Aluminum Household Foil Jumbo Roll with 8011 Alloy Tempo O

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 300 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Thickness | 0.1mm-8mm |

Popular Thickness | 0.1mm/0.2mm/0.25mm/0.3mm/0.6mm/0.8mm/1.0mm/1.2mm/1.5mm/2.0mm/3.0mm |

Width | 20mm-2500mm |

inner diameter | 76mm / 152mm |

Material | AA1050, AA1060, AA1070, AA1100, AA1235, AA3003, AA3004, AA3005, AA5052, AA5005, AA5754, AA5083, AA8011, AA8079, etc |

Temper | O,H12,H14,H16,H18,H22,H24,H26,H32,H34,H36,H38, |

Surface | Mill finish / Coated |

Packing | Export standard wooden pallets |

Payment Terms | 100% irrevocable L/C at sight or 30% T/T in advance as deposit,70% balance against the B/L copy |

Minimum Order Quantity | 5000kg |

Delivery time | 30-35 days after the receiving L/C or deposit |

2. Application of

(1) Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors, windows,

(2) Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations.

(3).Advertisement: display platforms, signboards, fascia, shop fronts.

3. Feature of

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS (if clients request, paid by client), MTC (plant provided), Certificate of Origin (FORM A, FORM E, CO), Bureau Veritas (if client request, paid by client), CIQS certificate and so on.

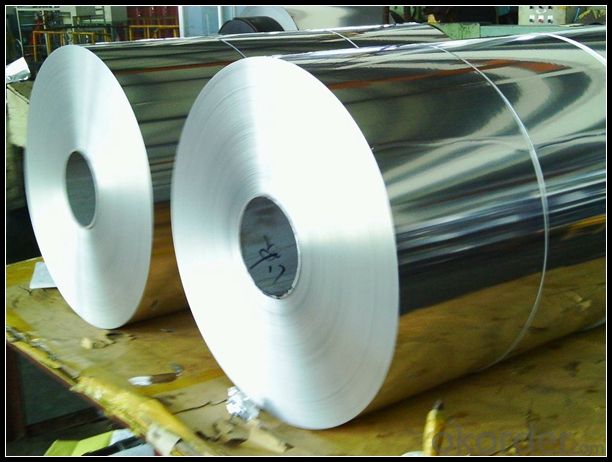

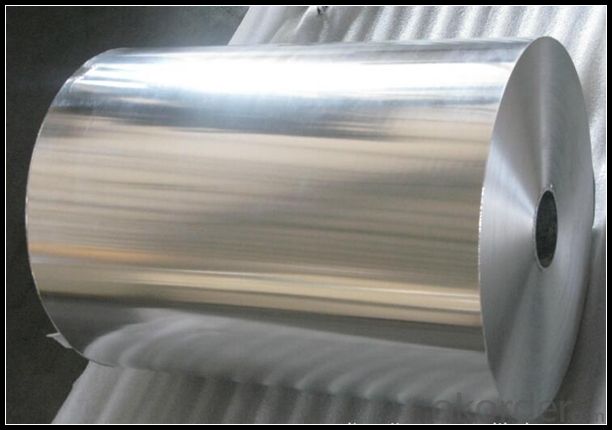

5. Image of

6. Package and shipping of

Eye to wall

Eye to the wall

With wooden pallet (wooden case also available)

7. FAQ

1) What is the delivery time?

Depends on actual order, around 30 to 35 days

2) What is the QC system?

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: Considerations for hand held aluminium foil sealing machine

- This machine uses the single phase three wire power line, in order to make the operator safety, must use the single-phase three wire system electric outlet, the work place ground must be dry, in order to maintain the insulation.

- Q: Does the FFC package foil have no grounding, which is equivalent to adding a capacitor to the cable?

- If the single ended ground is not connected, as you say, it is equivalent to adding a capacitor to the ground;

- Q: Plastic container for food packing container

- By single or composite materials by blow molding, vacuum, extrusion, injection molding method made of plastic bottles, cups, trays and plastic containers: to adapt to a variety of drinks, fast food and frozen food packaging. As for PET bottles, beverage bottles and PVC PP bottles, transparent appearance, light and strong features for fast food; polypropylene disc has the characteristics of heat resistance, sterilization temperature, which can contain jam, fruit and vegetable food heat sterilization; frozen food packaging is widely used in polyolefin plastic cup.

- Q: What is the material of aluminum foil

- A kind of aluminum rolled into sheets of hot stamping material, the effect of stamping and silver foil stamping similar effects, it is also called the false.

- Q: Are aluminum foil lunch boxes much used in the country?

- For the Chinese, it is a new food container, so it is still relatively new.

- Q: What is the recycling of aluminum foil packs?

- Not only recycling paper lunch boxes to be put into the container, but also to the aluminum foil bag thrown into the container, rather than paper, because not all components of the aluminum foil bag inside pulp, and plastic film 20% and 5% aluminum foil, if they are treated with waste paper, paper pulp dispersion time is not enough, no crime was isolated from Crucian Carp it can lead to the recycling of the resources, if sent to incinerators will detract from the life of the incinerator.

- Q: Is the quality of aluminium foil lunch box good? It looks good. Ha, it looks pretty tall. I don't know if it's reliable

- Really haven't seen, general take away boxes are transparent plastic, feel first is not green, second will be toxic

- Q: Does the disposable aluminum foil lunch box affect your health?

- Aluminum foil used as a food container has the characteristics of safety, health, high and low temperature resistance, green environmental protection, regeneration, energy saving, good sealing and so on.

- Q: Hand held aluminum foil induction sealing machine, how long is the sealing time?

- The hand-held aluminum foil sealing machine is a machine which uses electromagnetic induction principle to induction, heat and seal plastic, glass and other non-metal bottles and ring containers. For metal containers, do not use this machine seal.Recommend a small number of products, practical handheld aluminum foil sealing machine. It is the first choice for small businesses to save equipment costs. This machine can adjust sealing power according to sealing size. The bottle neck can be used between 20 and 100 millimeters in diameter

- Q: Where is the use of high pressure etching into electronic aluminium foil?

- China's electrolytic aluminum capacitor development is also very fast, according to statistics, in 1997 production of about 15 billion, it is estimated that in the near future may have more than 20 billion. Judging from the development of China's electronic industry, the output of aluminum electrolytic capacitors will be greatly improved in recent years. At present, some parts of China's electrolytic capacitor foil are made in China, and a considerable number of them rely on imports.

Send your message to us

Aluminum Household Foil Jumbo Roll with 8011 Alloy Tempo O

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 300 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords