Top Quality PPR Female Threaded Socket Plastic Tubes - Compliant with Food Hygiene Regulations and Non-Toxic

- Loading Port:

- Tianjin

- Payment Terms:

- L/C,T/T

- Min Order Qty:

- 2400 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Features

1. Corrosion resistance

PPR pipes and fittings can resistant to most chemical corrosion; it can withstand PH value range 1-14 high concentration of acid and alkali corrosion over a wide temperature range.

2. Installation performance

PPR pipe PPR pipe is light in weight, and the operation installation is easy, which make it available to weld again. It is very important that pipe and pipe fittings can be welded together in seconds with a simple tool. Compared to traditional connection methods it can save 40%~50% of the time.

3. Safety Indicators

The basic component of PPR is carbon and hydrogen which is simple. It keeps in line with food hygiene regulations, non-toxic. If you use PPR pipe, there will no dirt in the inner wall or “secondary water pollution” caused by rust any more.PPR pipe ,green building materials, is more suitable for transporting drinking water.

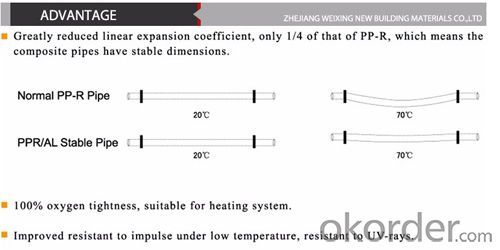

Advantages of PPR pipe

1. Maximum operating temperature can up to 95℃; it can work in a long term under the condition of 70℃ and 1.0Mpa.

2. PPR pipe density is only 1/8 of metal pipe; pressure resistance strength test is up 5Mpa, with good toughness, impact resistance.

3. Inner diameter of PPR pipe is little bigger than that of pipe fittings, which can ensure not to increase the resistance to fluid flow.

4. Inner wall of PPR pipe is smooth, no rust, no scaling, small fluid resistance

5. PPR pipe has excellent insulation properties, can significantly reduce the vibration and noise caused by the flow of liquid.

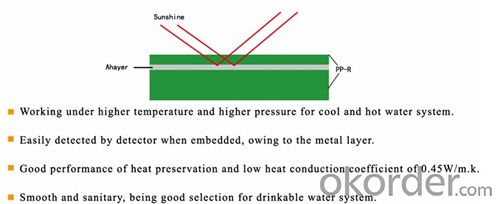

6. PPR pipe energy consumption is only 20% of steel pipe; its thermal coefficient is also only 1/200 of steel pipe, reducing heat loss greatly.

7. PPR pipe is poor electrical conductor material, which can avoid galvanic corrosion phenomena.

8. With poor thermal conductivity, PPR pipe can reduce condensation.

9. PPR pipes, fittings are recyclable.

Application

1. Hot and cold drinking water supply system of civil and industrial buildings

2. Clean, pure water piping system

3. Beverage production and transport systems

4. Industrial liquid delivery system

5. Central air conditioning system

6. Hot water circulation Heating System

7. Compressed air piping system

8. Garden and greenhouse irrigation systems

Advantages and disadvantages of PPR pipes

The full name of PP-R pipes with an international level of new energy-saving plastic products in the nineties is the random copolymer polypropylene piping. PPR installation and use of the advantages and disadvantages are as follows:

Advantages:

1. Harmless to human health, to all ions in water and chemicals in the building are no chemical reaction, compared with metal pipes do not rust, plastic water pipe will not corrode, and has a high degree of acid resistance and chloride resistance.

2. Belonging to the sustainable development green products. There is no environmental pollution in the process of production, construction and use. Secondary recovery can be repeatedly used.

3. Are different, homogeneous melt PP-R pipe is connected with other pipeline is the biggest advantage of this pipe system. Pipe connections disclose rate is very low, no maintenance, usable visual inspection, the joint firm could no corrode.

4. Light weight, easy handling construction, can greatly reduce the labor intensity, fast construction progress.

5. Good heat resistance: instant use temperature can reach 95 degrees. Long-term use at work pressure does not exceed 0.6Mpa, temperature up to 70 degrees. To meet the general needs of life and production of hot water, it is an ideal hot water pipe.

6. Low thermal conductivity: thermal conductivity of 20 degrees was 0.23 ~ 0.24W / Mk, much smaller than steel and copper. Used in air conditioning or hot water supply and drainage, you can save the investment in the pipeline insulation.

7. Elastic modulus is small: stress due to temperature change is small, suitable for direct burial, in-wall and floor surface layer Concealed way. With High-grade appearance, it is a trend of fashion.

8. Small pipe resistance: pipe wall smooth, non-furring, small head loss, head loss is smaller than the metal pipe; the local head loss is also smaller than the metal tube.

