Colored Polypropylene Tubing

Colored Polypropylene Tubing Related Searches

Geomembrane In Road Construction Construction Glass Polypropylene Tape Construction Specialties Corner Guards Geotextile Mesh Perri Construction Polypropylene Mesh Nonwoven Wallpaper Fabric Duct Geotextile Fabric BrisbaneHot Searches

Stainless Steel Tubing Supplier Stainless Steel Tubing Sizes Stainless Steel Tubing Near Me Bidim Geotextile Price polypropylene pipe specifications Masonry Construction Type Real Estate Builders & Construction Company Geotextile Membrane Suppliers Bidim Geotextile Price polypropylene pipe specifications Masonry Construction Type Geotextile Fabric Cost Per Square Foot Real Estate Builders & Construction Company Geotextile Filter Fabric Prices Geotextile Filter Fabric Specification Geotextile Fabric Types Geogrid Fabric Near Me Textilene Fabric Suppliers Uk Geotextile Membrane Suppliers Terratex Nonwoven GeotextilesColored Polypropylene Tubing Supplier & Manufacturer from China

Okorder.com is a professional Colored Polypropylene Tubing supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Colored Polypropylene Tubing firm in China.Hot Products

FAQ

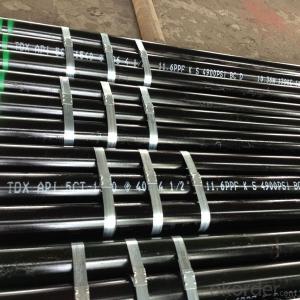

- There are several limitations to using steel pipes in various applications. Firstly, steel pipes can be quite expensive compared to other materials such as plastic or copper. This cost factor can be a significant limitation for projects with tight budgets. Secondly, steel pipes are susceptible to corrosion. Over time, exposure to moisture and certain chemicals can cause steel pipes to rust and deteriorate. This can lead to leaks, reduced structural integrity, and ultimately, the need for costly repairs or replacement. Another limitation of steel pipes is their weight and rigidity. Steel pipes are generally heavier and less flexible than other types of pipes, making them more challenging to install and maneuver in certain settings. Additionally, their rigid nature makes them less suitable for applications that require significant movement or flexibility. Furthermore, steel pipes can be prone to thermal expansion and contraction. When exposed to extreme temperatures, steel pipes can expand or contract, potentially causing stress on joints, fittings, or other components. This can lead to leaks or even pipe failure if not properly accounted for. Lastly, steel pipes are not as resistant to certain chemicals or substances as other materials. Some chemicals can corrode or erode the inner lining of steel pipes, compromising their integrity and potentially causing contamination or leakage. While steel pipes have many advantages, it is important to consider these limitations when deciding on the most suitable material for a specific application.

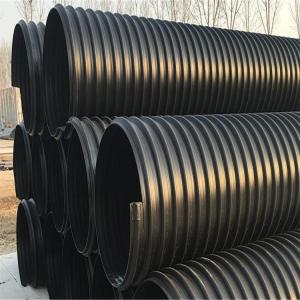

- Yes, steel pipes are suitable for underground sewage lines. They are strong, durable, and resistant to corrosion, making them an excellent choice for sewage systems.

- SC15 what does galvanized steel pipe look like?

- DN15 galvanized pipe, nominal diameter of 15mm

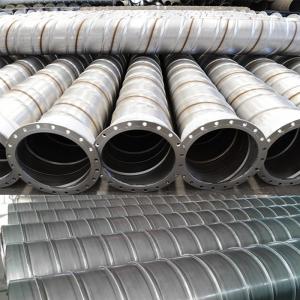

- There are several types of steel pipe flanges, including slip-on flanges, weld neck flanges, socket weld flanges, threaded flanges, lap joint flanges, and blind flanges. Each type has its own unique design and application, catering to various piping systems and requirements.

- What's the difference between hot-rolled seamless steel tube and cold-rolled seamless steel tube?

- Hot rolled seamless tubes are divided into ordinary steel tubes, low and medium pressure boiler tubes, high pressure boiler tubes, alloy steel tubes, stainless steel pipes, oil cracking pipes, geological steel pipes and other steel pipes, etc..

- Steel pipes are renowned for their resistance to impact and external forces. Their high strength and durability render them perfect for a wide range of applications, notably in the realm of piping. These pipes possess the remarkable ability to endure external forces, encompassing impact, pressure, and vibrations. Consequently, industries necessitating steadfast and robust piping systems, like oil and gas, construction, and infrastructure, frequently opt for steel pipes. Furthermore, when confronted with extreme conditions, steel pipes are less prone to cracking or breaking in comparison to other materials. Nonetheless, the extent of resistance to impact and external forces may hinge upon the specific grade and thickness of the steel employed in the pipes.

- Steel pipes are used in the manufacturing of ships for various purposes, such as carrying fluids and gases, providing structural support, and facilitating efficient operation of the ship's systems. They are used for plumbing, ventilation, and firefighting systems, as well as for the construction of hulls and other vital components. Overall, steel pipes play a crucial role in ensuring the functionality and safety of ships during their construction and operation.

- How can galvanized steel tubes be painted on the surface?

- Suitable for galvanized base material (antirust primer), epoxy zinc yellow primer (double component), epoxy ester zinc yellow primer.Pretreatment of galvanized sheet when brushing:1, conditional, you can zinc plating phosphating treatment, or first spray a layer of phosphating primer.2, or smooth zinc plating surface sweeping treatment.3, the galvanized workpiece, galvanized pipe surface with solvent (that is, epoxy zinc yellow primer, thinner) wipe, in order to remove the workpiece crude oil protective layer, and increase cleanliness.4, two-component epoxy zinc yellow primer: in strict accordance with the proportion of paint and curing agent paint, and aging 30 minutes later, modulation suitable construction viscosity, you can spray.One component epoxy ester primer: zinc yellow construction viscosity suitable to construction of modulation, the correct construction method.