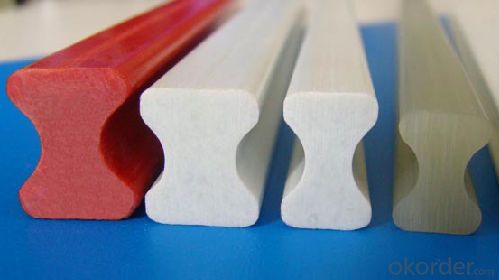

Transformer And Electric Reactor Used insulation Dogbone

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 kg

- Supply Capability:

- 200000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Brief Introduction

Trasformer insulation parts series of our company mainly including insulation sheet,i-shape,corner piece and so on.It could be classfied as class F,H and C according to temperature resistant.We can produuce epoxy series,cinyl series and polyester series according to client's requirements.

2.Characteristics

Based on productive technology and long time experience.the advantages of our product as following

1)High mechanical strength.

2)High grade of temperature resistant.

3)Smooth and elegant surface

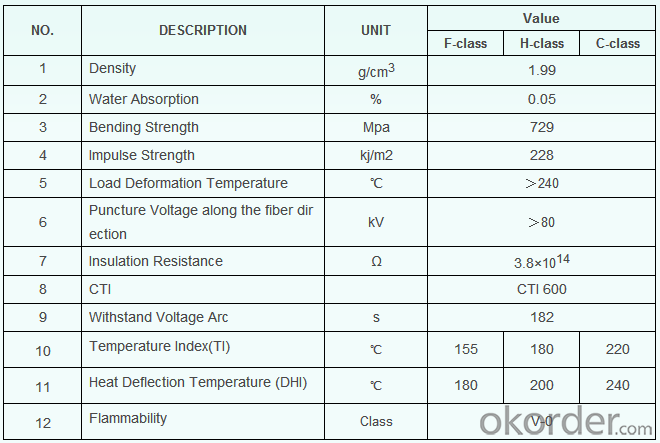

3.Technical Data Sheet

4.FAQ

a.Test Method:All the products have passed the full set of test.especially the related inspection of SGS.Our products have been sold to dozens of countries and regions,What is the most important.our products have passed all the technical inspections of most strict japanese clients.

b.Operative Norm:The operative norm of our product is JB/T10943-2010 "Brace used in Dry-type Transformer"and part of IEC60076.

c.New mold could be made according to customersrequirements.

- Q:What is the maximum length of FRP pultrusion profiles that can be manufactured?

- The maximum length of FRP (Fiber Reinforced Polymer) pultrusion profiles that can be manufactured depends on various factors such as the specific manufacturing process, equipment capacity, and transportation limitations. In general, FRP pultrusion profiles can be manufactured in lengths ranging from a few feet to several hundred feet. However, there are certain practical limitations that need to be considered. Firstly, the length of the pultrusion profiles is often limited by the size and capacity of the pultrusion equipment used in the manufacturing process. Different pultrusion machines have varying capabilities, and their length capacities can range from a few feet to over 100 feet. Manufacturers must consider the available equipment and its limitations when determining the maximum length of the profiles they can produce. Additionally, transportation and logistical constraints may also impact the maximum length of FRP pultrusion profiles. Longer profiles can be more challenging to transport due to restrictions on road transport, shipping containers, or handling capabilities. These limitations may vary depending on the region, infrastructure, and transportation methods available. It is important to note that longer profiles may also face challenges in terms of quality control and dimensional stability during manufacturing. As the length increases, it becomes more difficult to maintain consistent mechanical properties and control the curing process effectively. Therefore, while there is no fixed maximum length for FRP pultrusion profiles, it is crucial for manufacturers to consider the technical capabilities of their equipment, transportation logistics, and quality control factors when determining the practical limit for the length of their products.

- Q:Are FRP pultrusion profiles resistant to biological growth, such as mold or mildew?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles are highly resistant to biological growth, including mold and mildew. FRP materials are inherently non-porous, making it difficult for microorganisms to attach and grow on their surface. Additionally, FRP pultrusion profiles are typically manufactured using a combination of resin and glass fibers, which are both naturally resistant to biological growth. Unlike traditional materials such as wood or metal, FRP does not provide an ideal environment for mold or mildew to thrive. The smooth and non-porous surface of FRP profiles prevents moisture absorption, which is essential for the growth of microorganisms. Furthermore, FRP materials do not contain organic compounds that can support the growth of mold or mildew, making them highly resistant to biological degradation. In applications where resistance to biological growth is crucial, FRP pultrusion profiles offer a significant advantage over alternative materials. They are commonly used in environments with high humidity, moisture, or exposure to water, such as marine, agricultural, or wastewater treatment facilities. Additionally, FRP profiles are frequently employed in indoor applications where mold or mildew growth can be a concern, such as in sanitary areas or food processing plants. Overall, FRP pultrusion profiles provide excellent resistance to biological growth, including mold and mildew. Their non-porous nature, combined with the inherent resistance of the materials used in their manufacturing, make them a durable and long-lasting solution in environments where microbial growth is a potential issue.

- Q:What are the features of Glass Fiber Reinforced Plastic Pultruded materials and chairs?

