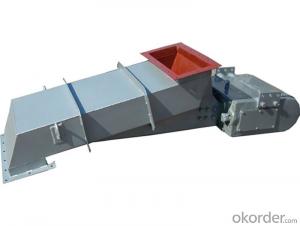

ZG vibrating feeder|High - quality feeder

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 15 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Vibrating feeder is the first equipment in the process of aggregate production line. The high-quality feeder helps the overall production efficiency of the aggregate production line.

The vibration feeder comprises a tank body, a vibration plate, a motor base and a vibration motor. In the traditional equipment, the bottom plate and the side plate of the tank are mostly using welding technology. This method is easy to produce welding deformation due to the welding stress. The improved feeder adopts bolt connection structure to solve the problem effectively. The motor base is the motor bearing The force of the place, especially through the steel plate cutting welding, after milling, and then drill hole drilling to ensure that the welding quality and size of precision; damping spring hydraulic universal testing machine to determine the value of static stiffness, the similar election With the number and then the whole assembly; vibration motor ring groove seal is used to ensure that the bearing lubrication effect, the vibration motor to play all the performance while a long service life.

These are only part of the equipment manufacturing, good equipment, only through advanced technology, good production equipment, and then by the superb work of the producers to produce its unique advantages.

- Q:The opening process of press filter from feeding to discharging is described briefly

- Open the central blowback return valve, send compressed air, and clean the inlet channel. The time is set according to the experience and the setting time.

- Q:How to choose crushing equipment suitable for its own ore material?

- Attention should be paid to the size of the feed port of the crushing equipment and the size of the feed size, whether it matches the material, such as whether the material can enter the machine and produce it smoothly

- Q:What's the simplest ore radio to do?

- The antenna metal wire, metal ores and stylus, wooden box, 8 ohm headset, etc.. (ore radios don't need electricity.)

- Q:Which God knows, hammer crusher, according to the material into which there are several categories?

- Axial feed from the main shaft into the crushing chamber, suitable for crushing grain, but after feeding the entrance to install slices, but also crushing grass, stems and so on.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

ZG vibrating feeder|High - quality feeder

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 15 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords