporate after a certain time.

- Q: Soft, hard charcoal, what is the difference? Which is more suitable for painting head?Which brand is better?There are charcoal and carbon. What is the difference?

- Hardness is not the same as the refill, followed by increasing.A: the refill by charcoal, charcoal type according to hardness refills can be divided into three kinds of soft, hard, and size of the. The use of different hardness because of the picture effect, and painting began with a soft proofing charcoal, because of its easy and erase, repeated correction, not to hurt the paper, then a detailed modification when the hard charcoal, this process with corresponding changes in their painting level, to fit for. The use of charcoal and pencil, pencil hardness and refill is also according to the different types of. Where B is soft, the hardness increases from 6B to 1B; H is hard, increasing from 1H to 6H. In addition, the charcoal black in color, strong expression ability, is an ideal tool for painting sketch, portrait is a plus, but it is difficult to wipe off heavy painting.

- Q: Coal water slurry is used for what?

- Coal water slurry technology including the key technology of coal water slurry preparation, storage and transportation, combustion and additives, is a multi-disciplinary system technology of coal water slurry with high combustion efficiency and low pollutant discharge characteristics, can be used for power plant boilers, industrial boilers and industrial furnaces for oil and gas, coal combustion generation generation, is an important part of the clean coal technology.

- Q: Artificial gamma (density) curve: the coal seam has obvious abnormal reflection;Apparent resistivity curve: the coal seam is relatively low amplitude anomaly, and the sandy mudstone is high amplitude reflection;Natural gamma curve: the coal seam is relatively low amplitude, but the sandy mudstone is high amplitude.Graduation picture does not explain the above explanation is a bit simple, trouble to explain a little bit more,Sit back and wait

- As well as the "four low" characteristics: low natural gamma, low compensation density, low cross section, low acoustic impedance, and dark color;

- Q: Effect of carbon on steel

- The formation of solid solution organization, improve the strength of steel, such as ferrite, austenite structure, dissolved in carbon elements;2 carbide structure, can improve the hardness and wear resistance of steel. Such as cementite, that is, Fe3C, carbide structure.

- Q: Coal formation process and time

- Coal is millions of years of plant leaves and roots, stacked on the ground with a layer of very thick black humus, due to changes in the earth's crust constantly buried underground, long isolated from the air and under high temperature and pressure, after a series of complex physical and chemical changes and other factors, the formation of black combustible sedimentary rocks, which is the coal forming process.

- Q: I was a major in geological engineering, in the practice of mineral petrology, the teacher asked, "the mineral composition of coal?" Is a mineral petrology, coal chemistry is not in, please master, senior students. Thank you

- The composition of coal is mainly composed of organic matter, which is mainly composed of carbon, hydrogen, oxygen, nitrogen and other elements. There are ten kinds of elements in coal, but the elements of coal are usually composed of five elements, namely carbon, hydrogen, oxygen, nitrogen and sulfur. In coal, the content is very small, a large variety of other elements, generally not as the composition of the elements of coal, but only as an element or trace elements in coal.

Send your message to us

Anthracite Low-volatile Bitumious Coal and Anthracite

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches