Light Accessories For Cars

Light Accessories For Cars Related Searches

Decorative Ceiling Plate For Light Fixture Ceiling Plate For Hanging Light Fiber Sheet For Roof Light Accessories For Cars Transformer For Light Fixture 42 White Ceiling Fan With Light Waterproofing Additive For Cement Render Bedside Table With Light Light Fixture With Chain Light Steel VillaHot Searches

Steel Mesh Panels For Sale Price For Stainless Steel Scrap Scrap Price For Stainless Steel Price For Stainless Steel Stainless Steel Plate For Sale Stainless Steel Tank For Sale Stainless Steel Sheets For Sale Cheap High Tea Sets For Sale Stainless Steel Tanks For Sale Stainless Steel For Sale High Density Fiberboard For Sale Solar Hot Water Collectors For Sale Scaffolding For Sale In Uae Scaffolding For Sale In Ireland Scaffolding For Sale In Houston Type Of Inverter For Solar Price Of Shipping Containers For Sale Types Of Inverter For Solar Stock Price For Aluminum Steel Mesh Panels For SaleLight Accessories For Cars Supplier & Manufacturer from China

Okorder.com is a professional Light Accessories For Cars supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Light Accessories For Cars firm in China.Hot Products

FAQ

- Now decoration light steel keel 600X600 mineral wool board (ordinary) ceiling how much money a square meter?

- Package workers a square meter twenty yuan or so, Bao Gong Bao material will be about a square meter 70 yuan,

- I see the world are now light steel keel, that before the aluminum alloy keel is now out of date? What is the difference between aluminum alloy keel and light steel keel? Are there any market for aluminum alloy keel?

- Fast no market price is too high

- Office building silicon calcium board ceiling, the actual construction practices: light steel keel spacing 1000mm, small keel spacing 600mm meet the requirements

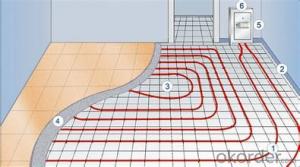

- 5, the installation of sub-keel 1> has been played by a good sub-keel sub-line, card sub-keel hanging pendant. 2> hanging sub-keel: according to the provisions of the provisions of the keel spacing, the sub-keel hanging hanging on the main keel, the design requirements, the general spacing of 500mm-600mm. 3> When the length of the keel to be a number of continuation of a long time, with the keel connection, hanging in the keel at the same time the connection, straighten the fixed. ?Install the cover panel, the installation of the panel before the end of the terminal equipment must be located on the ground and the various pipeline inspection and acceptance, before allowing the installation of the panel. Cover plate and light steel keel fixed method is: Light steel keel skeleton after acceptance, began to install the first layer of cement fiberboard. First in accordance with the room space on the cement fiber board layout, layout is not allowed to appear below 100mm slats. After the completion of the version, according to the layout placed cement fiber board, and with self-tapping wire fixed firmly. Self-tapping screw spacing of 150-170mm. After the completion of the first layer of cement fiberboard, should check the flatness of the allowable error should be controlled within 3mm. The first layer of cement fiberboard after the acceptance of the installation has been compressed composite panels, the installation of the use of adhesive method, the installation of the first two sides and then the middle.

- Whether the ceiling light steel keel has the raw material inspection standard

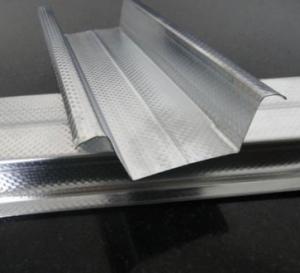

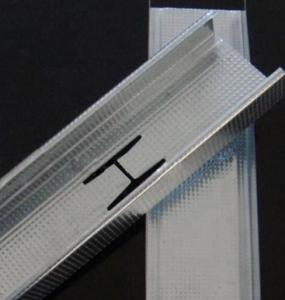

- The latest standard GB / T11981-2008 60 and 50 main bone thickness of 1.2mm, 38 main bone is 1.0mm, 50 bone 0.5mm, 60 bone 0.6mm

- Please give valid certificate, thank you! The

- The keel of the ceiling needs to be re-examined: Detection parameters Keel: size deviation, mechanical properties; Accessories: size deviation, mechanical properties. Keel ceiling project quality acceptance project: Ceiling elevation, size, from the arch and shape should meet the design requirements. Test method: observation; scale inspection. The material, variety, specifications, regiment and color of the facing material should meet the design requirements. When the facing material is a glass plate, use safety glass or take reliable safety measures. Inspection method: observation; check product certificate of competency, performance testing report and admission inspection records. Finishes should be tightly installed. The overlapping width of the facing material and the keel should be greater than two-thirds of the width of the keel. Test method: observation; hand pull check; scale check. Boom, keel material, specifications, installation spacing and connection should meet the design requirements. Metal boom, keel should be surface corrosion treatment; wood keel should be anti-corrosion, fire treatment. Inspection methods: observation; foot check; check product certificate of competency, admission acceptance records and hidden engineering acceptance records.

- Light steel keel ceiling calculation method

- Let the decoration of the people estimate, and then you go to buy.

- Light steel keel gypsum board ceiling need floor?

- Modeling more complex when the bottom of a good job, Moreover, plus the bottom plate can be more money ah. As far as possible Huayu customer plus such a greater profit it

- PVC plastic buckle plate ceiling with what keel ah?

- Local cracking Gong Guan folder pull the locust control Weihai even reason is the gypsum board between the seam is not handled well, no slot, no seam, seal gypsum is not dense, not paste the zipper and so will lead to cracking, when the hanging bar Not vertical, or hanging length of more than 1.5 meters and no anti-support, it will lead to local cracking. The quality of the main bone bones with the specifications of the construction are the factors that affect the cracking of gypsum board or not. Plaster layer off for many reasons, there are common plaster layer of the thickness of each layer is too thick, the grass is not dealt with the beginning of the batch of ash, the space is too large, the former plaster layer is not dry on the next wipe Gray, are the cause of the plaster layer off.