9. Performance can be repaired pipeline: full advantage of PP-R pipe hot melt, the use of PP-R of the eye of a needle stick fill holes in the pipeline repair can also be cut out the damaged pipe replacement pipe.

Disadvantages:

1. Higher cost: With the continuous promotion of the pipe is now ready to accept the price, but the price is still too high, pipe fittings, because one mold imports; Second, copper and stainless steel fittings materials pipe fittings are used in special requests these metals temperature coefficient and accessories for a temperature coefficient of PP-R materials strict consensus, now also need foreign imports.

2. PPR size is only a small outer diameter of 20-110 mm diameter products; types of fittings and valves missing, there is connected to the metal valves inconvenient questions.

3. Rigidity and impact resistance worse than metal pipes.

4. Larger coefficient of linear expansion, for surface or overhead required to lay more pipe hangers, affect the appearance.

5. Construction equipment advanced complex, construction technology requirements, construction workers and construction quality management requirements high. Joint quality and temperature of the hot melt connection, heating time, the seam stress-related, construction prone to bias.

6. UV resistance is poor, in the long sunlight easy to aging.

7. PP-R pipe belonging to combustible materials, it cannot be used for fire water supply system.

- Q:Can plastic tubes be used for architectural lighting installations?

- Yes, plastic tubes can be used for architectural lighting installations. They are lightweight, flexible, and can be easily shaped and manipulated to fit various architectural designs. Additionally, plastic tubes are durable, cost-effective, and can provide diffused lighting effects, making them a popular choice for architectural lighting installations.

- Q:Are plastic tubes resistant to moisture absorption?

- Yes, plastic tubes are generally resistant to moisture absorption.

- Q:Are plastic tubes resistant to warping under high temperatures?

- Yes, plastic tubes are generally resistant to warping under high temperatures. However, the specific resistance of plastic tubes to warping can vary depending on the type of plastic used. Some plastics are more heat-resistant than others and can withstand higher temperatures without warping.

- Q:Will they disintegrate or damage over time? Or are they safe like that for a while?

- If you must store them for a long time get a tube that is acid free and that will hold out moisture. A plastic type tube. If you keep it dry and at normal room temperature, storing it in a tube is fine long term. Maybe even years. Do not roll tightly.

- Q:How are plastic tubes labeled for identification?

- Plastic tubes are commonly labeled for identification using various methods such as adhesive labels, heat shrink sleeves, direct printing, or color coding.

- Q:I've been trying to study the types of fittings that are used to transmit fluids and I thought you could help me out with this concepts. Thank you.PS. English is not my first language, that's why I need assistance :D

- Answer A: Tubing normally has separate connectors, while hoses have integral/attached connection fittings. Answer B: If you've ever been hosed, you'd know the difference. Think of a rubber or vinyl garden hose or a canvas/cloth fire hose. Now think of copper, plastic or rubber tubing. Used similarly, constructed slightly differently in some cases, sometimes indistinguishable, sort of different ends of a spectrum with a meeting/overlap point somewhere toward the center of the category. Hoses can carry water or liquids, tubing can, also, but is used for gases under pressure, as well. Tubing, to put a fine point on the topic, generally has greater lateral/sidewall rigidity and strength than hoses.

- Q:PR plastic tubes, everyone said, permanent, a great harm to health, even drinking water is a problem?

- 1) change the water pipe: the longer the PPR pipe is used, the greater the poison, or the regular flushing and disinfection of the old pipe.2) install pre filter and cabinet water purifier in old pipe line3) new home water pipes customers can study in Europe and the United States, the family installed plastic copper pipe (slightly higher price) or lined with copper PPR tube (moderate price). Because copper has excellent sterilization function and self-cleaning function, it is most suitable for family use.

- Q:I'm talking about toothpaste, hand cream, hair products, etc. They changed their packaging so that you can't roll the bottom up anymore. It unrolls and it is almost impossible to get the rest of the product. Today I just cut the bottom off!

- Ha! You figured out as I did. It's the only way to get the last drops from the top of the tube. Hulk Hogan isn't strong enough to squeeze the last part out.

- Q:Can plastic tubes be used for fluid transfer in manufacturing processes?

- Yes, plastic tubes can be used for fluid transfer in manufacturing processes. Plastic tubes offer various benefits such as corrosion resistance, flexibility, and affordability, making them suitable for a wide range of applications. They can efficiently transport fluids like liquids, gases, and even chemicals, ensuring smooth operations in manufacturing processes.

- Q:How can a PPC plastic pipe be broken?

- First, you should turn off the tap valve, and then observe the leak point to see what is happening at the break.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Top Quality PPR Female Threaded Socket Plastic Tubes - Compliant with Food Hygiene Regulations and Non-Toxic

- Loading Port:

- Tianjin

- Payment Terms:

- L/C,T/T

- Min Order Qty:

- 2400 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords