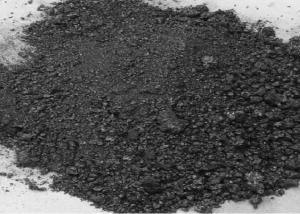

Aluminium Aarbon Anode Block

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 60 Metric Tons m.t.

- Supply Capability:

- 10000 Metric Tons per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Features of Aluminium Aarbon Anode Block

1 large manufacturer of carbon block

2 good quality and competitive price

3 used in aluminium smeltering

Specifications of Aluminium Aarbon Anode Block

Properties |

Range |

unit |

C.T.E. |

≤5.0 |

10-6/K |

Real Density |

≥2.04 |

g/cm 3 |

Electrical Resistivity |

≤55 |

μΩ.m |

Compressive Strength |

≥32 |

Mpa |

CO2 Reactivity |

≤80 |

% |

Bulk Density |

≥1.53 |

g/cm 3 |

Ash |

≤0.50 |

% |

S |

≤1.50 |

% |

Si |

≤0.05 |

% |

Fe |

≤0.05 |

% |

V |

≤0.015 |

% |

- Q: Ask the proportion of non-burning brick ingredients, raw materials: cement fly ash powder; if the addition of "rock sand fine" can reduce the amount of cement?

- Rock and crystal cement cement can also be appropriate to reduce the percentage of 1-2 cement, but not too much, no burning brick raw material mixing unlike other cement components, the more stirring itself can not be washed to play the role of rock crystal, If the production of some of the rough surface of the brick may also be appropriate plus also in the sand, hoping to help you, if there is nothing to understand the place can also add their own, professional maintenance Mianshaozhuanji, to restore production efficiency, personnel training, Can be served all over the country Deduct the word to the points

- Q: What is the block of the external wall of the frame structure?

- Aerated concrete block, I am simply silent to you, I answered your question, you put someone else casually answer the adoption of the

- Q: University Building Materials: What is the difference between aerated concrete blocks and steamed fly ash blocks?

- Filling and steaming are all a process in the production process Gas is aluminum or aluminum foil and calcium hydroxide reaction to generate a large number of bubbles; steaming is semi-finished products in the autoclave through the high temperature and humidity to complete the curing process aerated concrete blocks according to the different raw materials are generally divided into sand aerated concrete blocks and fly ash aerated concrete blocks (sand and fly ash are one of the siliceous materials, as well as tailings, stone powder some type of)

- Q: , How to convert, the cement label can be reduced from 325 to what level . how much depth of the foundation to reduce the number of bars to reduce the number of excavation area to reduce the number of 3

- Light weight aerated concrete dry bulk density is generally 400-700kg / m

- Q: What is the height of the building material stacking at the construction site? Like red brick, steel, template or something

- Saving land, but also to facilitate the extraction of steel

- Q: What are the block materials used in our masonry works? In recent years, what are the changes in wall materials?

- Masonry structure Masonry structure is made of block material, block type: sintered bricks, non-sintered bricks, concrete small hollow block, stone four categories

- Q: Do the material of the masonry be used in the structural description or in the building description?

- When the budget is made, the material of the masonry is in the structural description

- Q: What is the difference between packing density and bulk density in building materials?

- Filling density: for solid blocks; such as concrete, brick, block

- Q: Construction projects contracted outside the network need to purchase the building materials which? Such as covers, sewage pipes ... experts to answer, the more specific the better material, thank you

- Steel pipe, brick, cement, sand, cover, tee, elbow, adjustable, compensator, and so on. , The production of fixed section of the iron plate.

- Q: Sand aerated concrete block and aerated concrete block difference, the price use? Inside and outside walls nature?

- Sand aerated concrete block is made of sand for the Si material, usually said that the aerated concrete block is the fly ash mixed with the weight of Fu Lu Huang Hao ketone ketone bundles of wood, Si material, sand plus high compressive strength, the price is high, are used in high-rise frame structure filled with materials, as a wall application

1. Manufacturer Overview

| Location | Shandong,China |

| Year Established | 1995 |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | ISO 9001: 2000 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b) Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminium Aarbon Anode Block

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 60 Metric Tons m.t.

- Supply Capability:

- 10000 Metric Tons per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords