2016 fully automatic electric carton box pp belt bundle strapping machine

- Loading Port:

- Xiamen

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 700 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

2016 fully automatic electric carton box pp belt bundle strapping machine

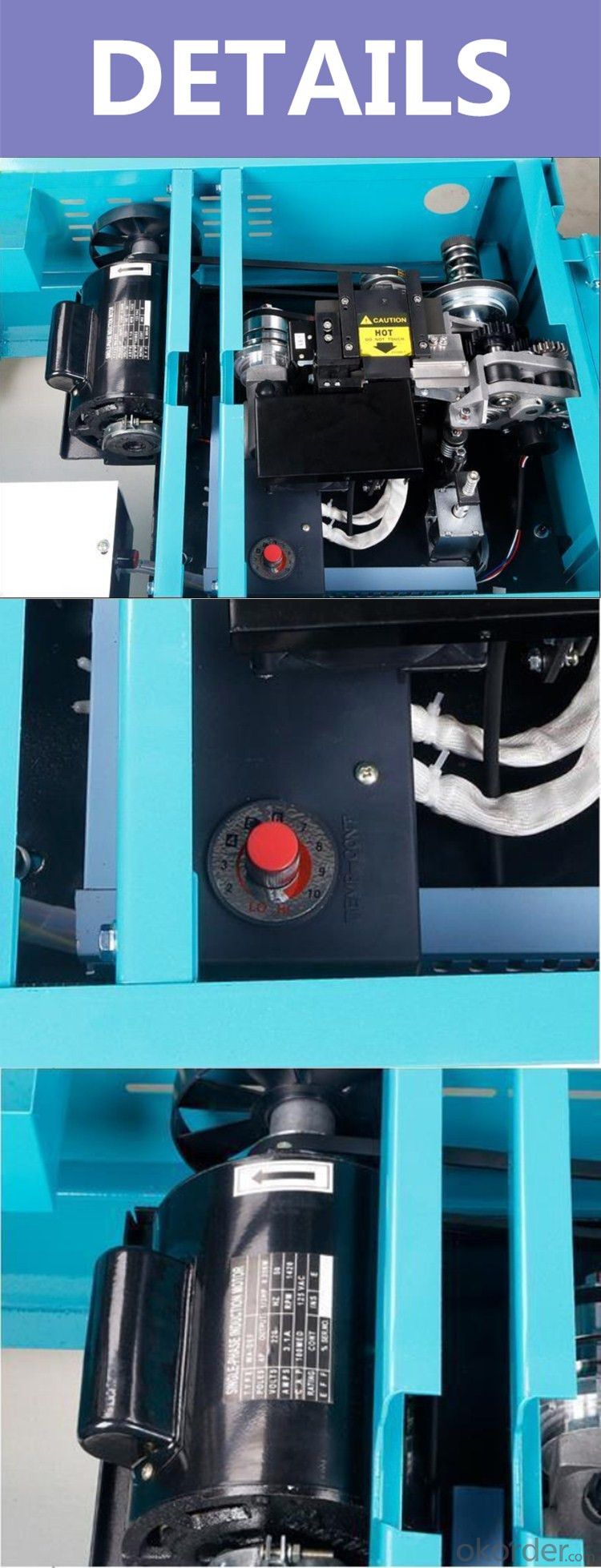

DETAILS

The Specification of Strapping machine LF101A | |

ITEM | LF101A |

Color | Grey |

Machine dimension | L1400*W640*H1475mm |

Strap width | 50mm |

Machine weight | 200kg |

Voltage/power | 380V/50HZ |

Strap width | 50mm |

Shrinking force | 25 - 700 KG |

Automatic Grade | Automatic |

Max Strapping size | 800mm*600mm |

Strapping speed | ≤2.5Second/Strap |

Strap types | PP or PE |

MORE PRODUCT

Our Factory

AFTER SERVICE

we can provied engineers available to service machinery overseas

Free replacement easily damaged parts for 1 year

CONTACT US

JUST CONTACT ME TO GET THE QUOTATION.

- Q: Ask a mechanical problem, the waste film recycling in the packaging machinery is a new film packaging, after cutting, then use the roller to recycle the waste film. Encounter a

- Is it settled?. Not really! It is not recommended to use torque as parameter control here. This is a tricky amount of control. And easy to fluctuate, prone to misoperation

- Q: What is the price of a small jujube packing machine?

- Small packaging machine is mainly divided into single grain and multi grain packaging, there are 3-6, there are about 200000. Mainly depends on the performance and use of the machine

- Q: What kind of reducer is commonly used in packaging machinery?

- Generally speaking, gear reducer, planetary gear reducer, and the most common one, these equipment power is relatively small, and some need to take the brakes of the motor reducer

- Q: What's the best place to use the pillow type packing machine?

- Suggest that manufacturers can find communication, there is no technical strength,

- Q: What is the name of the paper used in packing machine parts and yellow?

- Rust preventive action, commonly used for steel vapor rust preventive paper, but also for a variety of metals.

- Q: How much is the tableware wrapping machine?What's the price of the tableware wrapping machine?

- Tableware packaging machine packaging production, simple operation and high degree of automation, high efficiency, low packing cost, save labor, reduce the damage and the characteristics of two pollution, by tableware shrink packaging is widely used in all kinds of, is a very mature model

- Q: Which friend is an expert in mechanical equipment or a better understanding of sealing machines? Tell me how to identify the equipment

- If these are good, and then talk about the price, always a penny goods, this side, quick packaging machine is not bad,

- Q: What are the structures of the packaging machinery?

- Is a company engaged in outsourcing clients, packaging, processing, packaging equipment, leasing, services, sales in one of the specialized companiesSales of second-hand packing equipment according to the customer's product features and requirements. Reduce customer purchasing costsAccording to the customer's product characteristics and requirements. Select the best packaging equipment for customers, reduce customer purchasing costsPackaging equipment spare parts sales and maintenance services

- Q: What's the fastest packing machine?

- 3 ideal speed of the package can reach 70 packs, that is, 70*3 = 210., and now there are 4 packages abroad. But the bags are small.

- Q: Will the Internet be too passive? Telephone marketing, what kind of food can be found in the factory, such as the phone, people basically do not need, and all have. Does the salesman run the market? How do you run? Thanks for the direction...

- Ha ha, as you say, TV factories are closed down, every household has a TV, but every day there will be a lot of people buy tv.

Send your message to us

2016 fully automatic electric carton box pp belt bundle strapping machine

- Loading Port:

- Xiamen

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 700 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords