1 1/4 Inch Plastic Pipe Fittings - 2024 PPR Equal Tee for Agriculture Fields at Good Price

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Introduction:

1) Cold / hot water supply facilities for public buildings

2) Food, chemical, electronic industry pipeline networks; Such as Pipeline networks for transporting all kinds of corrosive liquids

3) Drinking water production system pipeline networks; Such as Pure water and mineral water

4) Air conditioning facility pipelines

5) Compressed gas pipeline networks for industry

6) Pipeline networks for swimming pools

7) Pipeline networks for solar energy facilities

8) Agriculture and garden production transporting systems

Packaging Details:

1. Large carton: 515 x 400x 220 Cubage: 0.04532 M3

Small carton: 390x255x250 Cubage: 0.0248 M3

2. PE poly bag+ carton Delivery Detail: 15 days/ 20" container; 25 days/ 40HQ

Product Description:

Product name | Size | Weight | Pack |

Equal tee | (Gram/m) | (m/pack) | |

T16 | 12.5 | 1300 | |

T20 | 19.4 | 800 | |

T25 | 30.5 | 450 | |

T32 | 48.2 | 260 | |

T40 | 90.8 | 150 | |

T63 | 275.3 | 54 | |

T75 | 515.0 | 30 | |

T125 | 1544.0 | 8 | |

T160 | 2531.0 | 4 |

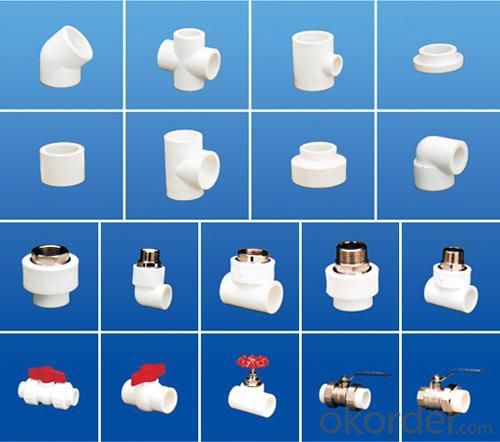

Product Show:

Company Information:

CNBM International Corporation (CNBM International) is the most important trading platform of CNBM Group Corporation, a state-owned company under the direct supervision of State-owned Assets Supervision and Administration Commission of the State Council.

CNBM International is highly recognized by its business partners and clients all over the world and has obtained rapid development under the spirit of win-win. We will carry on the mutual beneficial, innovative and revolutionary trading structure as we did before, create value for our employees, share holders and clients and benefit the whole society in our future development.

Advantages:

1, High Temperature Resistance: the maximum sustained working temperature is up to 70 Degrees Celsius, the maximum transient temperature is up to 95 Degrees Celsius.

2, Heat Preservation: low thermal conductivity which is only 1/1500 of brass pipe, and 1/250 of steel pipe.

Non-toxic: no heavy metal additives would not be covered with dirty or contaminated by bacterium.

3, Corrosion Resistant: resist chemical matters or electron chemical corrosion.

4, Lower Installation Costs: light weight and ease of installation can reduce installation costs by as much as 50% over metal piping system.

5, Higher Flow Capacity: smooth interior walls result in lower pressure loss and higher volume than metal pipes.

6, Long Life: more than 50 years under normal conditions.

7, Recycled and Environment-friendly

FAQ

Q1: How Can I Get A Sample?

A1: You can get samples by communicate with our export sales.

Q2: How Long Is Delivery?

A2: Delivery time will be30-45days according to order quantity.

Q3: What Is The MOQ?

A3: MOQ depends on different items.

Q4: What Is Our Normal Payments Terms?

A4: Our normal payment terms now is: T/T, L/C or western union, pay

- Q: Are plastic pipe fittings resistant to seawater and saltwater?

- Yes, plastic pipe fittings are generally resistant to both seawater and saltwater.

- Q: Can plastic pipe fittings be used for irrigation sprinkler systems?

- Yes, plastic pipe fittings can be used for irrigation sprinkler systems. They are commonly used due to their durability, affordability, and resistance to corrosion. However, it's important to select fittings that are specifically designed for irrigation purposes to ensure proper functionality and compatibility with the system.

- Q: Are plastic pipe fittings resistant to extreme temperatures?

- Yes, plastic pipe fittings, depending on the type of plastic used, can be resistant to extreme temperatures.

- Q: What are the disadvantages of using plastic pipe fittings?

- One of the main disadvantages of using plastic pipe fittings is their susceptibility to degradation over time. Plastic can weaken and become brittle when exposed to extreme temperatures, sunlight, or certain chemicals, leading to cracks, leaks, or even complete failure of the fitting. Additionally, plastic pipe fittings may not be as durable as metal alternatives, making them more prone to damage during installation or maintenance. Finally, plastic fittings may have lower pressure and temperature ratings compared to metal fittings, limiting their suitability for certain applications.

- Q: Are plastic pipe fittings resistant to acid solutions?

- Yes, plastic pipe fittings are generally resistant to acid solutions.

- Q: Are plastic pipe fittings resistant to impact damage?

- Yes, plastic pipe fittings are generally resistant to impact damage. They are designed to withstand common impacts and pressures encountered in plumbing systems. However, the level of resistance may vary depending on the type and quality of the plastic used in the fittings.

- Q: Can plastic pipe fittings be used for marine applications?

- Yes, plastic pipe fittings can be used for marine applications. There are several types of plastic materials, such as PVC (polyvinyl chloride) and CPVC (chlorinated polyvinyl chloride), that are specifically designed to withstand the harsh conditions of marine environments, including exposure to saltwater and UV radiation. These plastic pipe fittings are corrosion-resistant, lightweight, and easy to install, making them suitable for a wide range of marine applications such as plumbing, ventilation, and waste management systems on boats, yachts, and other marine vessels.

- Q: Do plastic pipe fittings require any special supports or hangers?

- Yes, plastic pipe fittings typically require special supports or hangers to ensure proper installation, stability, and to prevent sagging or stress on the pipes. These supports or hangers are designed to securely hold the pipes in place, maintain alignment, and distribute the weight evenly.

- Q: Can plastic pipe fittings be used for dairy processing plants?

- Yes, plastic pipe fittings can be used for dairy processing plants. Plastic pipe fittings are commonly used in the food and beverage industry due to their resistance to corrosion, durability, and ease of installation. However, it is important to ensure that the plastic materials used are food-grade and comply with the necessary regulations and standards for dairy processing.

- Q: How do plastic pipe fittings compare to metal fittings?

- Plastic pipe fittings are generally less expensive, more lightweight, and easier to install compared to metal fittings. However, metal fittings are typically more durable, have higher heat resistance, and offer better pressure handling capabilities. The choice between plastic and metal fittings depends on the specific application, budget, and desired performance.

Send your message to us

1 1/4 Inch Plastic Pipe Fittings - 2024 PPR Equal Tee for Agriculture Fields at Good Price

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches