Door Handles Nz

Door Handles Nz Related Searches

1 Inch Particle Board Door Automation System 4 X 8 Particle Board Electric Door Closers Behind The Door Hooks Formaldehyde Particle Board Maple Particle Board Refinishing Particle Board Cabinets Particle Board Malaysia Particle Board NzHot Searches

Hotel Furniture Sales & Liquidators Hotel Furniture Suppliers Wholesalers Hotel Resale Furniture Heated Wood Floors Cost Wood Trim Suppliers Core Aerator For Sale Particle Board Price List 4X8 Particle Board Price Particle Board Manufacturers Usa Particle Board Manufacturers Association Particle Board SpecificationsDoor Handles Nz Supplier & Manufacturer from China

Okorder.com is a professional Door Handles Nz supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Door Handles Nz firm in China.Hot Products

FAQ

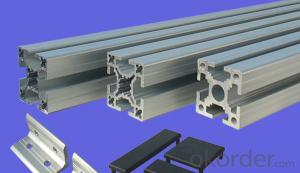

- There are several sealing options available for aluminum profiles, including anodizing, powder coating, liquid paint coating, and mechanical sealing. Anodizing is a popular choice, providing a durable and corrosion-resistant finish by creating a protective oxide layer on the surface of the aluminum. Powder coating involves applying a dry powder to the profile, which is then cured under heat to form a hard, smooth coating. Liquid paint coating can also be used, offering various colors and finishes, but may require more maintenance. Mechanical sealing involves using gaskets, tapes, or other sealing materials to create a tight seal between aluminum profiles. The choice of sealing option depends on the specific requirements of the application, such as desired aesthetics, durability, and environmental factors.

- Yes, aluminum profiles can be used for curtain wall systems. In fact, aluminum is one of the most commonly used materials for curtain wall construction due to its numerous advantages. Aluminum profiles offer excellent strength and durability, making them capable of supporting the weight of large glass panels. Additionally, aluminum is highly resistant to corrosion, which is essential for exterior applications where the curtain wall is exposed to various weather conditions. Moreover, aluminum profiles can be easily extruded into various shapes and sizes, allowing for design flexibility and customization. The lightweight nature of aluminum also makes it easier to handle and install, reducing labor and transportation costs. Furthermore, aluminum is a sustainable material as it is recyclable, contributing to the overall sustainability of the curtain wall system. Overall, aluminum profiles are a suitable choice for curtain wall systems due to their strength, durability, corrosion resistance, design flexibility, and sustainability.

- What is the difference between the two, or how to distinguish it from the outdoor curtain wall?

- Aluminum material refers to the blank material, which is used directly without artificial aging

- Yes, aluminum profiles are suitable for electrical grounding applications. Aluminum is a highly conductive material that allows for efficient flow of electrical current, making it an ideal choice for grounding systems. Additionally, aluminum profiles offer excellent corrosion resistance, durability, and cost-effectiveness, making them a reliable option for electrical grounding applications.

- Yes, aluminum profiles can be anodized for improved corrosion resistance. Anodizing is an electrochemical process that forms a protective layer of aluminum oxide on the surface of the metal. This layer not only enhances the appearance of the aluminum profile but also provides excellent corrosion resistance properties. During the anodizing process, the aluminum profile is immersed in an electrolytic solution and a direct current is applied. This causes oxidation to occur at the surface of the metal, resulting in the formation of a thick layer of aluminum oxide. This oxide layer is hard, durable, and tightly adheres to the underlying aluminum, providing a barrier against corrosion. The anodic oxide layer can further be enhanced by sealing it with various sealing methods, such as hot water sealing or chemical sealing. This helps to increase the resistance of the anodized aluminum profile against environmental factors like moisture, chemicals, and UV radiation. Anodized aluminum profiles have several advantages over non-anodized ones. They have improved resistance to corrosion, scratches, and wear. Additionally, anodizing can also provide the aluminum profile with a decorative finish, as it allows for a wide range of colors to be applied. Overall, anodizing is a highly effective method to enhance the corrosion resistance of aluminum profiles, making them suitable for various applications where protection against corrosion is essential, such as in construction, automotive, aerospace, and electronics industries.

- Yes, aluminum profiles can be commonly used for exhibition booths. Aluminum profiles are lightweight, durable, and easy to assemble, making them an ideal choice for constructing exhibition booths. Additionally, aluminum profiles offer flexibility in design and can be customized to suit specific requirements, making them a popular choice in the exhibition industry.

- Due to their unique properties and characteristics, aluminum profiles prove to be highly effective in applications involving vibration isolation. The utilization of aluminum profiles in such scenarios aids in the reduction and mitigation of vibrations, thereby establishing a stable and isolated setting. The high strength-to-weight ratio of aluminum profiles stands as one of the primary factors contributing to their efficacy in vibration isolation. Aluminum, being a lightweight material, enables the construction of structures capable of efficiently absorbing and dissipating vibrations. This lightweight nature ensures that the profiles do not add excessive weight to the system, as doing so could amplify vibrations instead of dampening them. Furthermore, aluminum profiles exhibit exceptional damping capabilities. Damping refers to a material's ability to absorb and dissipate energy from vibrations. Aluminum inherently possesses damping properties, which play a significant role in diminishing vibration levels. As a result, the profiles effectively isolate vibrations and prevent their transmission to other components or structures. In addition, aluminum profiles can be easily customized and designed to meet specific requirements regarding vibration isolation. Engineers can tailor the profiles' geometries and configurations to effectively attenuate vibrations. This design flexibility permits the optimization of profiles for diverse applications and environments, ensuring maximum effectiveness in vibration isolation. Moreover, aluminum profiles offer commendable corrosion resistance, a crucial factor in vibration isolation applications exposed to harsh operating conditions. This resistance to corrosion guarantees the durability and reliability of the profiles, maintaining their performance over extended periods. In conclusion, due to their lightweight nature, excellent damping capabilities, customization options, and corrosion resistance, aluminum profiles prove to be highly suitable for vibration isolation applications. Through their efficient absorption and dissipation of vibrations, aluminum profiles enable the creation of stable and isolated environments, effectively minimizing the impact of vibrations on surrounding components or structures.

- Yes, aluminum profiles are suitable for use in food processing environments. Aluminum is a widely used material in the food industry due to its excellent properties. It is lightweight, durable, and corrosion-resistant, making it ideal for applications in food processing where hygiene and cleanliness are crucial. Aluminum profiles can be easily cleaned and sanitized, which is essential in preventing contamination and ensuring food safety. They have a smooth and non-porous surface, which inhibits the growth of bacteria and makes them easy to maintain. Furthermore, aluminum has excellent thermal conductivity, allowing for efficient heat transfer and temperature control during food processing. This property is particularly important in applications such as food packaging, cooking, and chilling. In addition to its physical properties, aluminum is also non-toxic and does not react with food or beverages. It is an inert material, meaning it does not release any harmful substances that could contaminate the food being processed. Overall, aluminum profiles are a reliable and suitable choice for use in food processing environments. They meet the stringent requirements of the industry in terms of hygiene, durability, and safety, making them a popular choice for various applications in the food processing and packaging sectors.