- Glass reinforced plastic extruded section bar has the characteristics of unlimited length, high utilization rate of raw material, corrosion resistance, good weatherability and long service life

- Q:Can FRP pultrusion profiles be used in walkway systems?

- Yes, FRP pultrusion profiles can be used in walkway systems. FRP pultrusion profiles are lightweight, strong, and resistant to corrosion, making them suitable for use in various applications, including walkways. They offer durability, low maintenance, and can withstand heavy loads, making them a reliable choice for walkway systems.

- Q:Can FRP pultrusion profiles be used in the construction of recreational vehicles (RVs)?

- Indeed, FRP pultrusion profiles find utility in the construction of recreational vehicles (RVs). Renowned for their remarkable strength-to-weight ratio, resistance to corrosion, and durability, FRP pultrusion profiles prove to be an exemplary material for diverse applications, including RV construction. The fabrication of RVs necessitates materials that are both lightweight and robust to ensure fuel efficiency and structural integrity. FRP pultrusion profiles satisfy these requirements as they possess both lightness and high tensile strength, enabling the creation of sturdy and enduring RVs that are also lightweight and easily towed. Furthermore, FRP pultrusion profiles exhibit exceptional resistance to environmental elements such as moisture, UV radiation, and chemicals. Consequently, they prove to be suitable for outdoor applications, including RVs, where exposure to various weather conditions is inevitable. Additionally, FRP pultrusion profiles offer the advantage of effortless customization and adaptability to diverse shapes and sizes, thus meeting the design flexibility essential in RV construction. Beyond serving as structural components like frames, chassis, and supports, they can be employed for interior and exterior panels, floors, and roofs. All in all, the utilization of FRP pultrusion profiles in the construction of recreational vehicles bestows numerous benefits, including strength, durability, lightness, and resistance to environmental factors. These characteristics establish FRP pultrusion profiles as a dependable choice for RV manufacturers aspiring to fabricate high-quality, efficient, and long-lasting vehicles.

- Q:Can FRP pultrusion profiles be used in the construction of chemical storage tanks?

- Yes, FRP pultrusion profiles can be used in the construction of chemical storage tanks. FRP (Fiber Reinforced Plastic) offers excellent resistance to corrosion, making it a suitable material for storing chemicals. Pultrusion profiles provide structural support and durability, ensuring the tank's integrity. Additionally, FRP's lightweight nature, high strength-to-weight ratio, and customizable design make it an ideal choice for constructing chemical storage tanks.

- Q:Are FRP pultrusion profiles resistant to alkaline substances?

- Yes, FRP pultrusion profiles are generally resistant to alkaline substances. The composition and manufacturing process of FRP pultrusion profiles make them highly resistant to corrosion and damage caused by alkaline substances.

- Q:Are FRP pultrusion profiles resistant to fire?

- Yes, FRP pultrusion profiles are inherently fire resistant. The combination of the polymer matrix and the reinforcing fibers used in the pultrusion process provides excellent fire resistance properties, making them a suitable choice for applications where fire safety is a concern.

- Q:Are FRP pultrusion profiles suitable for the manufacturing of antenna masts?

- Yes, FRP pultrusion profiles are suitable for the manufacturing of antenna masts. FRP pultrusion profiles offer several advantages such as high strength-to-weight ratio, corrosion resistance, and excellent electrical insulation properties. These characteristics make them ideal for antenna mast construction, as they can withstand various environmental conditions and provide reliable support for antennas.

- Q:Can FRP pultrusion profiles be used in architectural or decorative applications?

- Certainly, architectural or decorative applications can definitely make use of FRP pultrusion profiles. FRP, an acronym for Fiber Reinforced Polymer, is a composite material that combines sturdy fibers like glass or carbon with a polymer resin matrix. This combination results in a material that is lightweight, durable, and resistant to corrosion, making it ideal for a variety of purposes, including architecture and decoration. The versatility of FRP pultrusion profiles lies in their ability to be manufactured in various shapes and sizes, making them highly adaptable for architectural and decorative uses. These profiles can be utilized to construct visually appealing structures such as columns, beams, and facades, all of which enhance the aesthetic appeal of buildings. Furthermore, FRP pultrusion profiles can be fabricated to imitate the appearance of other materials, such as wood or metal, enabling the creation of decorative elements that seamlessly blend into the overall design. Moreover, FRP pultrusion profiles offer several advantages over traditional materials commonly employed in architecture and decoration. They are lightweight, making them easier to handle and install, reducing labor costs. Additionally, they exhibit high resistance to corrosion, weathering, and UV radiation, ensuring long-lasting performance in outdoor applications. Furthermore, FRP profiles can be customized to meet specific design requirements, including color, texture, and surface finish, offering endless possibilities for creative expression. In summary, FRP pultrusion profiles are a viable choice for architectural and decorative applications. Their lightweight, durable, and customizable nature makes them suitable for a wide range of design needs, while their corrosion resistance guarantees longevity and low maintenance. Whether it is for structural support or decorative embellishments, FRP pultrusion profiles are an excellent option for enhancing the aesthetics and functionality of architectural and decorative projects.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Transformer And Electric Reactor Used insulation Dogbone

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 kg

- Supply Capability:

- 200000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords