Rock Wool Reinforced Aluminum Foil Laminated Cryogenic Insulation for LNG Cylinder

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Cryogenic insulation paper(P paper/Z paper)/aluminum foil(or aluminized polyester film) compositions are laminated of Cryogenic insulation paper and aluminum foil(or aluminized polyester film).These products can be wrapped to the cryogenic inner tank directly and no need to composite by user. Therefore ,it can effectively reduce the waste of material and hugely increases efficiency. The width varies from 40mm to 1800mm.

Specification

| technical specification | aluminum foil | aluminized polyester film |

| condition | anneal | vcauum aluminizing |

| Thickness | 0.0065 | 0.012 |

| surface oiliness | without oil, not less than calss B on brush water test | No oil |

| Harmful Element(%) | Pb<0.01 Cd<0.01 As<0.01< span=""> | / |

| Width | 30-1780 | 30-1780 |

Applications of Aluminum Foil Laminated Cryogenic Insulation Paper

Aluminum foil laminated cryogenic insulation material (paper) is widely applicable in the cryogenic industry on such equipment and devices as Dewar, vehicle cylinder, LNG tanker, LNG storage tank, LNG vessel, cryogenic piping system, skid-mounted gas filling station and etc.

Advantages of Aluminum Foil Laminated Cryogenic Insulation Paper

Flame-retardant

Light

High tensile strength

Low heat conductivity coefficient

Large thermal contact resistance

Low air content under the vacuum and broad operating temperature(-269℃-500℃)

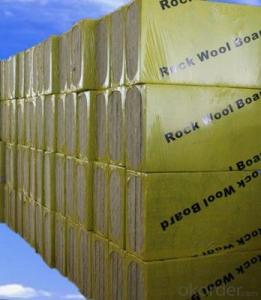

Image of Aluminum Foil Laminated Cryogenic Insulation Paper

FAQ

Q1: How do you control the products quality?

A1: With strict uality control system throughout the materials selection and production process, our refractory and ceramic fiber products quality is effectively controlled to meet customer requirements.

From the raw materials selecting, our quality control begin. The quality certificates of raw materials are required and each batch will be tested before using. During production, the quality control are conducted by workers and then each piece will be sorted and examined by quality supervis

Q2: What`s the lead time for my order?

A2: It depends on customers’ requirements and our production schedule. And usually we need 30-60 days for refractory bricks,10-25 days for unshaped refractory materials and 10-20 days for ceramic fiber blankets.

- Q: What does the rock wool board look like?

- The initial development of Hebei Langfang Dacheng in the building is a common type of application for industrial buildings should be consistent with "building insulation materials, the type of application and basic requirements"

- Q: What role does dolomite play in rock wool products?

- What role does dolomite play in rock wool products?

- Q: Rock wool products are divided into several categories

- Which rock wool board in the application of more interior decoration. Rock wool board specifications are usually as follows: long (mm) 900,100; width (mm) 500,600,700,800; thick (mm) 30,40,50,60,70

- Q: How to judge the quality of rock wool

- Rock wool products, the important content of rock wool products, the density range is kg / m3 100-250 ± 15%, in this density of rock wool board to meet product quality requirements

- Q: The difference between rock wool and rock wool

- The difference between rock wool and rock wool

- Q: Rock wool products and aluminum silicate acupuncture blankets are same

- Rock wool products and aluminum silicate acupuncture blankets are same

- Q: Rock wool insulation material fire rating is how much

- Rock wool insulation material fire rating is how much

- Q: Rock wool board is inorganic composite insulation material

- Rock wool board is inorganic composite insulation material

Send your message to us

Rock Wool Reinforced Aluminum Foil Laminated Cryogenic Insulation for LNG Cylinder

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords